steam ironing device

A steam and ironing technology is applied in the field of ironing to achieve the effects of prolonging heating time, improving efficiency and improving ironing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

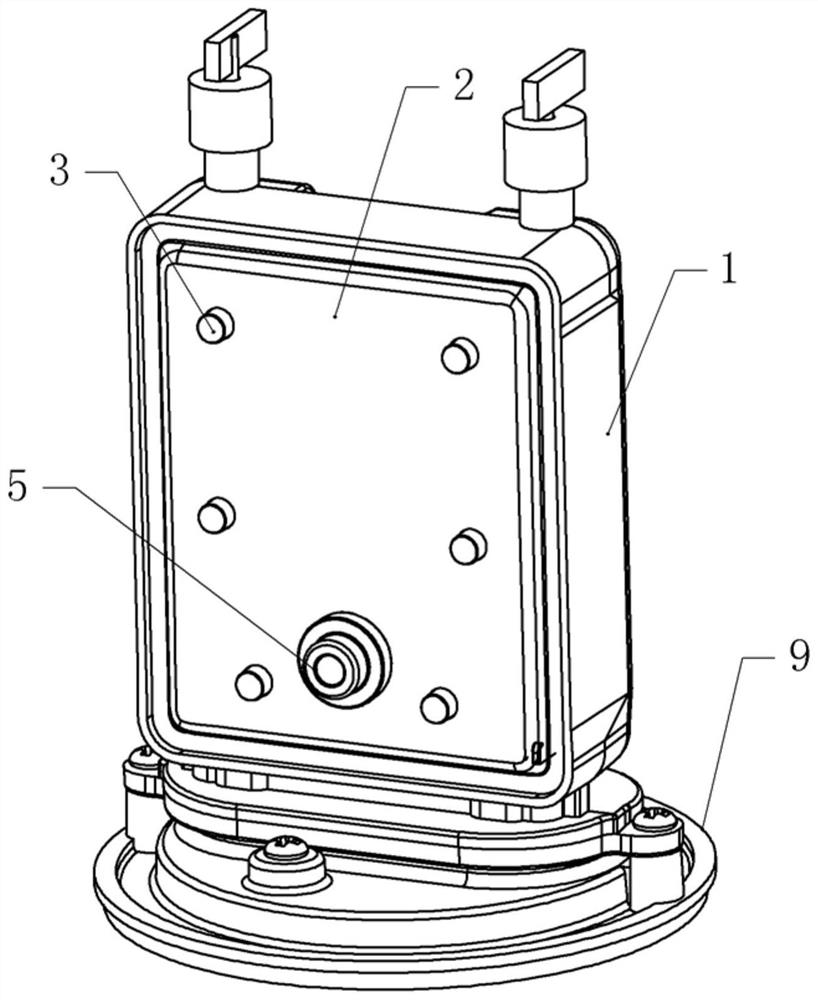

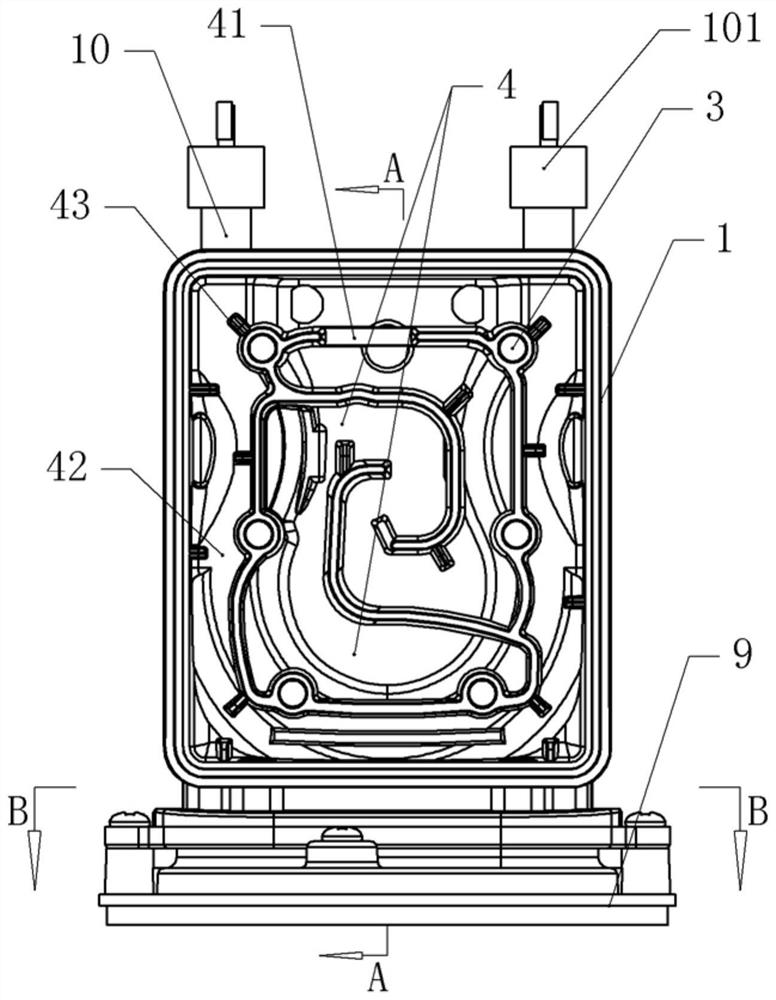

[0043] Basic as attached figure 1 And attached figure 2 As shown, an ironing steam device includes a heating element 1 combined with an attached Figure 4 And attached Figure 5 As shown, the heating element 1 is embedded with heating components in the heating element 1. In this embodiment, the heating element is an electric heating tube 10. In this embodiment, the electric heating tube 10 is U-shaped, and the outer wall of the right end of the electric heating tube 10 is sleeved and fixed. The silicone sleeve 101, the silicone sleeve 101 is used to protect the pins of the electric heating tube 10, the model of the electric heating tube 10 in this embodiment is: M16, and the electric heating tube 10 is electrically connected to a power source through an electric wire.

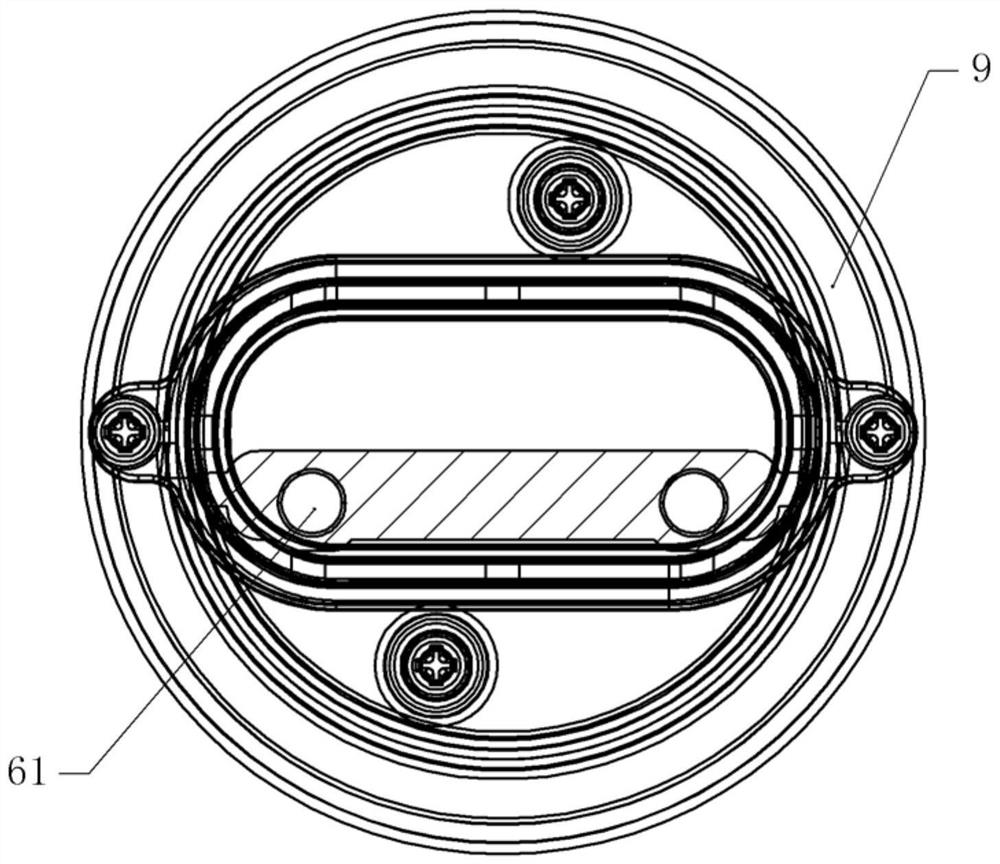

[0044] The heating body 1 is press-molded with a steam cavity, and the steam cavity is located above the electric heating tube 10, combined with the attached figure 2 As shown, in this embodiment, the evap...

Embodiment 2

[0052] The difference between embodiment two and embodiment one is that, as attached Figure 7 And attached Figure 8 As shown, at least two scrapers 71 are arranged on the steam panel 7 , and the longitudinal section of the scrapers 71 is arc-shaped. In this embodiment, a controller is arranged between the two scrapers 71 .

[0053] Specific: as attached Figure 9 As shown, the steam panel 7 is provided with a rotating port, and the scraper 71 is located in the rotating port. The scraper 71 is hinged to the steam panel 7 through a torsion spring. , the right side of the scraper 71 seals the cavity 6 . The upper surface of the scraper 71 is bonded with an adhesive part, the adhesive part is a Velcro (not shown in the figure) in the present embodiment, and the sealing sheet 72 is fixed by fastening bolts in the rotating port. In the present embodiment, the sealing sheet 72 is made of durable Made of high temperature rubber. The controller includes a control shaft 86 fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com