A clamping mechanism for hexagonal quick-release clamps

A hexagonal and fixture technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve problems such as uncontrollable rope strength, extrusion deformation and irregular molding of firecracker barrels, hindering automatic production of firecrackers, etc., and achieve laborious operation , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

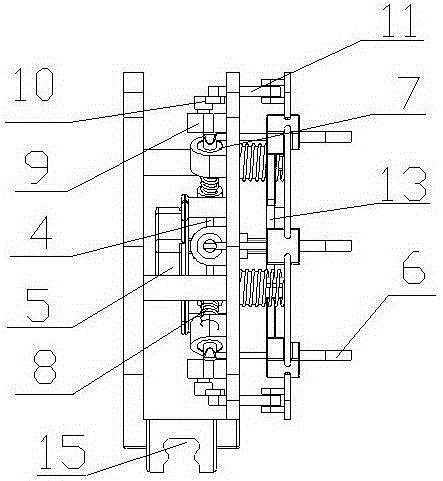

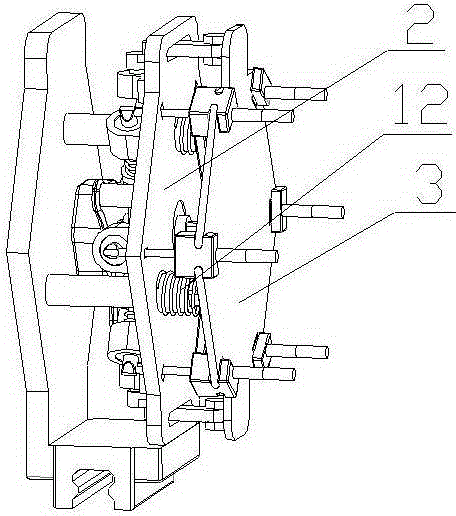

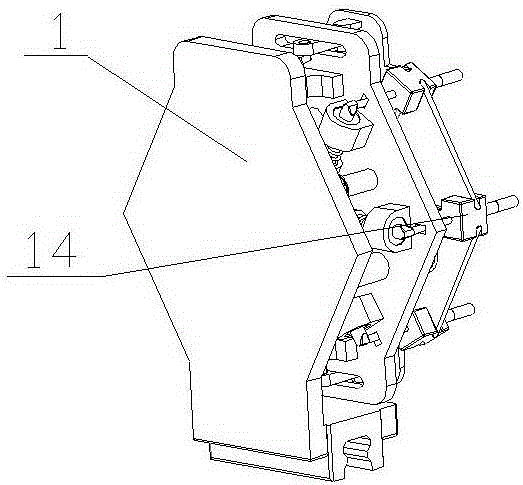

[0023] Such as figure 1 , 2 , 3, a clamping mechanism for a hexagonal quick-release clamp, including a positioning seat 1, a support plate 2 and a separation plate 3; it is characterized in that: the positioning seat 1 is used as a base, and the support The plate 2 and the separating plate 3 are respectively arranged on the positioning seat 1; the positioning seat 1 is arranged on the left side of the supporting plate 2; the separating plate 3 is arranged on the right side of the supporting plate 2; the supporting plate 2 and the The positioning seat 1 is fixed by bolts; the support plate 2 is connected with the separation plate 3;

[0024] The positioning seat 1 is provided with a chute 15, which is an "Ω"-shaped chute;

[0025] The middle position of the support plate 2 is provided with a first cam disc 4; the first cam disc 4 is connected with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com