Heat exchange unit and human body part washing device equipped with heat exchange unit

A technology for a heat exchange unit and a main body, which is applied to water supply devices, lighting and heating equipment, water heaters, etc., can solve the problems of increasing the number of parts, increasing the size, and complicating assembly, and achieves a reduction in the number of parts and a small stirring area. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

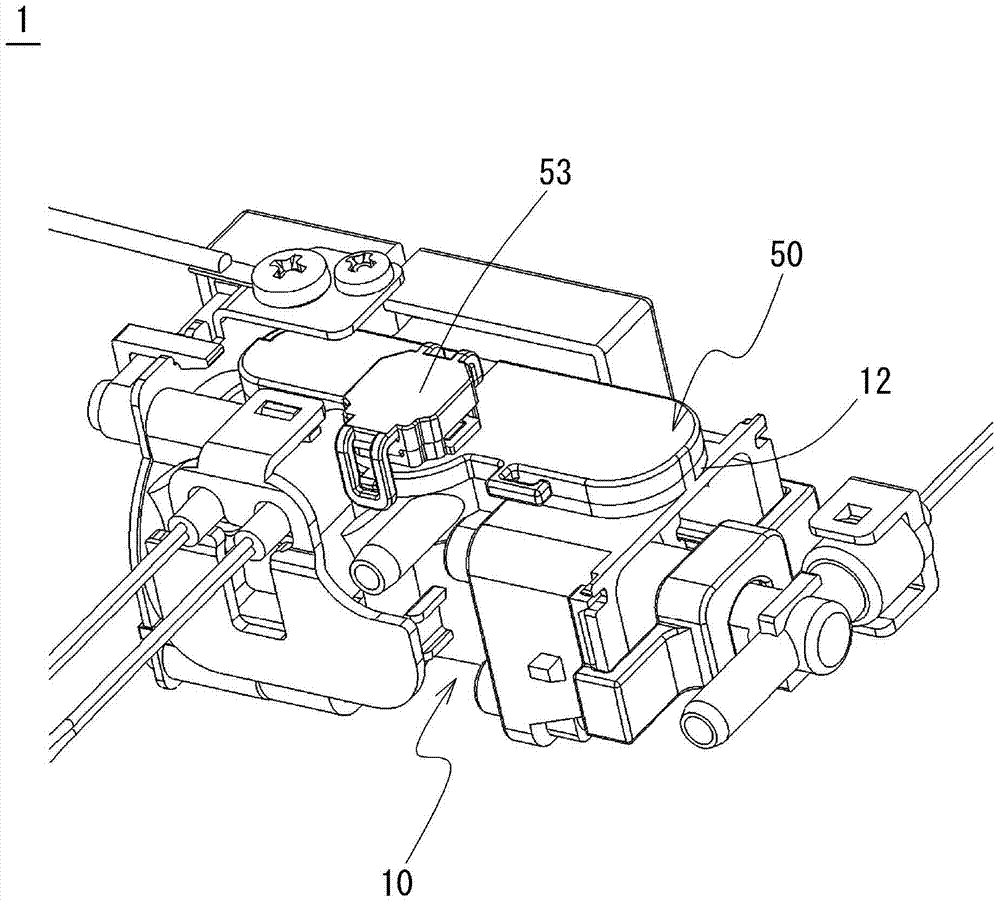

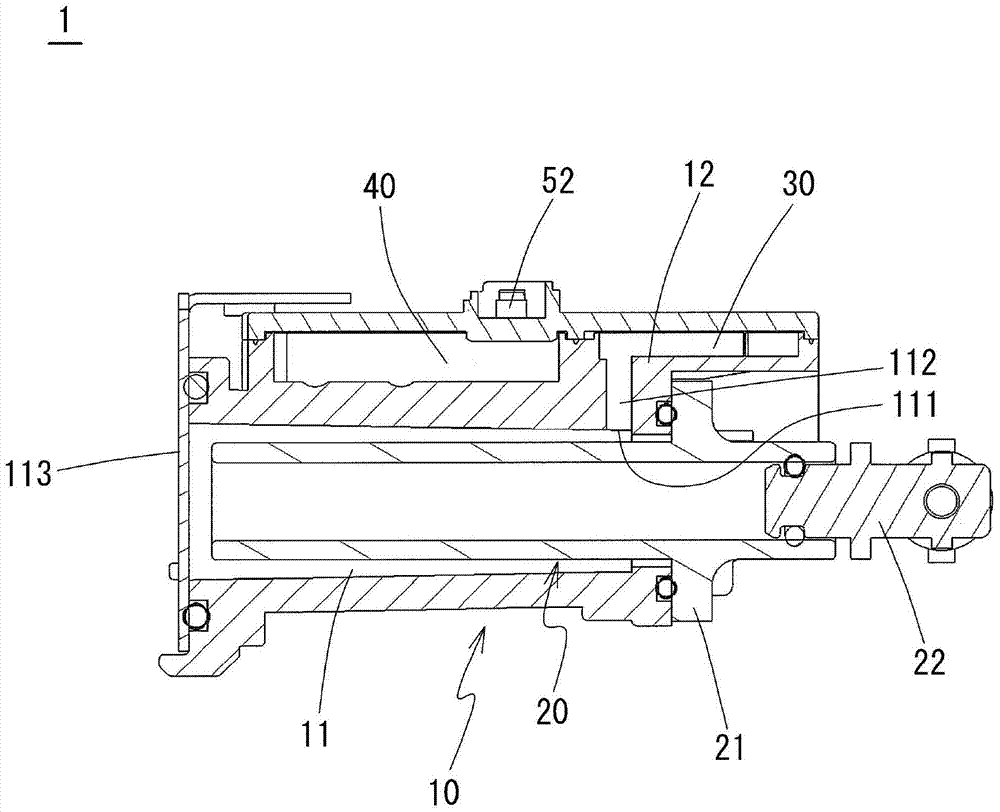

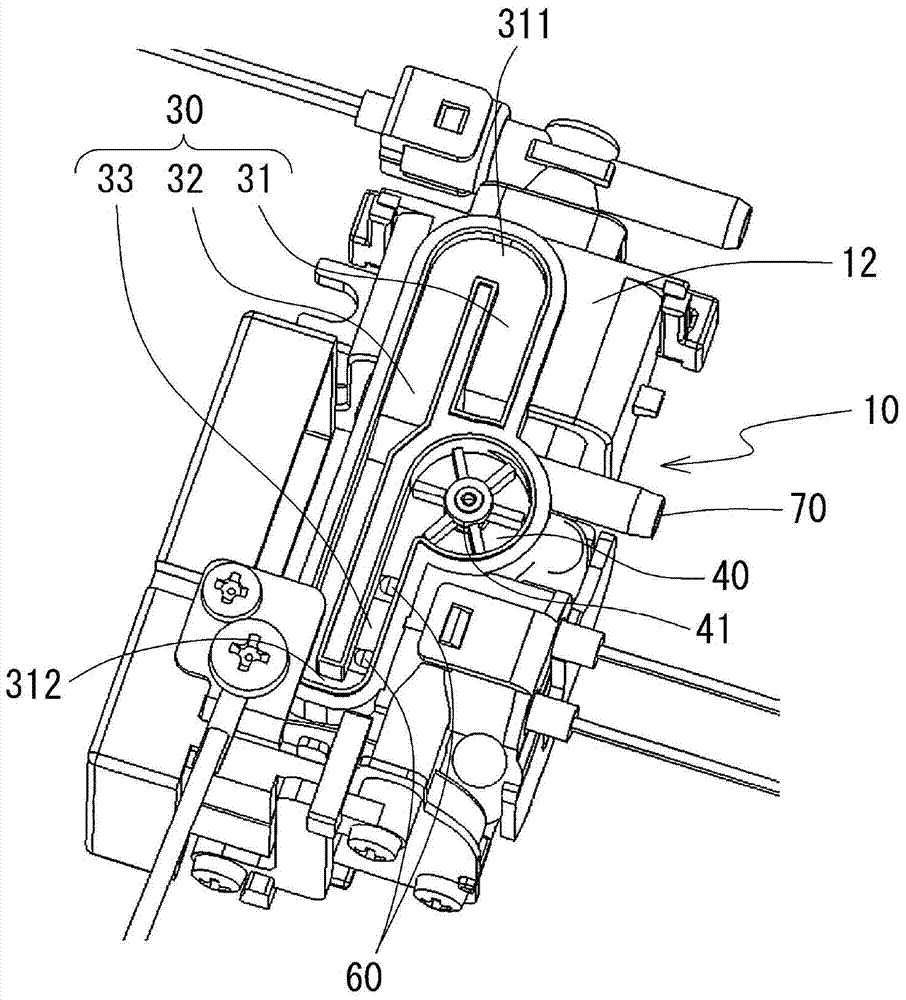

[0052] refer to Figure 1 to Figure 6 And the heat exchange unit 1 which concerns on one Embodiment of this invention is demonstrated in detail. exist figure 1 The heat exchange unit 1 of the present embodiment whose appearance is shown in the figure includes a main body 10 , a heater 20 , an agitation area 30 , a flow detection area 40 , and a cover 50 .

[0053] Such as figure 2 and Figure 4 As shown, the main body part 10 is a member in which a flow space 11 through which fluid passes is formed. The main body portion 10 in this embodiment is integrally formed of a synthetic resin material. The circulation space 11 in this embodiment is a substantially cylindrical space, and water is sent from a water source to this space. A cartridge heater 20 is arranged in the circulation space 11 . On one end side (water source side) of the heater 20 , a flange portion 21 is provided, and the flange portion 21 is in contact with one end surface of the opening of the circulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com