Automatic rhinestone ironing and pattern arranging device and automatic rhinestone ironing and pattern arranging method thereof

A drilling row and automatic technology, applied in the field of hot stamping, can solve the problem that non-magnetic rhinestones cannot complete hot stamping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

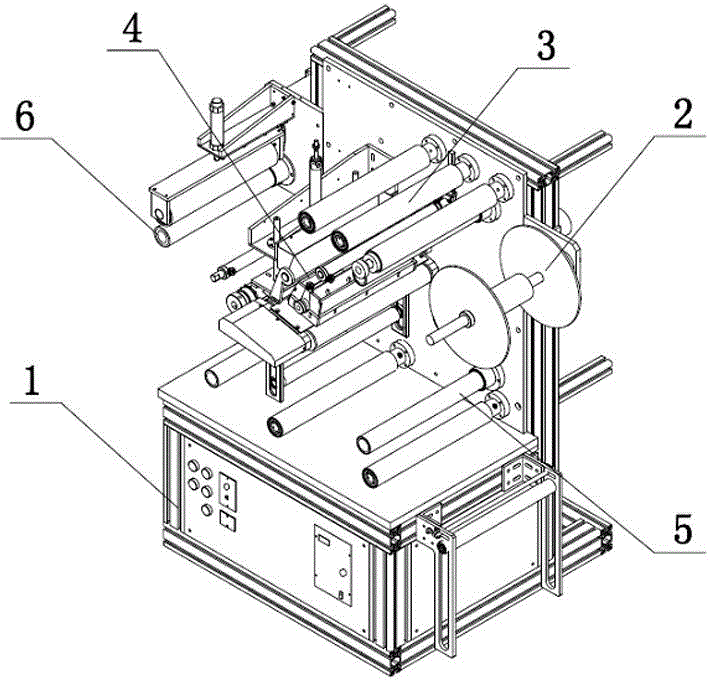

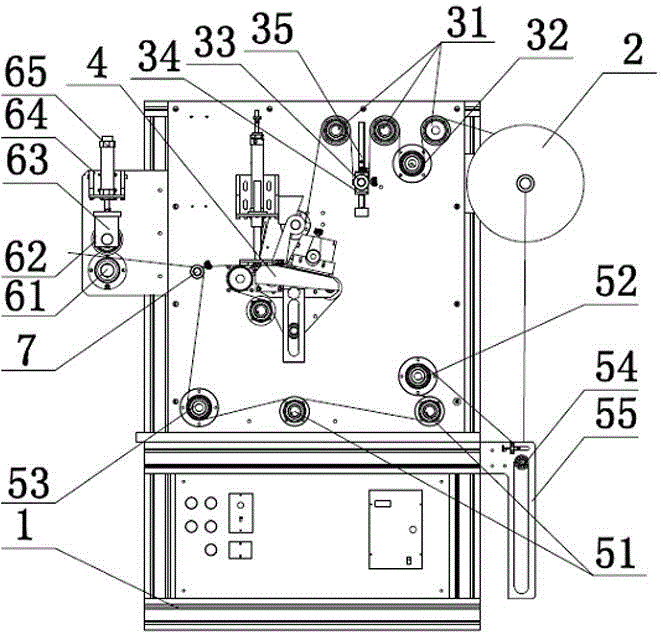

[0036] Example: such as figure 1 As shown, an automatic ironing drill layout device includes a workbench 1 designed according to the vertical worktable layout, the center of the workbench 1 is provided with a brush drill module 4, and one side of the brush drill module 4 is provided with a discharge mechanism 2 , the other side is provided with an output mechanism 6, a set of hot paper conveying rubber rollers 3 is arranged between the discharging mechanism 2 and the brush drill module 4, and a set of substrate conveying rubber rollers 5 is arranged between the output mechanism 6 and the discharging mechanism 2 .

[0037] Such as figure 2 As shown, the discharging mechanism 2 is a sleeve fixed on a certain shaft, and the sleeve is wound with a complex of ironing paper and a substrate. The substrate is conveyed by rubber roller group 5.

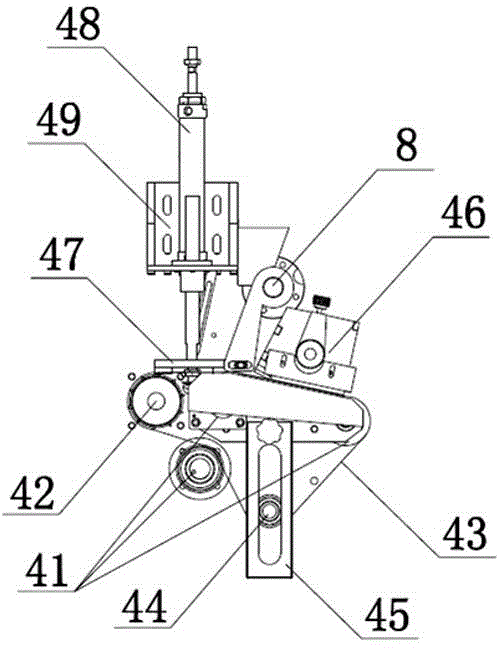

[0038]Ironing paper conveying rubber roller group 3 further comprises an ironing paper driving roller 32, three ironing paper driven roll...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap