Emitted gas adjusting mechanism of semi-automatic shotgun

An adjustable structure and semi-automatic technology, applied in the field of firearms, can solve problems such as difficulty in meeting the energy demand of automatic circulation, affecting the energy of the automatic machine system, bomb feeding and shell ejection failures, etc., to reduce the probability of air guide holes, prevent shell ejection failures, Ensure the effect of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

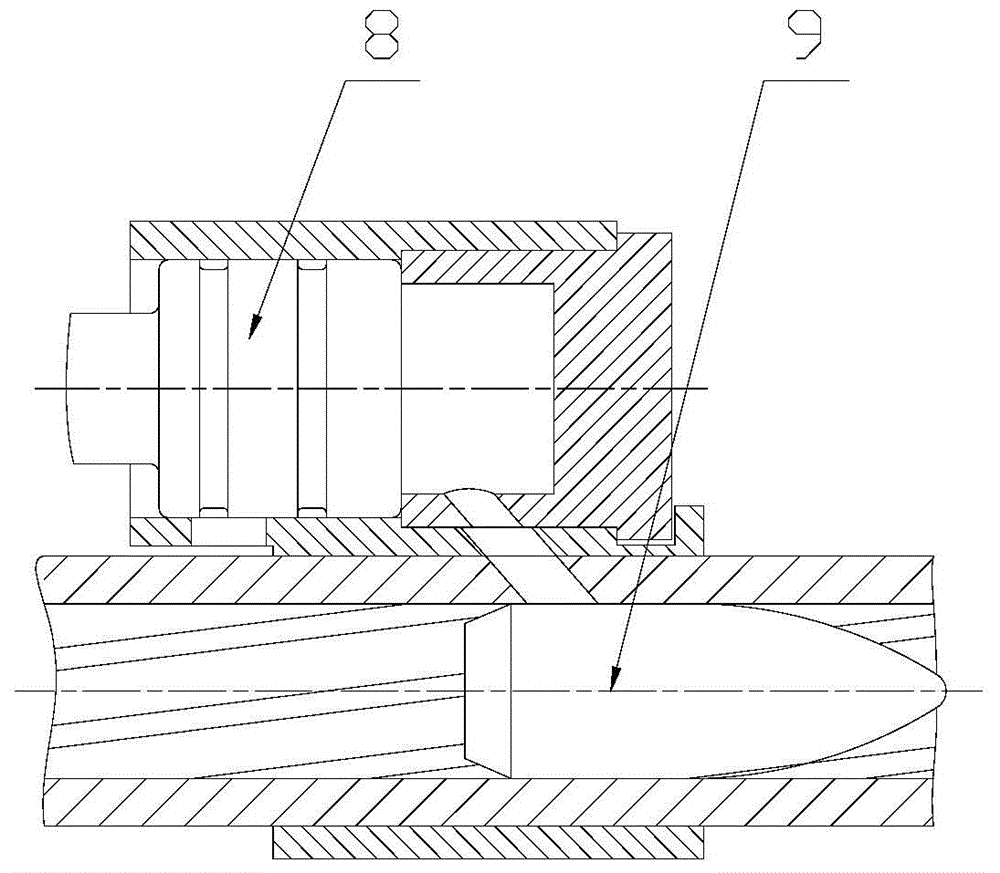

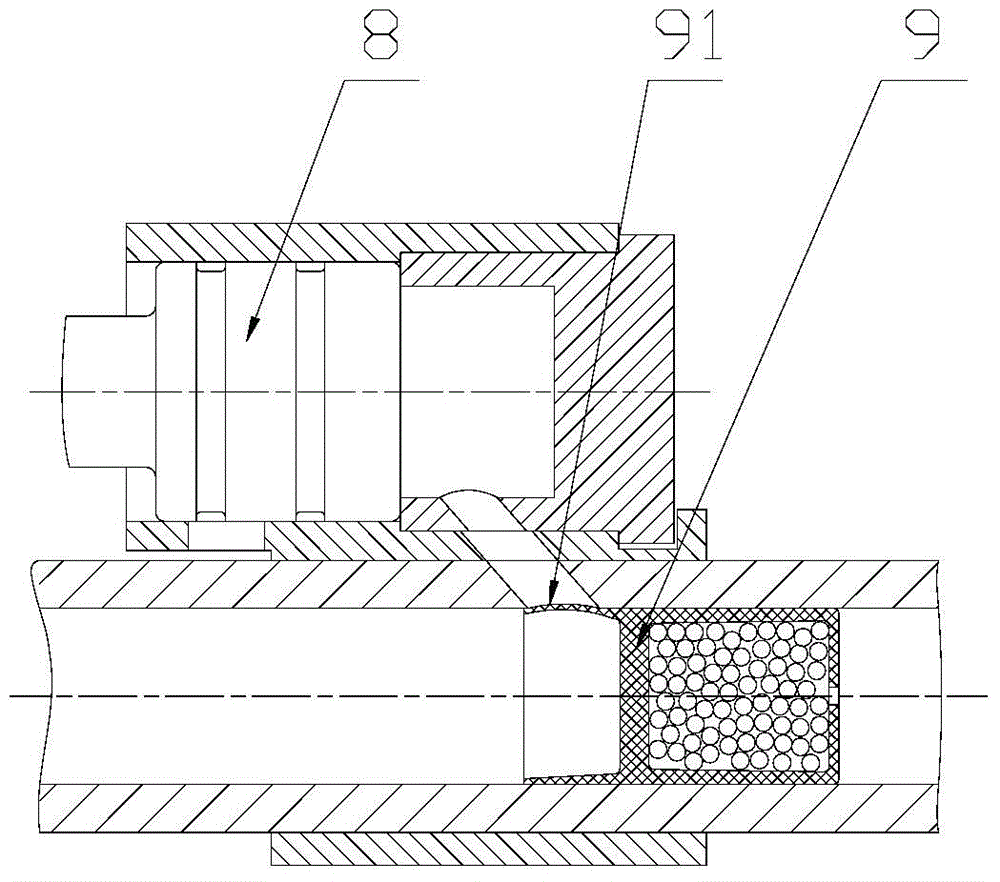

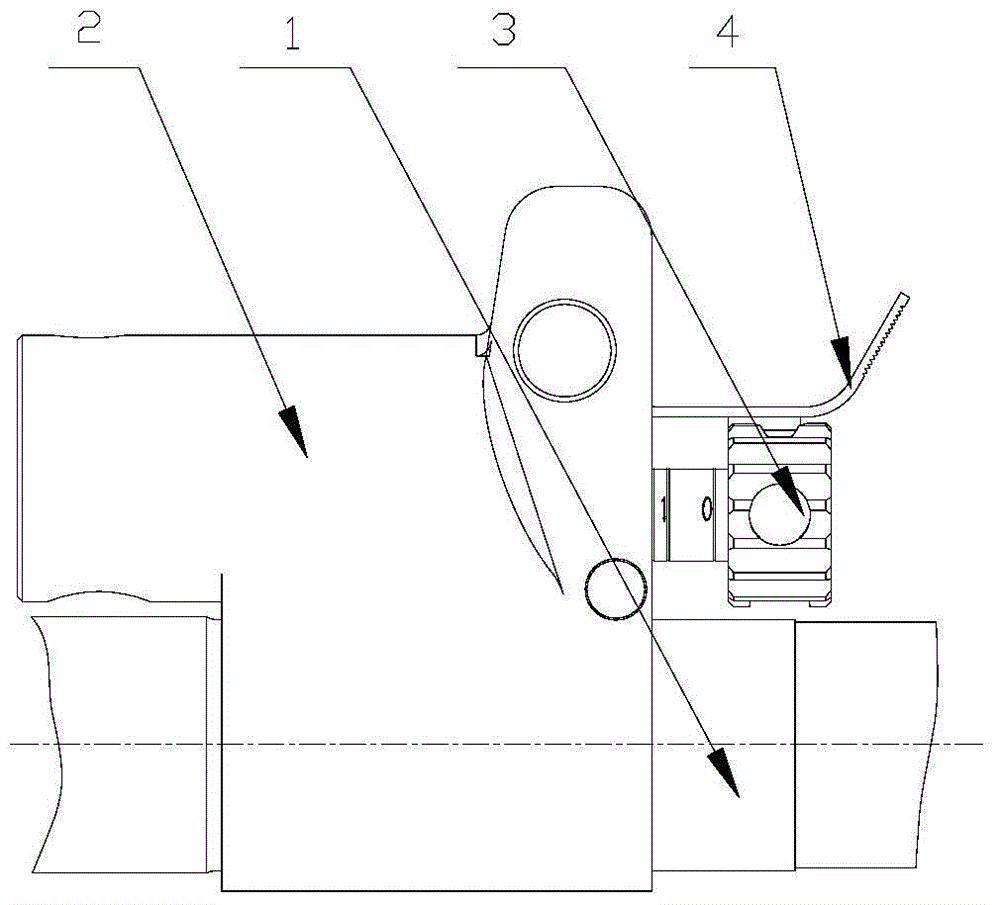

[0026] see image 3 , Figure 4 , Figure 5 , is an embodiment of the gas guide adjustment structure of the semi-automatic shotgun, including the gun barrel 1 of the semi-automatic shotgun, and the upper part of the gun barrel 1 is fixed with the gas guide block 2. In this embodiment, the gas guide block 2 is sleeved on the gun barrel through a connecting sleeve , and locked by bolts for easy disassembly. The second half of the gas block 2 is an air chamber 21 for installing the piston 8 , and a vent hole 21 a is provided on the wall of the second half of the air chamber 21 . The front half of the gas block 2 is a regulator installation section 22, and the rear portion of the regulator installation section 22 is provided with a first air guide hole 22a, and the gun barrel 1 is provided with a second air guide hole 11 communicated with the first air guide hole 22a.

[0027] It also includes an adjuster 3, the rear section of the adjuster 3 is an adjustment section 31, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap