Automatic ironing line for down jacket

A technology for ironing lines and down jackets, applied in the field of automatic ironing lines for down jackets, can solve the problems of troublesome control of down jackets, low water supply efficiency of down jacket manufacturers or dry cleaners, etc., and achieves reduction of ironing costs, convenient maintenance, and wide practical range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

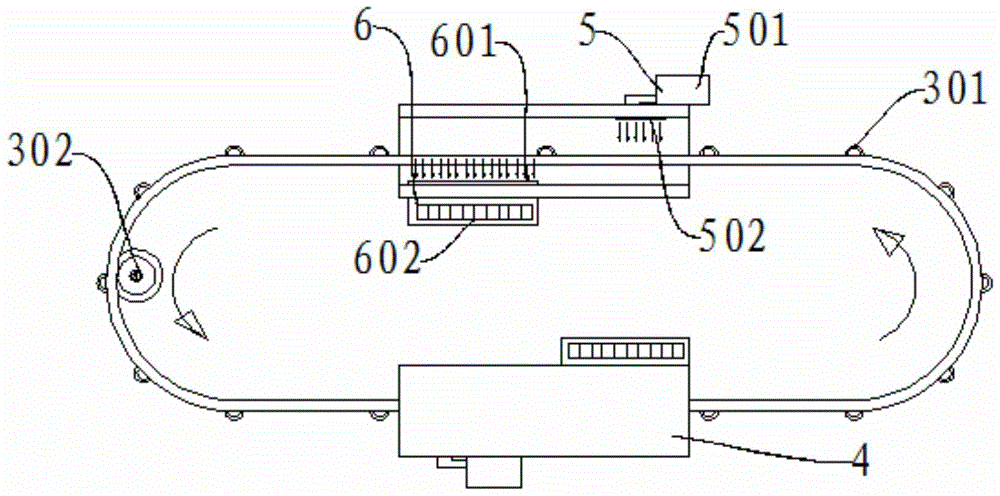

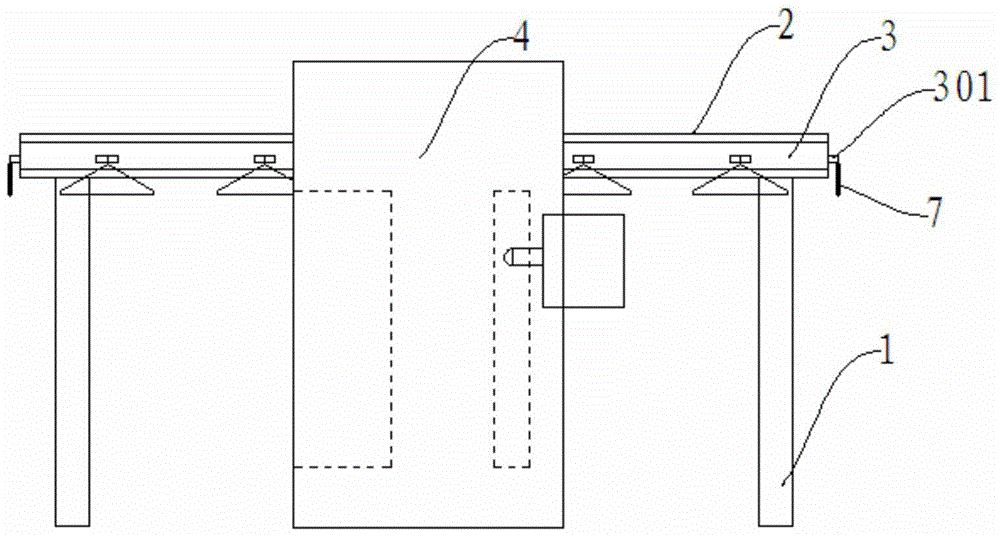

[0015] Referring to the accompanying drawings, an automatic ironing line for down jackets includes a leg 1 and a crossbeam 2 above the mounting leg. The crossbeam 2 forms a circular loop, and a sliding module 3 is provided on the side of the crossbeam 2. The sliding module 3 is connected with the motor 302 installed on the leg 1, the sliding module 3 is provided with several hooks 301, and the automatic ironing line is also provided with several ironing chambers 4, the The crossbeam 2 penetrates into the ironing room 4, and the steam injection device 5 and the air suction device 6 are provided on the ironing room 4; the steam injection device 5 includes a spraying head 502 installed up and down and a The steam generating device 501 outside the ironing room; the air suction device 6 includes a suction plate 601 located in the ironing room and a suction fan 602 located outside the ironing room; the hook 301 is equipped with a clothes hanger 7, and The clothes hanger hook is vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com