Separating and dedusting recovery system based on coring drilling construction

A recovery system and coring technology, which is applied in earthwork drilling, wellbore/well components, construction, etc., to achieve the effects of high automation, environmental protection and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] The present invention will be further described below with reference to the drawings and embodiments.

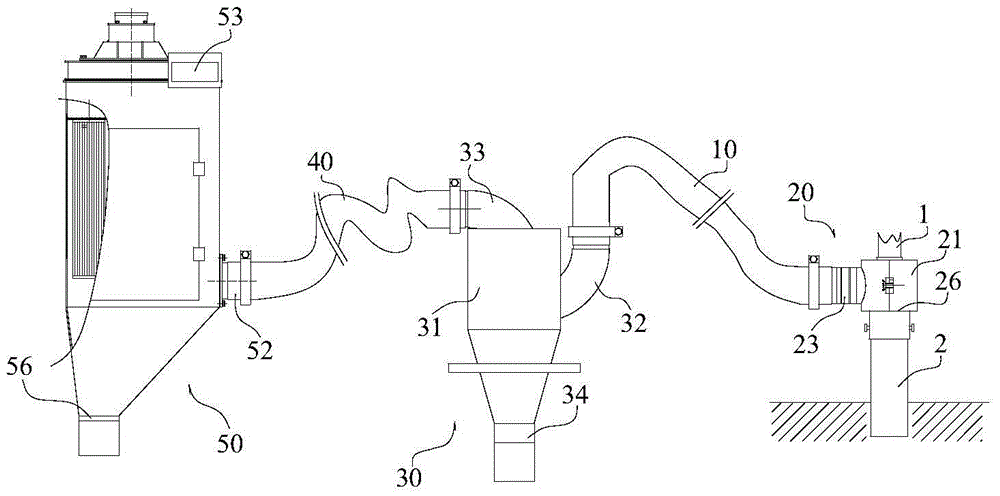

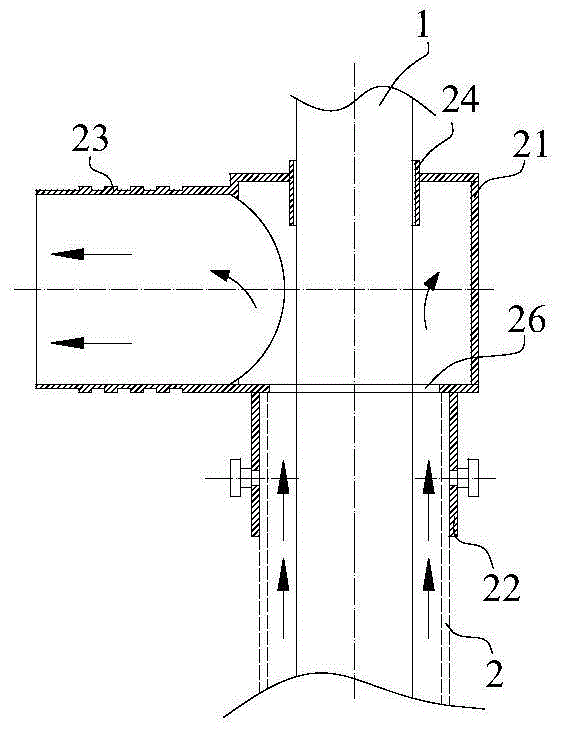

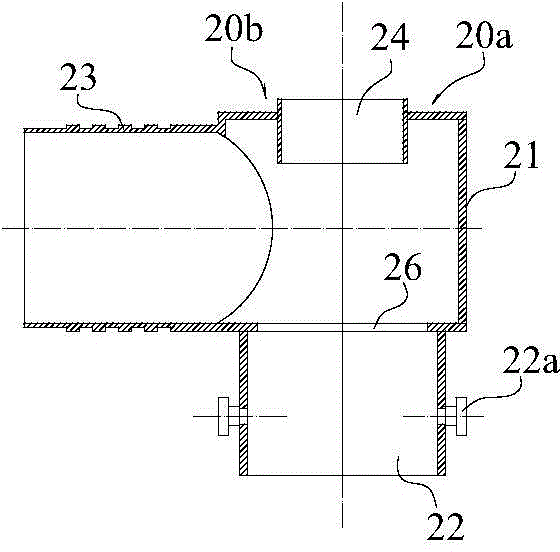

[0021] Reference figure 1 The separation dust removal and recovery system based on drilling and coring construction of the present invention includes: a recovery device 20, sleeved on the drill pipe 1 and fixedly installed at the upper end of the pipe casing 2, with a recovery shell 21 and a recovery chamber communicating with it The recovery outlet end 23, the recovery inlet end 26; the separation device 30, which has a separation shell 31 and a separation inlet end 31, a separation outlet end 33, and a solid-liquid discharge end 34 communicating with its separation chamber; the dust removal device 50 has a collection shell 51 and the collection inlet end 52 communicating with the collection chamber, the exhaust channel 53, and the dust collection port 56; the suction generating device generates suction in the exhaust channel 53. The recovery outlet end 23 is connected ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap