display device

A display device and display function technology, applied in the fields of instruments, computing, electrical digital data processing, etc., can solve the problems of noise reduction, insufficient noise generation, difficulty in providing high-sensitivity touch sensing technology, etc., to reduce noise, simplify The effect of wiring construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

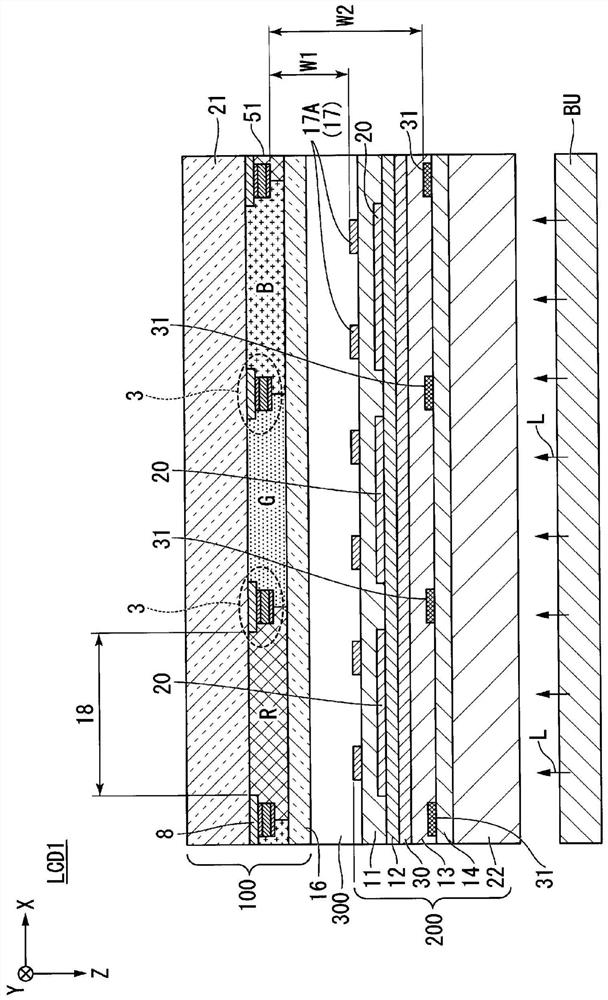

[0321] use Figure 20 to Figure 25 A liquid crystal display device LCD2 of the second embodiment will be described. The same reference numerals are assigned to the same components as in the above-mentioned first embodiment, and description thereof will be omitted or simplified.

[0322] Figure 20 It is a plan view partially showing the array substrate 200 constituting the liquid crystal display device LCD2 according to the second embodiment of the present invention, and is a plan view viewed from the observer side.

[0323] Figure 21 It is a cross-sectional view partially showing the array substrate 200 constituting the liquid crystal display device LCD2 according to the second embodiment of the present invention, along the Figure 20 Sectional view of line D-D' shown.

[0324] Figure 22 It is a plan view partially showing a liquid crystal display device LCD2 according to the second embodiment of the present invention, and is a plan view showing a structure in which a ...

no. 3 Embodiment approach

[0344] use Figure 27 to Figure 29 The liquid crystal display device LCD3 of the third embodiment will be described.

[0345] The same reference numerals are assigned to the same components as in the above-mentioned first embodiment, and description thereof will be omitted or simplified.

[0346] Figure 27 It is a plan view partially showing the array substrate of the liquid crystal display device according to the third embodiment of the present invention. Figure 28 It is a plan view partially showing a display device according to a third embodiment of the present invention, and is a plan view showing a structure in which a display device substrate including color filters and touch sensor wiring is laminated on an array substrate via a liquid crystal layer, viewed from A top view from the side of the observer. Figure 29 It is a cross-sectional view partially showing the array substrate constituting the display device according to the third embodiment of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com