A liquid crystal glass packaging box and moisture-proof packaging structure

A technology of liquid crystal glass and packaging structure, applied in the field of packaging, can solve the problems of water mist and even water droplets, and achieve good moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

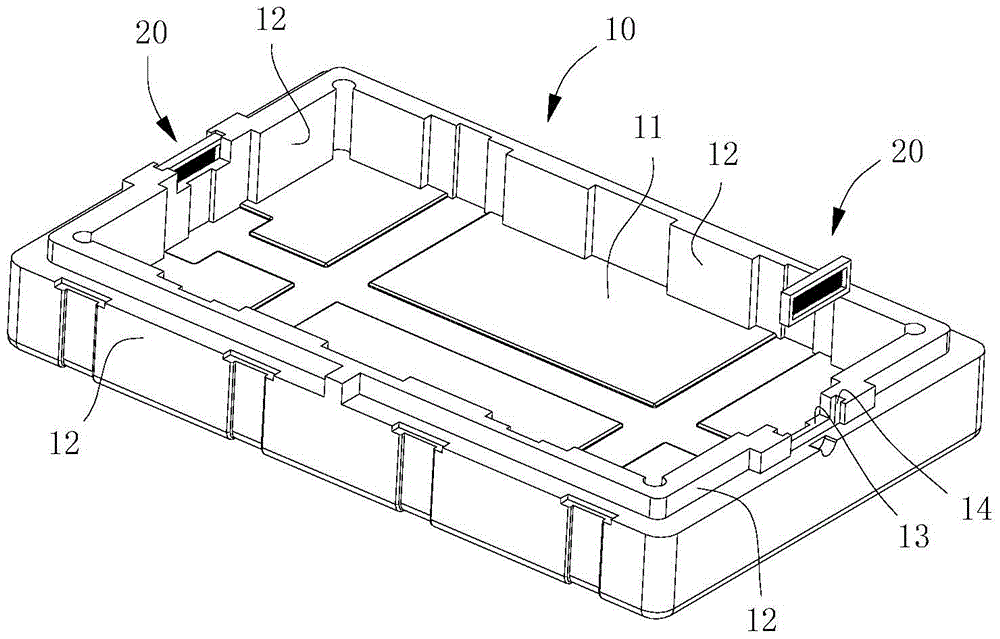

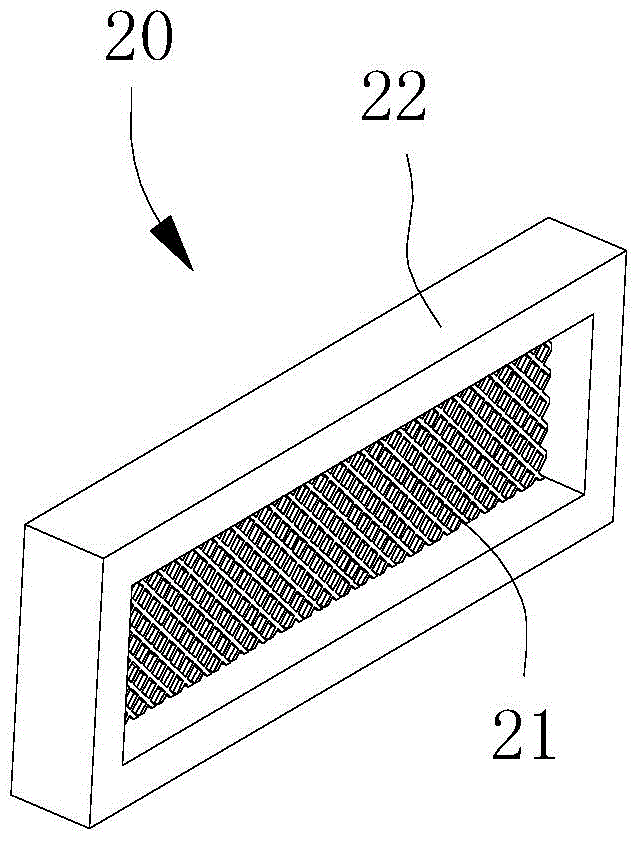

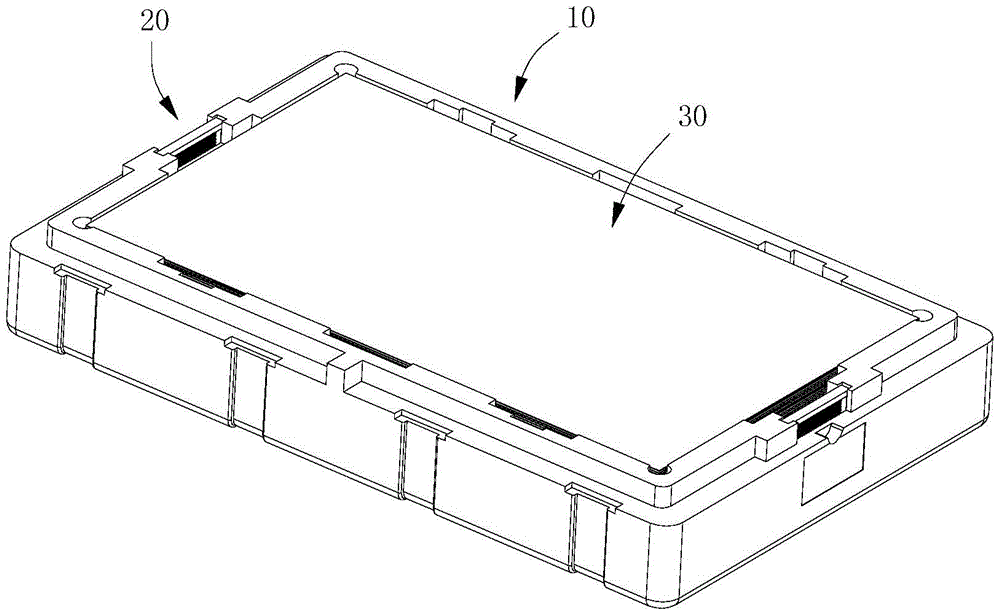

[0025] see figure 1 , this liquid crystal glass packaging box includes a box body 10, and the box body 10 includes a bottom plate 11 and side walls 12 integrally connected around the bottom plate. The purpose of ventilation inside and outside the box body 10 is provided with a filter screen assembly 20 on the box body 10 . The combination of the filter screen assembly 20 and the box body 10 is shown in the figure, a gap 13 is provided on the side wall 12 of the box body 10, slots 14 are provided on both sides of the side wall gap 13, and the filter screen assembly 20 Inserted in the slot 14; the filter screen assembly 20 includes an outer frame 21 and a filter screen 22 fixedly connected to the outer frame 21, the inside and outside of the box body 10 are connected through the filter screen 22 to achieve the purpose of ventilation, and at the same time in order to prevent large Particle foreign matter, such as dust, pollen, etc., enters the box body 10 and contaminates the li...

Embodiment 2

[0027] like Figure 4 As shown, this embodiment is different from Embodiment 1, and a filter screen assembly 20 is also provided on the bottom plate 11 of the box body 10, and a counterbore 15 may be provided on the bottom plate 10, and a through hole 16 is provided in the counterbore 15 , and then the filter screen assembly 20 is embedded in the counterbore 15, and the upper surface of the filter screen assembly 20 is flat with the bottom surface of the bottom plate 11 of the box body. The specification of the screen assembly 20 can be the same as that of the screen assembly 20 on the side wall 12 and can be interchanged.

Embodiment 3

[0029] Considering that with the continuous increase of cost pressure, the number of pieces in the package has been increasing to offset the reduction of the packaging cost of a single piece of liquid crystal glass. At present, the industry is constantly trying to use low-density and low-weight packaging boxes. The former will lead to a continuous increase in the weight of a single package, and the latter will lead to a decrease in the rigidity of the packaging box. Overall, the box has insufficient compressive strength and cannot withstand multiple layers. Stacked situation. In order to solve this problem, the industry attempts to put rigid components into the box body to improve the load-bearing and compression resistance of the box body. This embodiment combines this rigid component with the filter screen assembly provided by the present invention. see Figure 5 , Image 6 , On the side wall 12 of the box body 10, there is a hole 17 through the bottom plate, and the filte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap