A polishing device and polishing method for the curved surface of a mobile phone panel

A technology for panels and mobile phones, which is applied in the field of polishing devices for processing the arc surface of 2.5D or 3D sapphire mobile phone panels. It can solve the problems of increasing the difficulty of plane polishing, uneven force on the brush, and poor polishing effect, so as to improve plane polishing. Accuracy, avoiding unevenness of the brush, and reducing the difficulty of flat polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

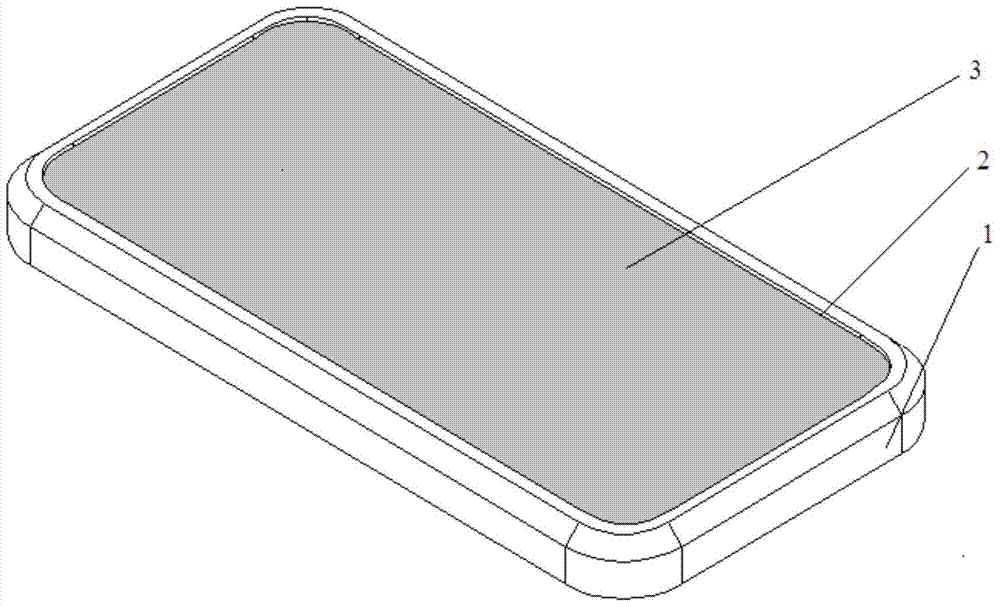

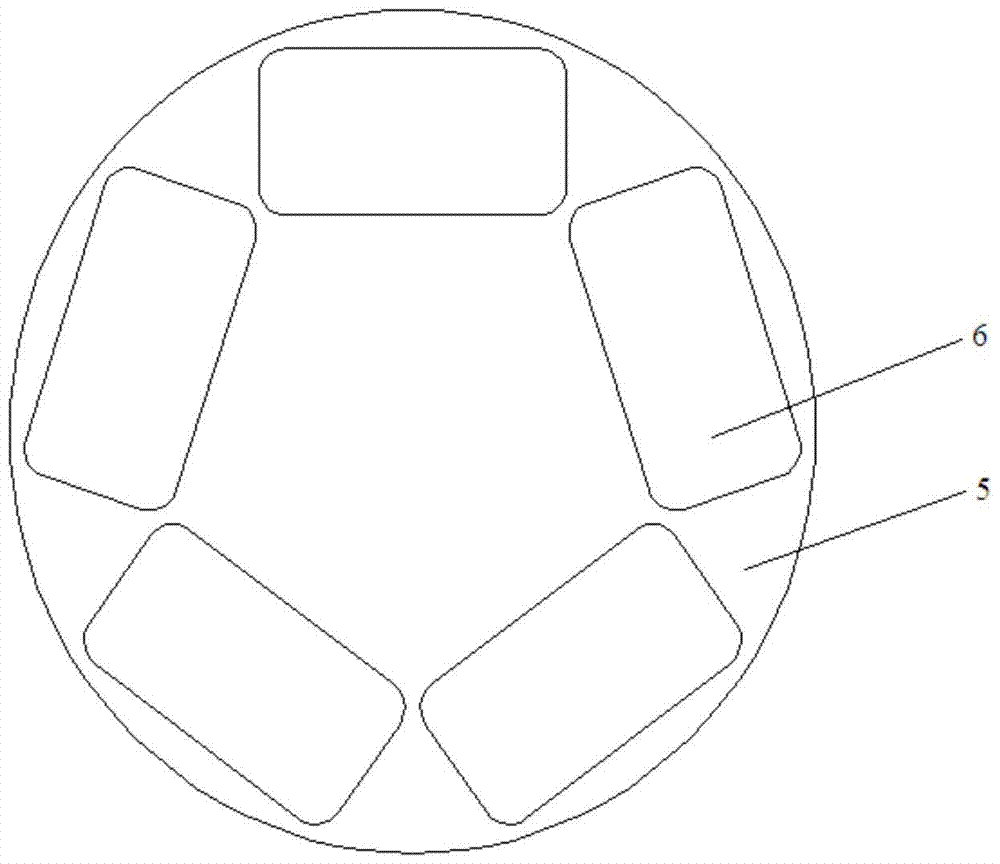

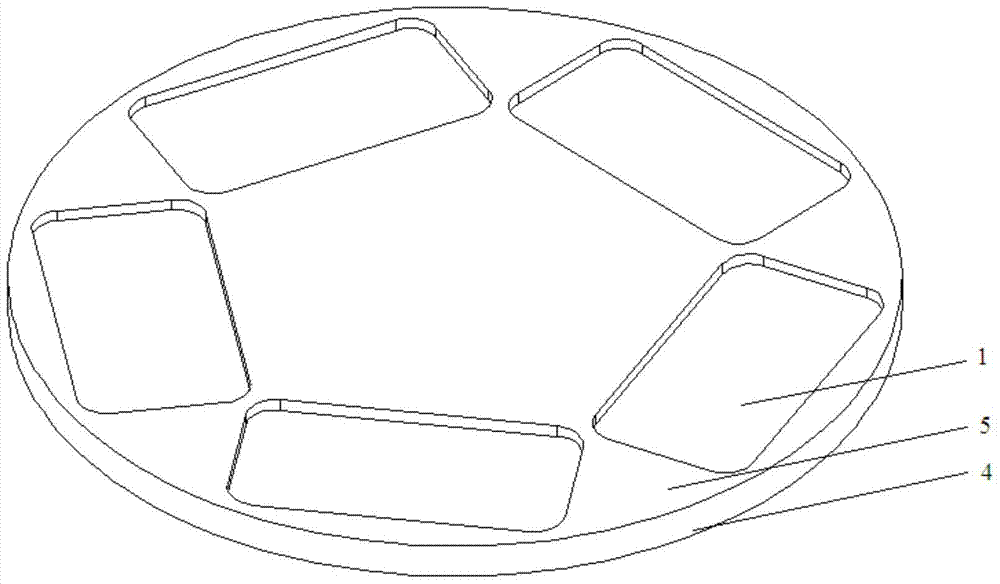

[0023] Arc surface polishing device: as attached Figure 1~3 As shown, in the present embodiment, a curved surface polishing device for mobile phone panels is provided, including a base body 1 and a ceramic disc 4 with a protective cover 5; the base body is provided with sinkers designed correspondingly according to the sample size of the mobile phone panel 2. An adsorption pad 3 fixedly connected to it for absorbing the panel of the mobile phone is set in the sinker; the protective cover is fixedly connected to the ceramic plate, and the protective cover is provided with a cavity 6 for placing the substrate . Those skilled in the art can easily understand that sinkers with different groove depths and / or surface dimensions can be designed according to different cell phone panel sample sizes. When using the curved surface polishing device of the present invention, the mobile phone panel sample is placed in the sink and the curved surface is exposed, and it is polished by a pol...

Embodiment 2

[0028] The arc surface polishing device and the method of using the arc surface polishing device in this embodiment are the same as those in Embodiment 1.

[0029] Choose SiO with a particle size of 80nm 2 The polishing liquid is polished by a SPEEDFAM four-head polishing machine with a 3D polishing pad: the processing parameters are, the polishing liquid ratio: 3L (polishing liquid): 6L (pure water); pressure: 0.32g / cm 2 ; Polishing liquid flow rate: 6L / min; Lower plate speed: 45rpm; Polishing time: 30min.

[0030] According to the process of this embodiment, the sapphire arc surface is processed, and the roughness of the arc surface reaches below 1.5nm. Using this processing technology, not only is there no damage to the plane, but it is also beneficial to the flatness and smoothness of the plane, reducing the difficulty of polishing the plane CMP, and the arc surface After polishing, the plane roughness reaches 0.5-0.8nm.

Embodiment 3

[0032] The arc surface polishing device and the method of using the arc surface polishing device in this embodiment are the same as those in Embodiment 1. In addition, the parameters during the polishing process were set as follows.

[0033] First grind:

[0034] Choose SiO with a particle size of 80nm 2 The polishing liquid is polished by a SPEEDFAM four-head polishing machine with a 3D polishing pad: the processing parameters are, the polishing liquid ratio: 5L (polishing liquid): 5L (pure water); pressure: 0.24g / cm 2 ;Polishing fluid flow rate: 6L / min; Lower plate speed: 45rpm; Polishing time: 60min;

[0035] After polishing, clean the machine table and brush the disc surface;

[0036] Second mill:

[0037] The polishing liquid of the first grinding is recycled, and the newly added polishing liquid 2L (polishing liquid): 2L (pure water), the material of the newly added polishing liquid is the same as that of the first grinding, and the product is polished. The polishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com