Bending-resistant part

A component and side plate technology, applied in the field of bending parts, can solve the problems of threatening the safety of the structure, damage to the longitudinal reinforcement at the end of the beam, and high repair costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

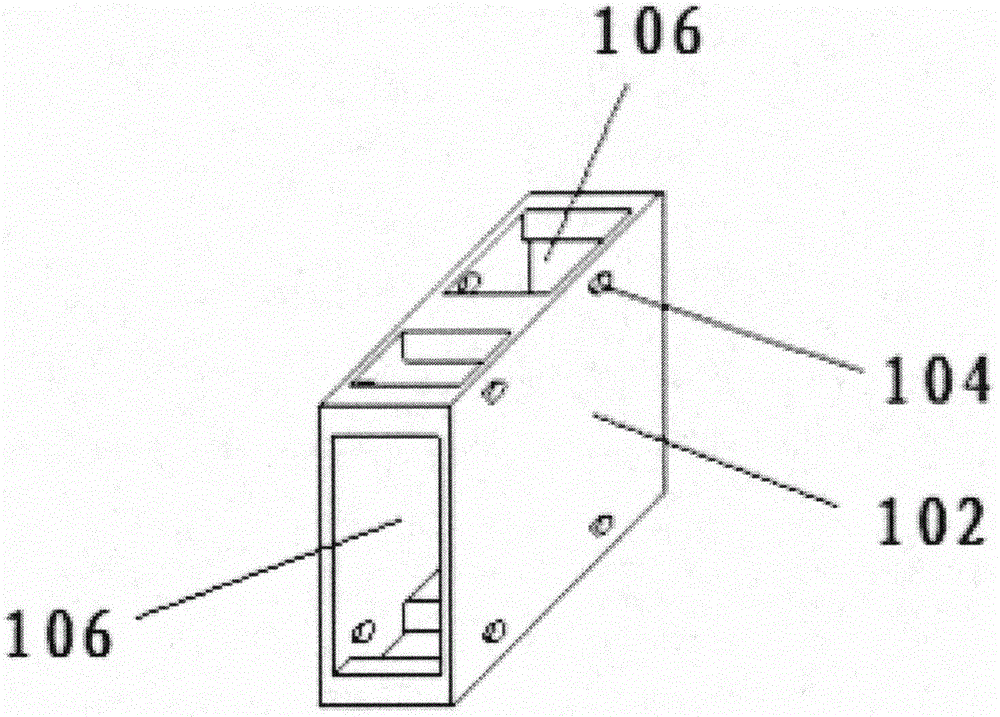

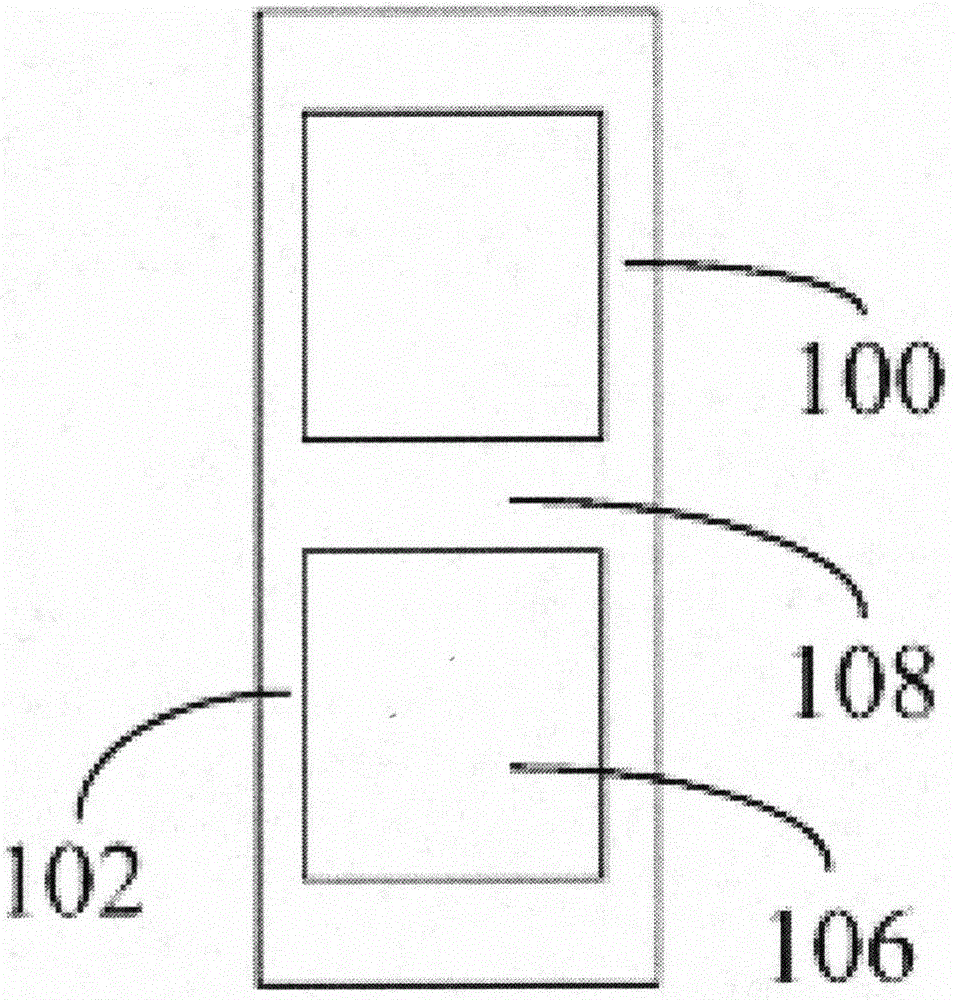

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 , figure 2 As shown, the anti-bending part is used to connect the beam and the column. The anti-bending part is a cuboid structure made of metal. The anti-bending part has a first side plate 100 close to the beam and a second side plate 102 close to the column. The first side plate 100 and the second side plate 102 are close to the column. The second side boards 102 are provided with installation holes 104 , and the surfaces adjacent to the first side board 100 and the second side board 102 are provided with fastening holes 106 . The anti-bending part is a rectangular parallelepiped structure, the first side plate 100 and the second side plate 102 are parallel, and the remaining six surfaces of the anti-bending part are provided with fastening holes 106 . The function of the mounting hole 104 is to facilitate the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com