Spandex from high molecular weight poly (tetramethylene-co-ethyleneether) glycols

一种四亚甲基、亚乙基醚的技术,应用在纤维化学特征、单组分聚脲人造长丝、单组分聚氨酯人造长丝等方向,能够解决没有公开使用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

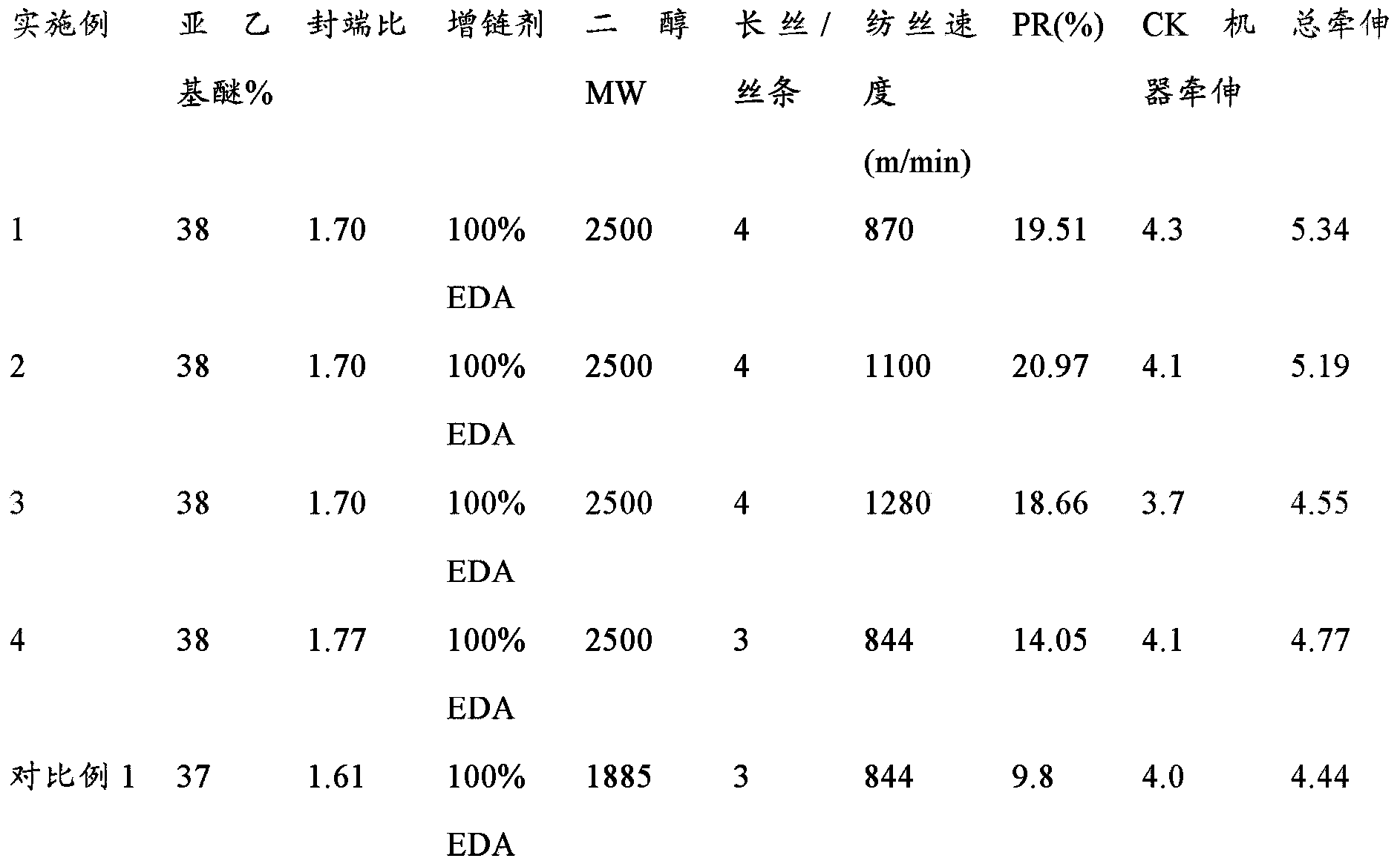

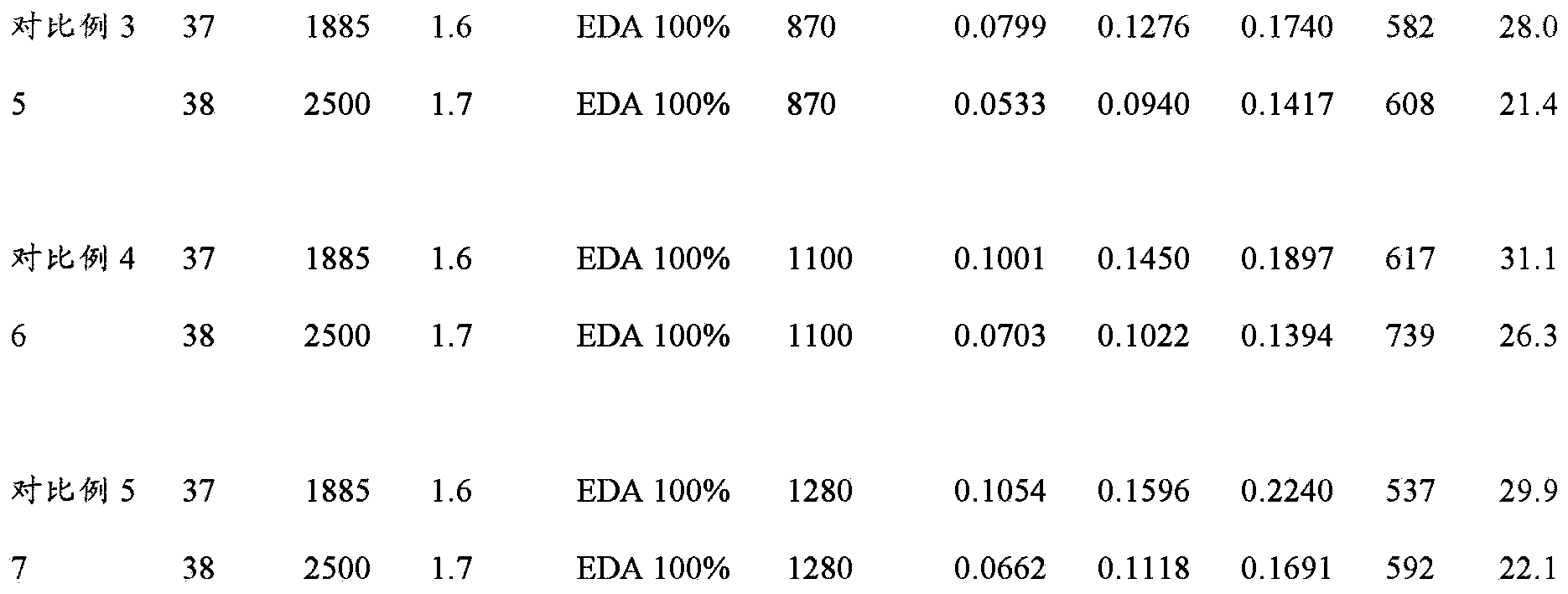

[0080] Embodiment 1-15 (elastic fiber containing ethylene ether of high molecular weight)

[0081] Random poly(tetramethylene-co-ethylene ether) glycols having mole percent ethylene ether units and number average molecular weights as shown in Tables 1-4, at 90° C. with 1-iso Cyanato-4-[(4-isocyanatophenyl)methyl]benzene was capped for 120 minutes using 100 ppm of mineral acid as catalyst to obtain diisocyanate-diol molar ratio (capping ratio) of the prepolymer. This capped diol was then diluted with DMAc solvent, chain elongated with EDA, and chain terminated with diethylamine to give a spandex polymer solution. The amount of DMAc used was such that the final spinning solution had 30-38 wt% polyurethaneurea therein, based on total solution weight, unless otherwise stated. The spinning solution was dry spun into a column with dry nitrogen, condensed, passed around godet rolls, and wound at the speeds listed. The spinning chamber temperature and suction gas flow were adjusted...

Embodiment 16

[0101] Random poly(tetramethylene-co-ethylene ether) glycol, it has the ethylene ether unit of 49mol% and the number average molecular weight of 2045, is combined with 1-isocyanato-4- at 90 ℃ [(4-Isocyanatophenyl)methyl]benzene was capped for 120 minutes using 100 ppm of mineral acid as catalyst. The molar ratio of diisocyanate to diol was 1.64. This capped diol was then diluted with DMAc solvent, chain elongated with EDA, and chain terminated with diethylamine to give a spandex polymer solution. The amount of DMAc used was such that the final spinning solution had 38 wt% polyurethaneurea therein, based on total solution weight. The spinning solution was dry spun into a column with dry nitrogen at 440°C, condensed, passed around a godet roll, and wound at 869 m / min. The filaments provide good spinnability. The spandex has a tenacity of 0.62 g / denier and an elongation of 580%.

Embodiment 17-21

[0120] Atactic poly(tetramethylene-co-ethylene ether) glycol, which has 49 mol% of ethylene ether units and a number average molecular weight of 2443, was prepared with 1-isocyanato-4- [(4-Isocyanatophenyl)methyl]benzene was capped for 120 minutes using 100 ppm of a homogeneous mineral acid as a catalyst to give a 3.5% NCO prepolymer. The molar ratio of diisocyanate to diol was 2.26. This capped diol was then diluted with DMAc solvent for chain extension using BDO (1,4-butanediol) to give a spandex polymer solution. It is also possible and common practice in spandex technology to add chain terminators to the formulation to control molecular weight and other properties. Chain terminators are not equally necessary for polyurethane formulations, where polyurethanes tend to be more soluble and have less propensity for hard segments relative to increasing the apparent molecular weight of the polymer. This above general procedure was adapted and used to form Examples 18, 19, 20 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com