Aqueous high-temperature-resistant enamel paint, and preparation method and construction method thereof

A technology of high temperature resistance and enamel, which is applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as environmental pollution, softening, and poor surface decoration effect of high temperature resistant coatings, and achieve applicability Wide and good outdoor weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

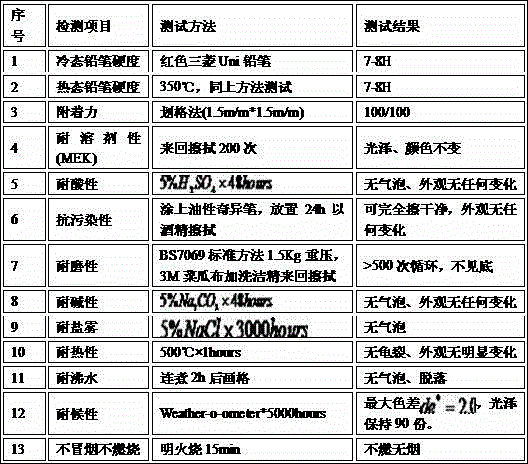

Image

Examples

preparation example Construction

[0089] The preparation method of water-based high temperature resistant enamel paint of the present invention comprises the following steps:

[0090] (1) Add silica sol and aluminum sol into the reaction tank, then add dispersant, defoamer, and leveling agent in a certain weight ratio under slow (300-500 rpm) stirring, and stir for 20 Minutes, form base paint binder A after stirring evenly, stand-by;

[0091] (2) Potassium tartrate is mixed with water to form a solution with a concentration of 15-80% and evenly mixed with a titanate coupling agent to form a gelling curing agent B for use;

[0092] (3) Stir the inorganic high-temperature pigment, rutile titanium dioxide, nano-titanium dioxide inorganic high-temperature pigment, water-based silica sol grinding body, dispersant and defoamer according to a certain weight ratio, and then grind it in the grinder to fineness Less than 20μm, forming a color paste;

[0093] (4) According to the needs, fully mix the binder, gelling cu...

Embodiment 1

[0095] Embodiment one: Binder preparation: clean the reaction tank container and high-speed dispersion equipment, wash them with deionized water, add silica sol and aluminum sol into the reaction tank, and then add dispersant, defoamer, leveling agent in turn under slow stirring agent. After stirring fully and evenly, binder A is formed, ready for use.

[0096] The formula weight is as follows: 62.5 parts of silica sol

[0097] Aluminum sol 12.0 parts

[0098] Dispersant Byk346 0.1 parts

[0099] Defoamer Byk037 0.2 parts

[0100] Leveling agent Byk450 0.2 parts

[0101] (2), after making potassium tartrate water into a solution with a concentration of 30-60%, mix evenly with 80 parts by weight of potassium tartrate solution and 5 parts of titanate coupling agent to form a gelling curing agent B for use;

[0102] (3) Stir the inorganic high-temperature pigments, rutile titanium dioxide, nano-titanium dioxide...

Embodiment 2

[0119] The composition ratio of this embodiment is as follows:

[0120] The adhesive is made of the following components by weight:

[0121] Silica sol 80 parts

[0122] Dispersant 0.3 parts

[0123] 0.3 parts of defoamer

[0124] Leveling agent 0.3 part

[0125] The gel curing agent is made of the following components by weight:

[0126] Potassium tartrate solution 70 parts

[0127] Titanate coupling agent 3.0 parts

[0128] The color paste is made of the following components by weight:

[0129] Nano titanium dioxide 2 parts

[0130] Inorganic high temperature pigment 8 parts

[0131] Water-based silica sol grinding body 40 parts

[0132] Dispersant and defoamer 0.3 parts.

[0133] The processing method and construction method of this embodiment are the same as those of the embodiment, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com