Universal workpiece supporting seat

A support seat, a general-purpose technology, applied in the direction of support, metal processing machinery parts, manufacturing tools, etc., can solve problems such as drilling errors, workpiece swings, and unreliable compression of workpieces, so as to avoid interference, reduce weight, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

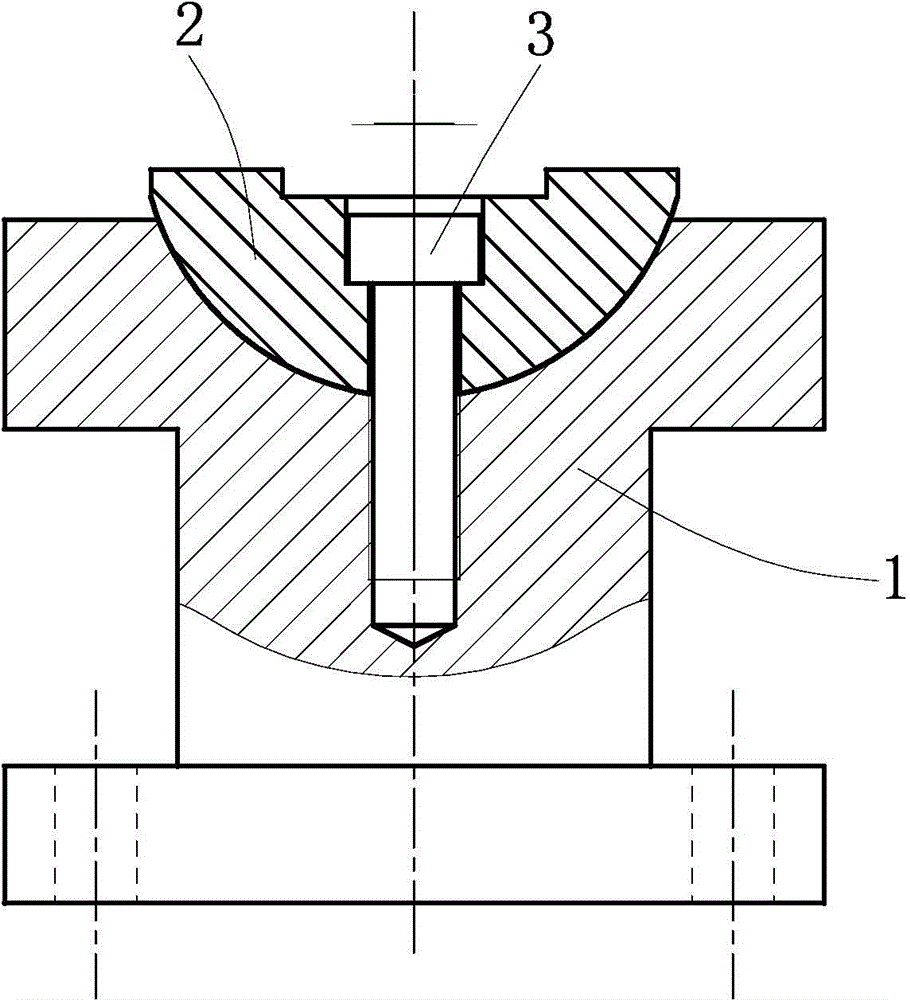

[0015] Such as figure 1 , figure 2 As shown, a general-purpose workpiece support seat is mainly composed of three parts: a rectangular fixed block 1, a floating block 2 and a fastening countersunk screw 3.

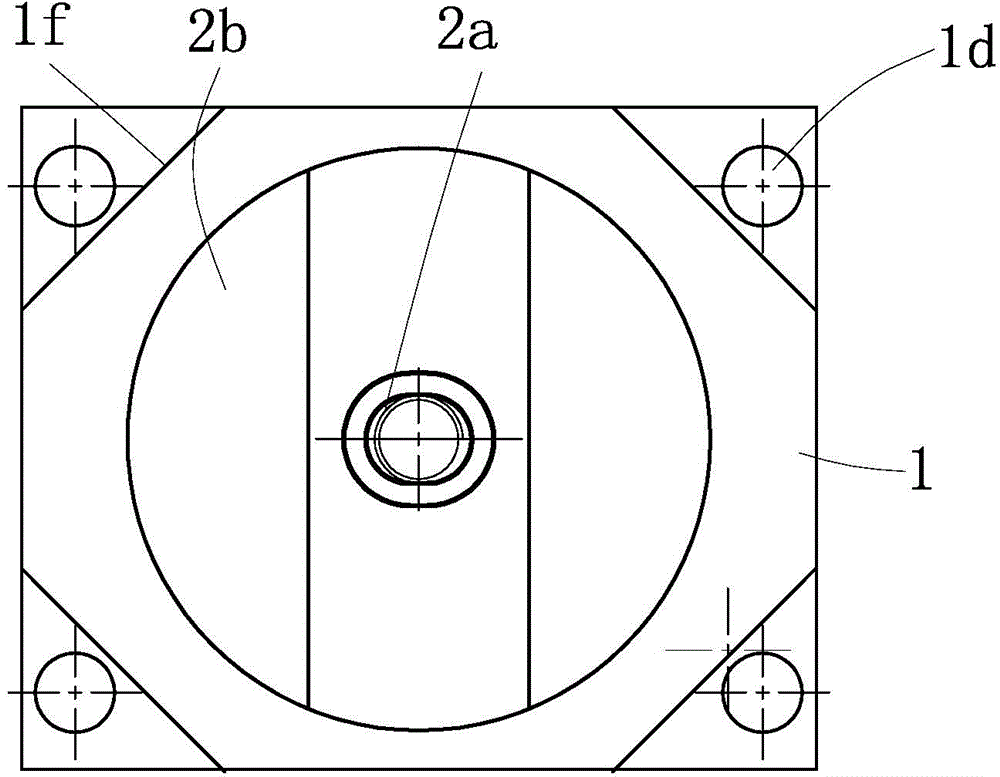

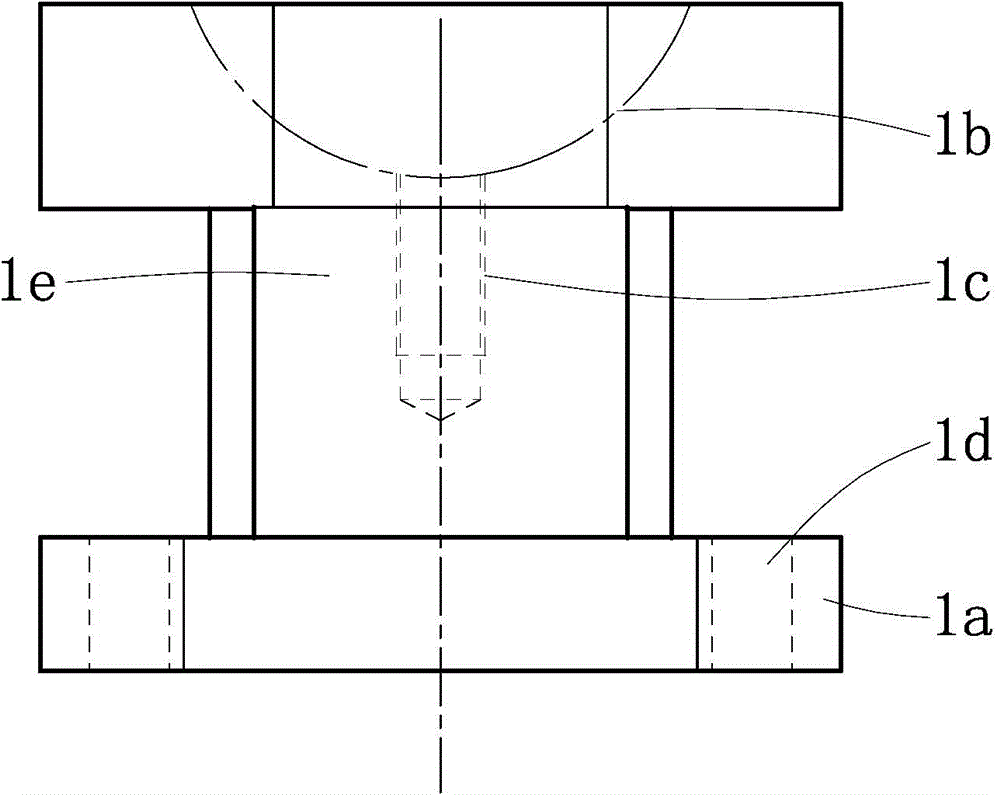

[0016] combine figure 1 —— Figure 4 As shown, a rectangular mounting base 1a is provided at the bottom of the rectangular fixing block 1, and a mounting hole 1d is provided on the rectangular mounting base 1a for connecting with the workbench of the vertical drilling machine. Preferably, there are four mounting holes 1d arranged in a rectangular shape, but the number of mounting holes 1d is not limited to four. A spherical groove 1b is arranged on the top of the rectangular fixing block 1, and a threaded blind hole 1c extending downward is arranged in the middle of the spherical groove 1b.

[0017] The floating block 2 is a hemispherical block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com