Rack type modular secondary screen cabinet in prefabricated cabin

A technology of secondary screen cabinets and prefabricated cabins, applied in the direction of electrical components, substation/switch layout details, etc., can solve the problems of long construction period, low space utilization rate, long waiting period, etc., shorten the construction period, simplify Wiring construction, reduce the effect of secondary wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Best practice:

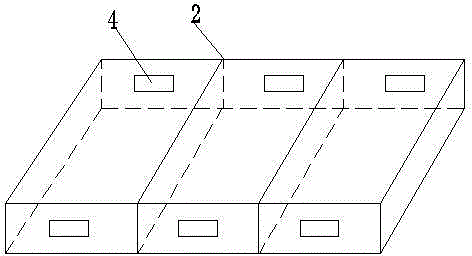

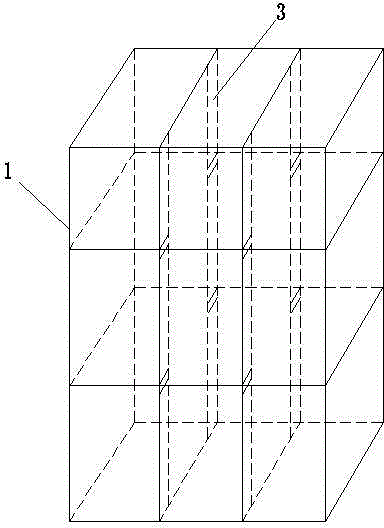

[0021] Refer to attached figure 1 And attached figure 2 , a prefabricated rack-mounted modular secondary screen cabinet in the cabin, including a cabinet body 1 and a screen cabinet base 2. The screen cabinet base 2 is a rectangular frame body made of channel steel and welded as a whole. The screen cabinet base 2 is installed with The cable storage box is provided with a cable inlet and outlet 4 at the front and rear. The bottom of the cabinet 1 should be arranged with two channel steels (above 8#) as the installation base of the cabinet, and then fixedly connected with the channel steel of the screen cabinet base 2 through anchor bolts, so as to be fixedly installed on the screen cabinet base 2. The height of the base of the modular secondary screen cabinet carrying the cabinet is not less than 400mm. The modular secondary screen cabinet should have a detachable auxiliary frame, which can fix the top of the cabinet and protect the outer shell of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com