Soft and breathable down garment fabric

A fabric and breathable technology, applied in the field of clothing fabrics, can solve the problems of poor air permeability and comfort, difficult to prevent down-drilling, air permeability and light flexibility, large shrinkage rate, etc. The effect of drilling down and breathability, excellent wind resistance and warmth retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

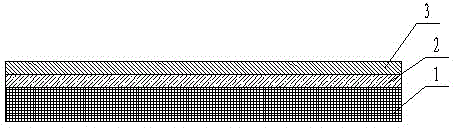

[0020] A soft and breathable down garment fabric, the fabric comprises: a base layer 1, an isolation layer 2 and a coating 3, the lower surface of the isolation layer 2 is bonded to the base layer 1, and the upper surface of the isolation layer 2 is pressed The coating 3 is combined; the base layer 1 is a fabric layer, which is formed by interweaving warp yarns and weft yarns, and the warp yarns are made of cotton fibers and coffee carbon fibers, and the weft yarns are made of recycled polyester The mass percentage of each fiber is: 55% cotton fiber, 28% coffee carbon fiber, 17% recycled polyester fiber, and the linear density of the warp yarn is 15tex, and the linear density of the weft yarn is 12tex , the thickness of the fabric layer is 0.5mm; the isolation layer 2 is a TTU isolation layer, and the thickness of the TTU isolation layer is 15 μm; the coating 3 is a PU coating, and the thickness of the PU coating is 10 μm .

[0021] Wherein, the yarn count density of the fabr...

Embodiment 2

[0024] A soft and breathable down garment fabric, the fabric comprises: a base layer 1, an isolation layer 2 and a coating 3, the lower surface of the isolation layer 2 is bonded to the base layer 1, and the upper surface of the isolation layer 2 is pressed The coating 3 is combined; the base layer 1 is a fabric layer, which is formed by interweaving warp yarns and weft yarns, and the warp yarns are made of cotton fibers and coffee carbon fibers, and the weft yarns are made of recycled polyester The mass percentage of each fiber is: 60% cotton fiber, 25% coffee carbon fiber, 15% recycled polyester fiber, and the linear density of the warp yarn is 15tex, and the linear density of the weft yarn is 12tex , the thickness of the fabric layer is 0.8mm; the isolation layer 2 is a TTU isolation layer, and the thickness of the TTU isolation layer is 10 μm; the coating 3 is a PU coating, and the thickness of the PU coating is 5 μm .

[0025] Wherein, the yarn count density of the fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com