An installation device and method for an underwater part of an azimuth thruster

A technology of azimuth thrusters and installation devices, which is applied to ship components, transportation and packaging, ships, etc., can solve problems such as low safety, long installation period, and high labor intensity of constructors, and achieve the difficulty of turning over and construction Easy, Guaranteed Safe Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

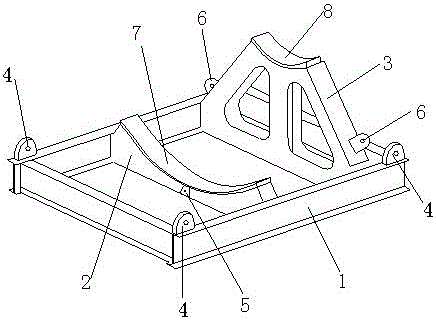

[0032] Such as figure 1 As shown, the installation device for the underwater part of the azimuth thruster in this embodiment includes a steel frame support 1, and the steel frame support 1 is provided with a shroud and a bearing seat for supporting the propeller 9 respectively. The first support seat 2 and the second support seat 3, the contact surface of the first support seat 2 and the shroud is an arc-shaped inclined curved surface, and the contact surface of the second support seat 3 and the bearing seat is an arc-shaped contact surface. The four corners of the steel frame support 1 are respectively provided with installation hanging codes 4, the first support base 2 is provided with a first fixed suspension code 5, and the two sides of the second support base 3 are respectively provided with There is a second fixed hanging code 6. The first support seat 2 and the second support seat 3 ensure that the propeller 9 is supported stably, and the setting of the first support s...

Embodiment 2

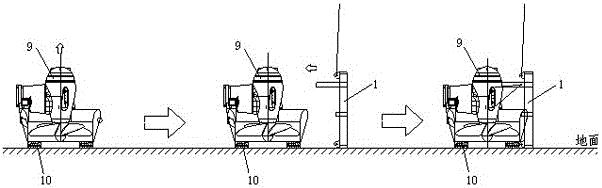

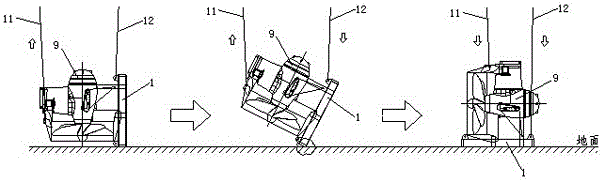

[0036] The method for installing the propeller 9 using the installation device for the underwater part of the azimuth propeller described in this embodiment includes the following steps:

[0037] 1) Design and assemble a steel frame support 1 with the same size as the shroud and bearing seat of the propeller 9, and install hanging codes 4 at the four corners of the steel frame support 1 for hoisting and angle adjustment; The radian size and spacing of the cover and the housing of the bearing seat, the first support seat 2 and the second support seat 3 for supporting the propeller 9 are arranged on the steel frame support 1; the first support seat 2 and the second support seat 3 Lay the first rubber pad 7 and the second rubber pad 8 on the curved curved surface of 3 respectively to complete the production of the installation device;

[0038] 2) Place the installation device completed in step 1) along the vertical direction and close to the propeller 9, and fix and lock the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com