Drill rod automatic treatment device

A technology for automatic handling and drilling of drill pipes, applied in the direction of drill pipes, drill pipes, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

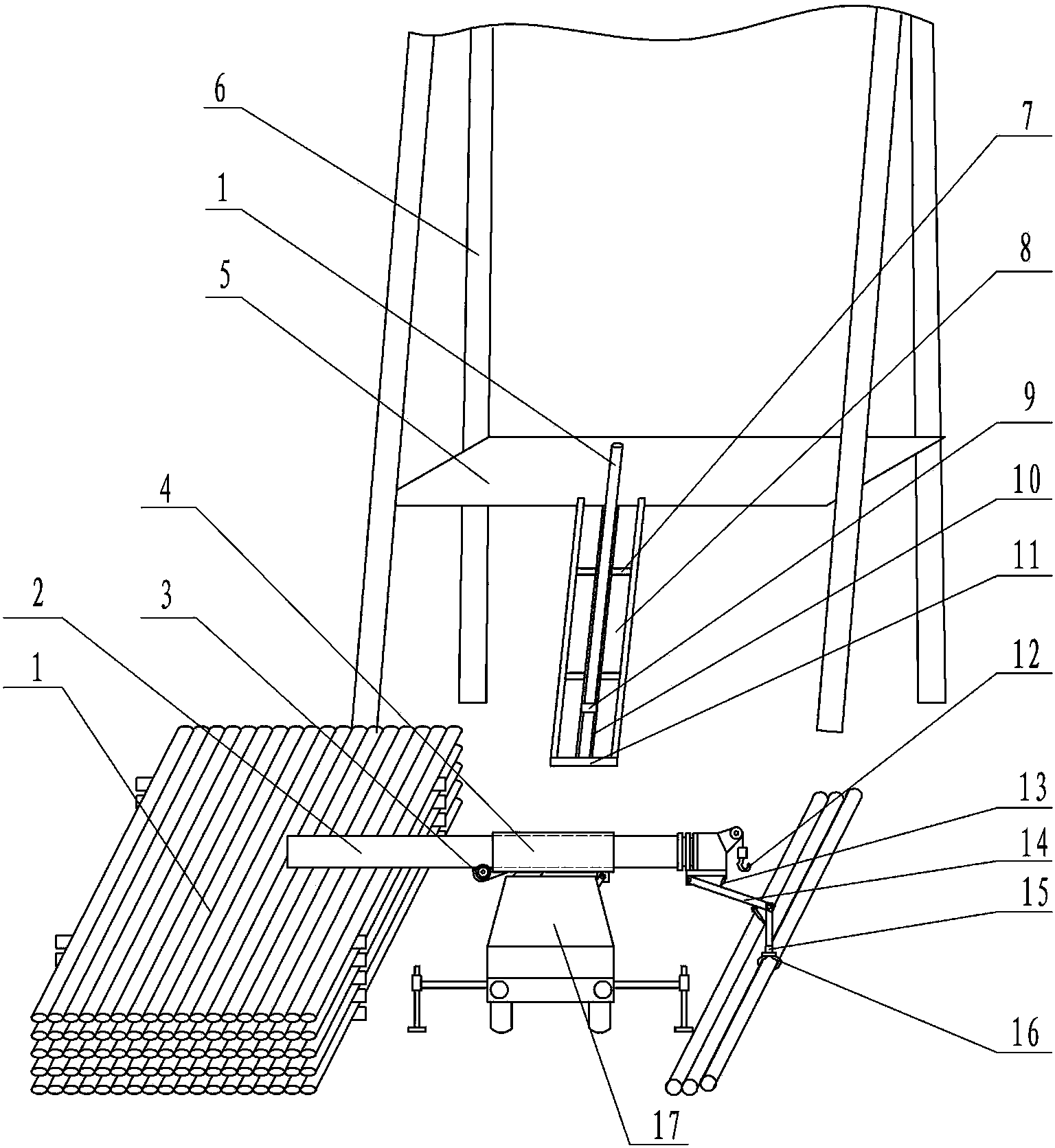

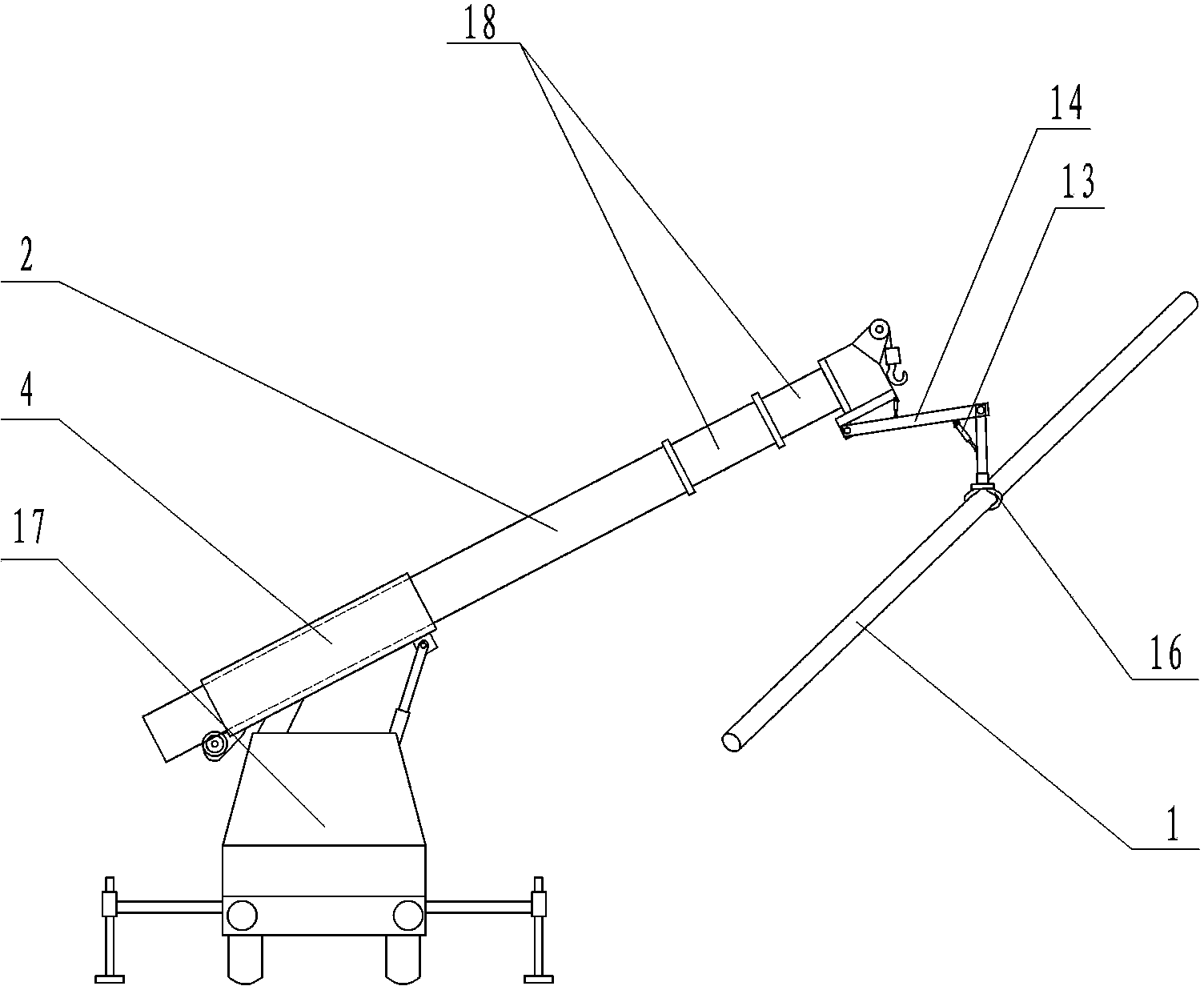

[0012] figure 1 A slideway 10 is arranged in the middle of the ramp 8 in front of the Zhongjing platform 5, and the upper and lower sides of the slideway 10 are symmetrically arranged with a pipe row block 7. The outer ends of the pipe row block 7 can be raised and inclined to the slideway. Clamp nearby drill pipe.

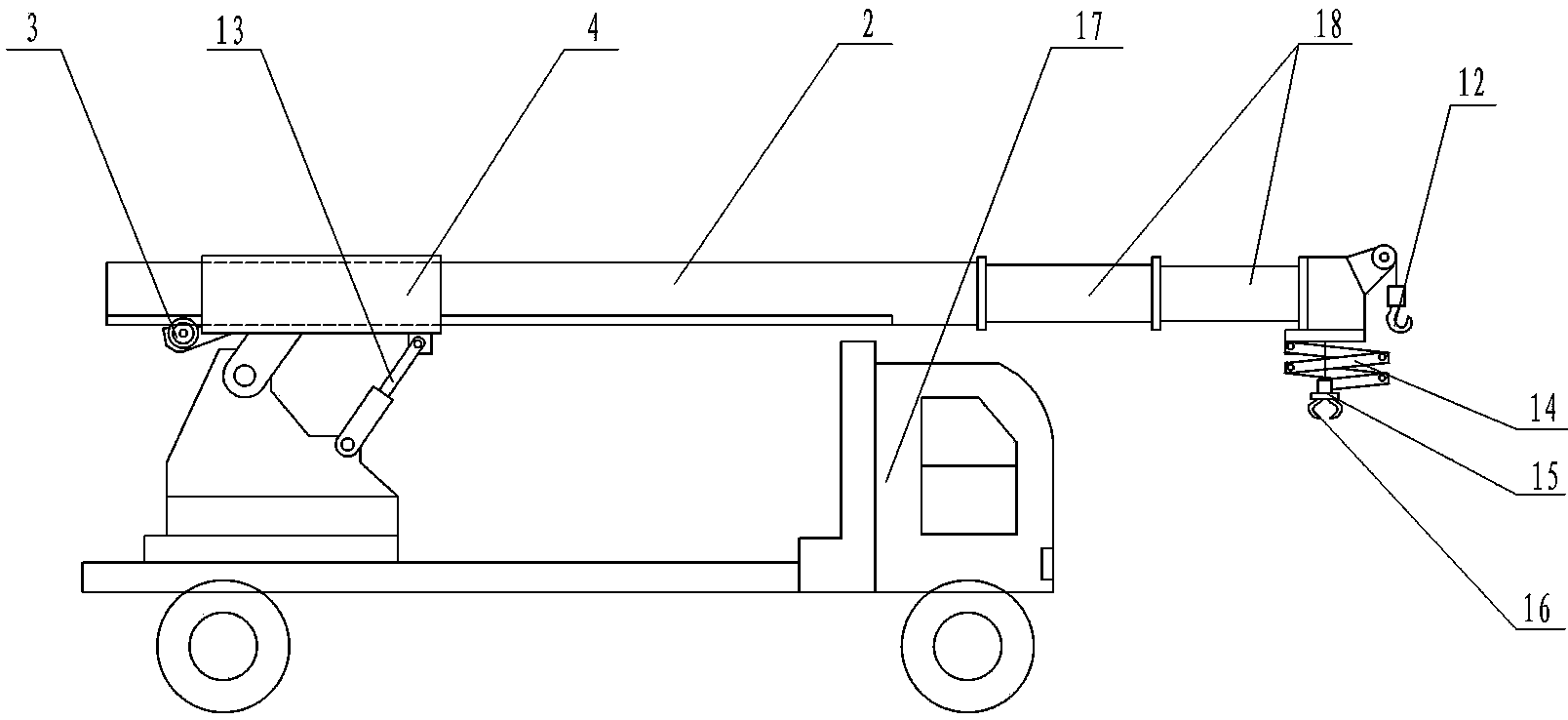

[0013] figure 2 Middle is the horizontal zoom-in view of the automatic drill pipe handling vehicle. A boom base 4 is arranged at the rear of the main boom 2 of a general truck crane. There is a splint on the bottom left side of the boom base 4 to be hinged with the upper part of the truck crane turntable, and the right side is connected with the car turntable by a hydraulic cylinder (comprising a piston rod) 13. The lower left end of the boom seat 4 is provided with a main boom driving device 3, which has two modes of gear drive and wire rope drive. What draw among the figure is gear drive, and what drive with gear just is provided with rack at one side below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com