Reciprocating compressor

A compressor and reciprocating technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, electromechanical devices, etc., can solve the problems of supplying gas refrigerant, increasing compression loss, and increasing refrigerant amount, so as to improve the performance of the compressor and reduce the The effect of specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

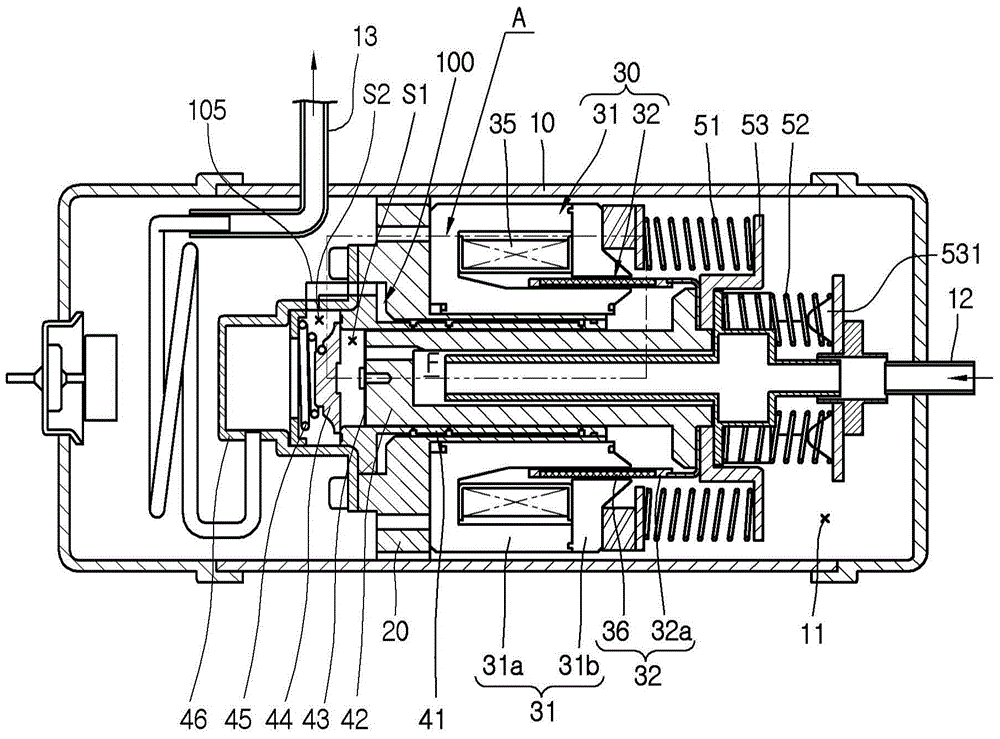

[0045] Hereinafter, the reciprocating compressor of the present invention will be described in detail based on an embodiment shown in the drawings.

[0046] image 3 is a longitudinal sectional view showing the reciprocating compressor of the present invention.

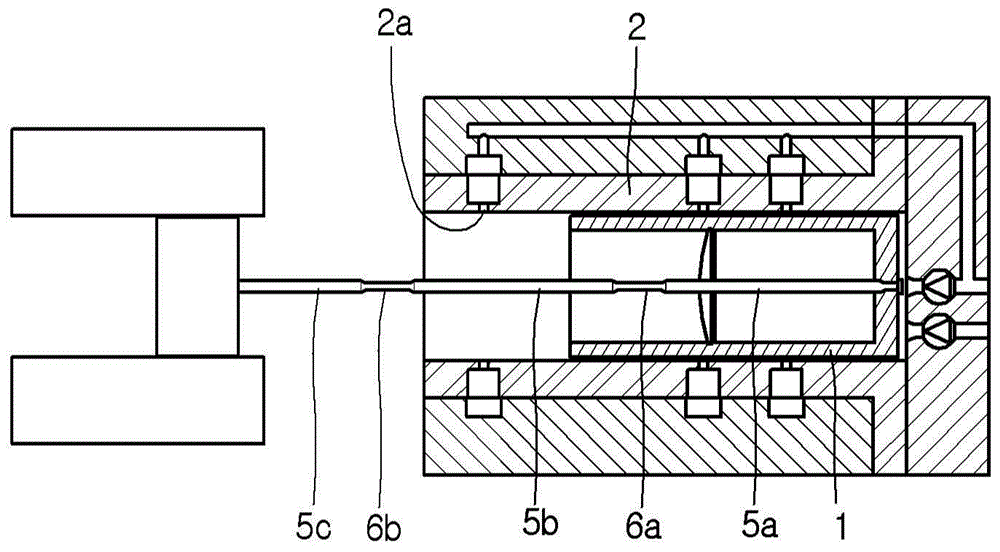

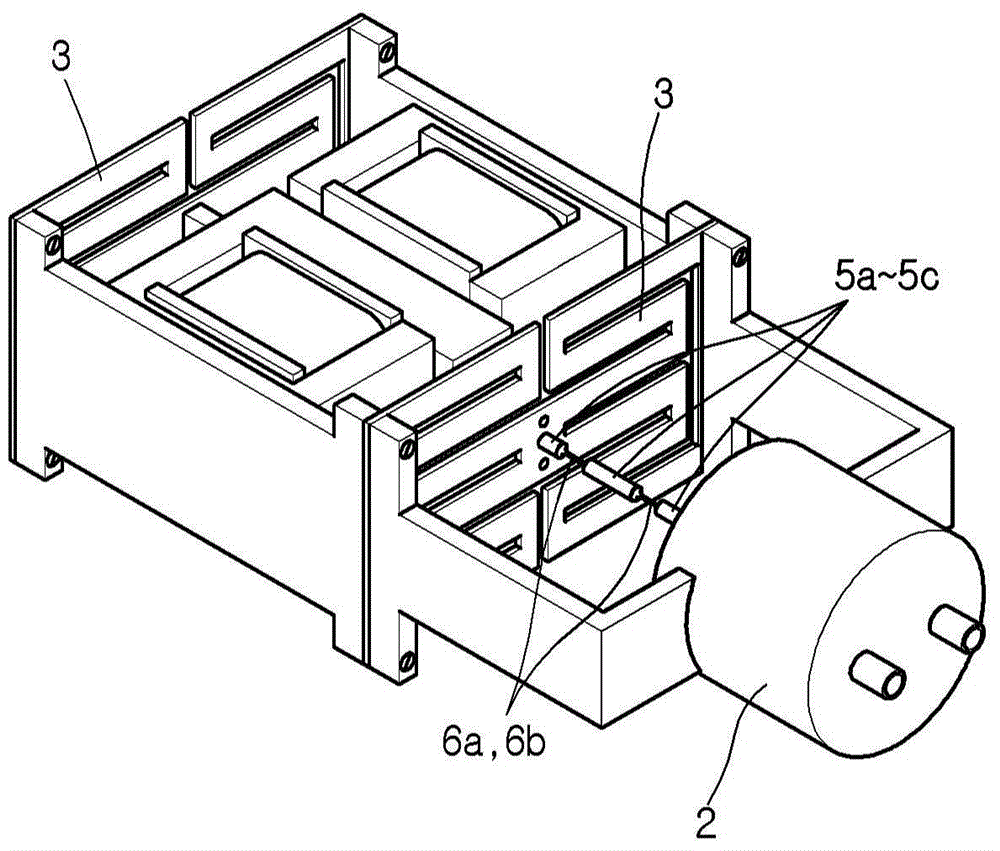

[0047] refer to image 3 , in the reciprocating compressor of the embodiment of the present invention, the internal space of the casing 10 can be connected to the suction pipe 12 , and the discharge space S2 of the discharge cover 46 described later can be connected to the discharge pipe 13 . The inner space 11 of the casing 10 is provided with a frame 20, on which the stator 31 and the cylinder 41 of the reciprocating motor 30 are fixed, and the piston 42 combined with the mover 32 of the reciprocating motor 30 is inserted in the cylinder 41, so that The piston 42 reciprocates in the cylinder 41 , and resonant springs 51 and 52 for inducing the resonant motion of the piston 42 can be respectively provided on both s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com