Pulling strip type non-setting adhesive

A pull-tab type, adhesive layer technology, applied in the field of self-adhesive, can solve the problems of users’ difficulty in separating the backing paper and inconvenient use, and achieve the effect of saving labeling time and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

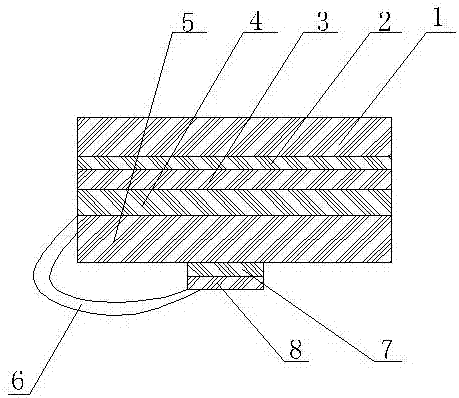

[0014] Embodiment 1: A pull-tab type self-adhesive, including a body and a pull-tab 6, the body sequentially includes a face paper 1, an adhesive layer 2, a hard paper layer 3, a self-adhesive layer 4, and a bottom from top to bottom Paper 5, one end of the draw tape 6 is fixedly connected to the backing paper 5, and the other end is connected to the surface of the backing paper 5. The surface of the base paper 5 is provided with a first pasting unit 7, and the outer end of the draw tape 6 is provided with a second pasting unit 8, and the first pasting unit 7 and the second pasting unit 8 form a pasting fit, which can effectively prevent pulling. Bring 6 scattered.

Embodiment 2

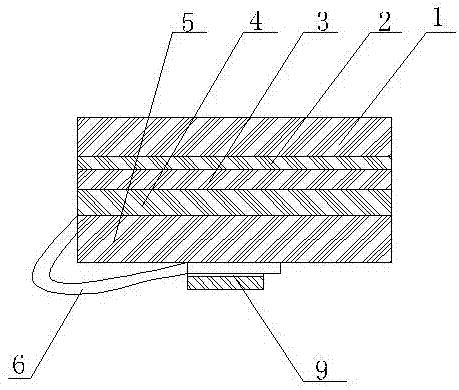

[0015] Embodiment 2: A drawstring-type self-adhesive, including a main body and a drawstring 6, the main body sequentially includes a face paper 1, a glue layer 2, a hard paper layer 3, a self-adhesive layer 4, and a bottom from top to bottom Paper 5, one end of the draw tape 6 is fixedly connected to the backing paper 5, and the other end is connected to the surface of the backing paper 5. The surface of the base paper 5 is provided with a perforation 9, and the perforation 9 forms an insertion fit with the drawstring 6, which can effectively prevent the drawstring 6 from being scattered.

[0016] The user twists the drawstring 6 and pulls it out. Due to the existence of the hard paper layer 3, the body has a certain bending resistance, and the user can easily and quickly peel off the backing paper 5, which is convenient for the user to paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com