Special-shaped parallel groove clamp

A type of wire clip and special-shaped technology, applied in the direction of clamping/spring connection, multi-conductor connector, electrical components, etc., can solve the problems of wire joint power, transmission circuit failure, increase in wire clip production cost, etc., to ensure the robustness, overall Good structure and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

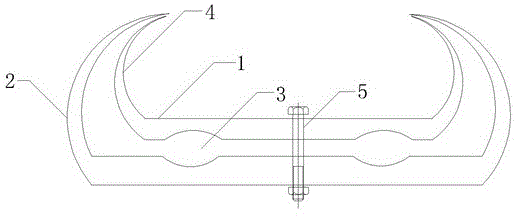

[0015] Such as figure 1 As shown, a special-shaped parallel groove clamp of this embodiment includes an upper pressing part 1 and a lower pressing part 2, and the upper pressing part 1 and the lower pressing part 2 are fixedly connected by bolts 5, and the inner part of the upper pressing part 1 The surface is provided with a concave arc-shaped wire groove, and the upper surface of the lower pressing part 2 is provided with an arc-shaped inner concave wire groove corresponding to the wire groove of the upper pressing part 1, and the two correspond to each other to form a wire clamp for accommodating wires Slot 3. The outer surface of the upper pressing part 1 intersects with the inner surface at the end to form a raised end 4, and the two ends of the lower pressing part 2 also form corresponding curved parts. The inner surface of the crotch of the pressing part 2 is attached to each other, that is, the two can move with each other, and the two are always kept in a sealed stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com