Refrigerating system based on automobile engine exhaust

A refrigeration system and engine technology, applied in the direction of machines/engines, steam engine devices, steam applications, etc., can solve the problems of only 35% to 40% of the effective power of the engine, insufficient use of fuel heat energy, strong exhaust pressure of automobiles, etc., to achieve The effect of high saturation pressure, low toxicity, and large latent heat of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

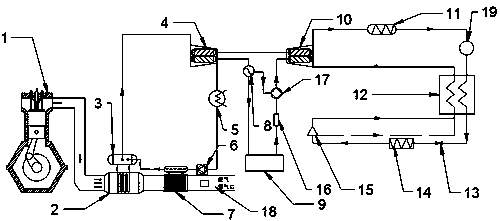

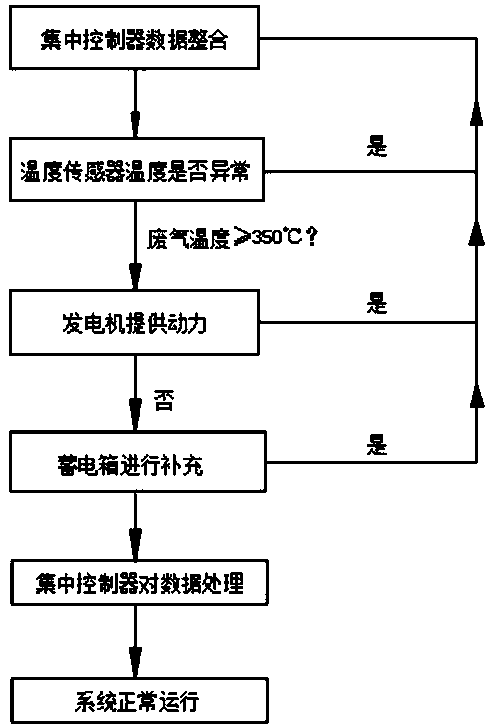

[0009] A refrigeration system based on automobile engine exhaust gas works as follows:

[0010] 1. The principle of organic Rankine cycle power generation of engine exhaust gas

[0011] Main process: The organic Rankine cycle system is a process of converting waste heat into electric energy and kinetic energy. Its working principle is to use the exhaust gas exhausted by the crank linkage mechanism of the engine 1 to flow through the evaporator 2 to heat the organic working medium R134a, so that The organic working medium reaches saturation and enters the steam drum 3, enters the expander 4 to do work, part of it drives the compressor unit for refrigeration, and the other part passes through the generator 8 to generate electricity. When the temperature of the exhaust gas is low, it can be directly driven by the motor to compress 10, when the compressor 10. During normal operation, the generator can generate power to the storage box 9 for energy storage. When the engine 1 stops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com