An engine waste heat recovery and utilization system using organic working medium as coolant

A waste heat recovery and engine technology, which is applied in the direction of machines/engines, engine components, combustion engines, etc., can solve the problems of low overall performance of the refrigeration system, low engine coolant temperature, and difficulty in miniaturization of the unit to reach saturation pressure large, low evaporation temperature, and large latent heat of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

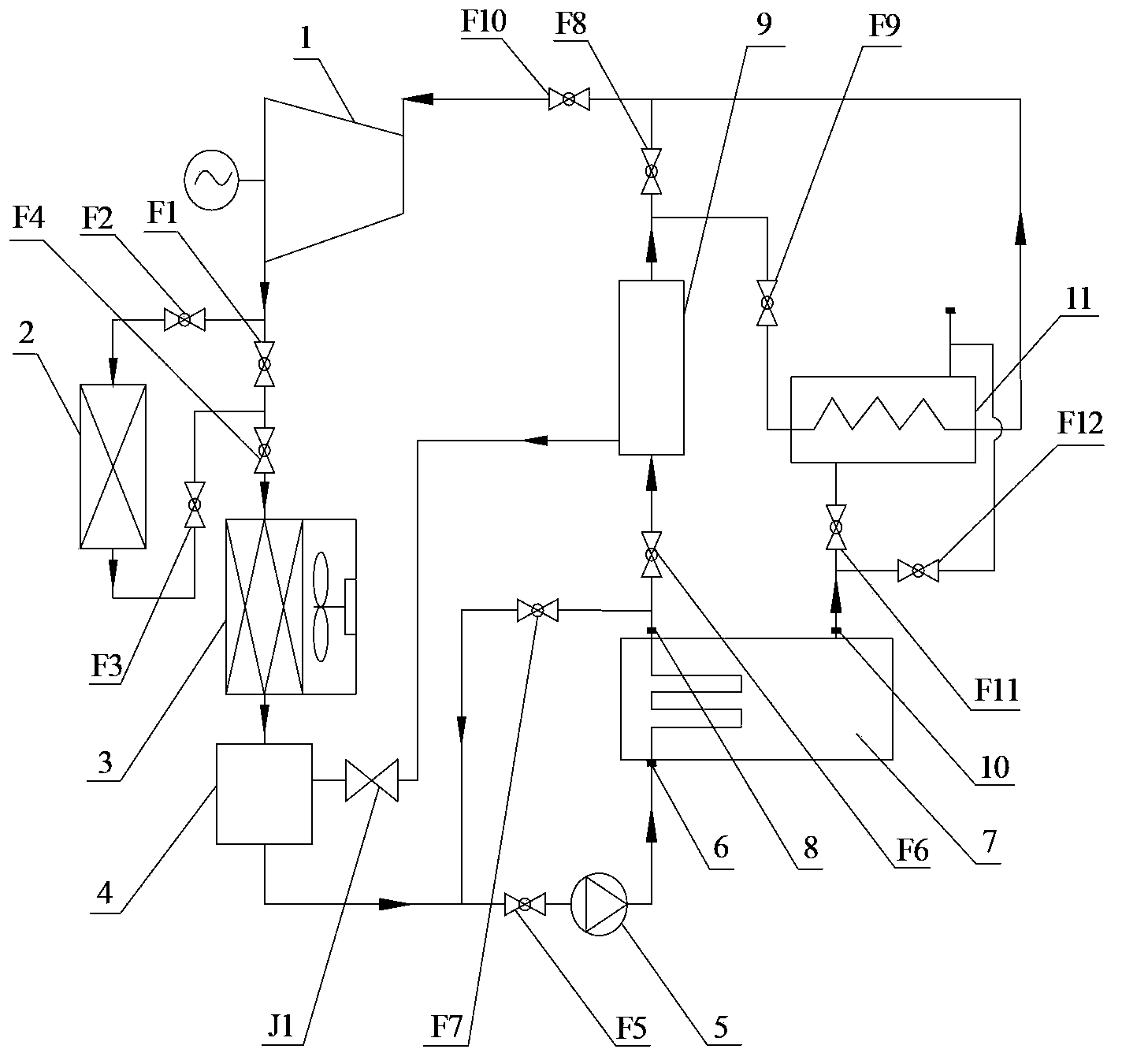

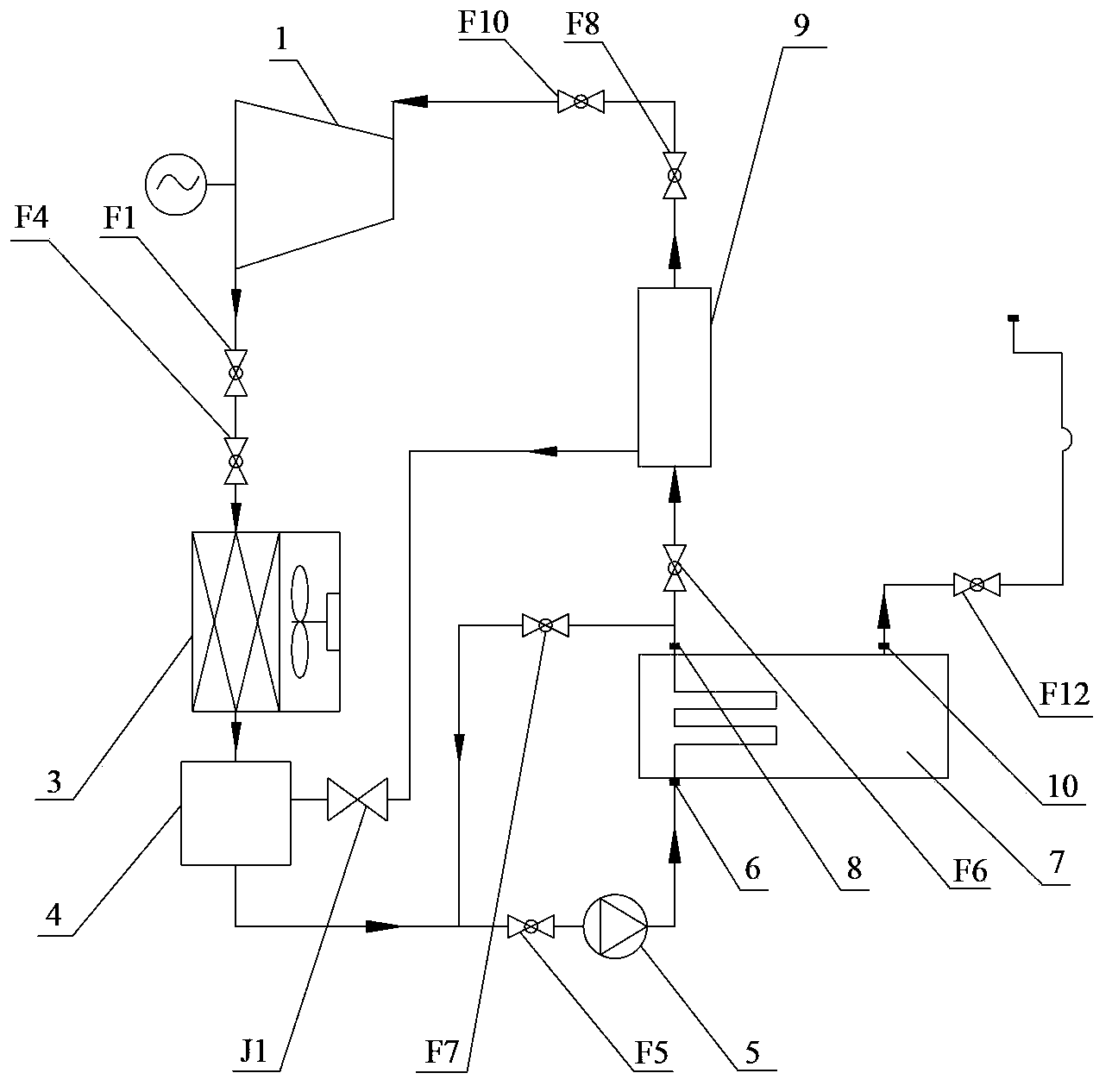

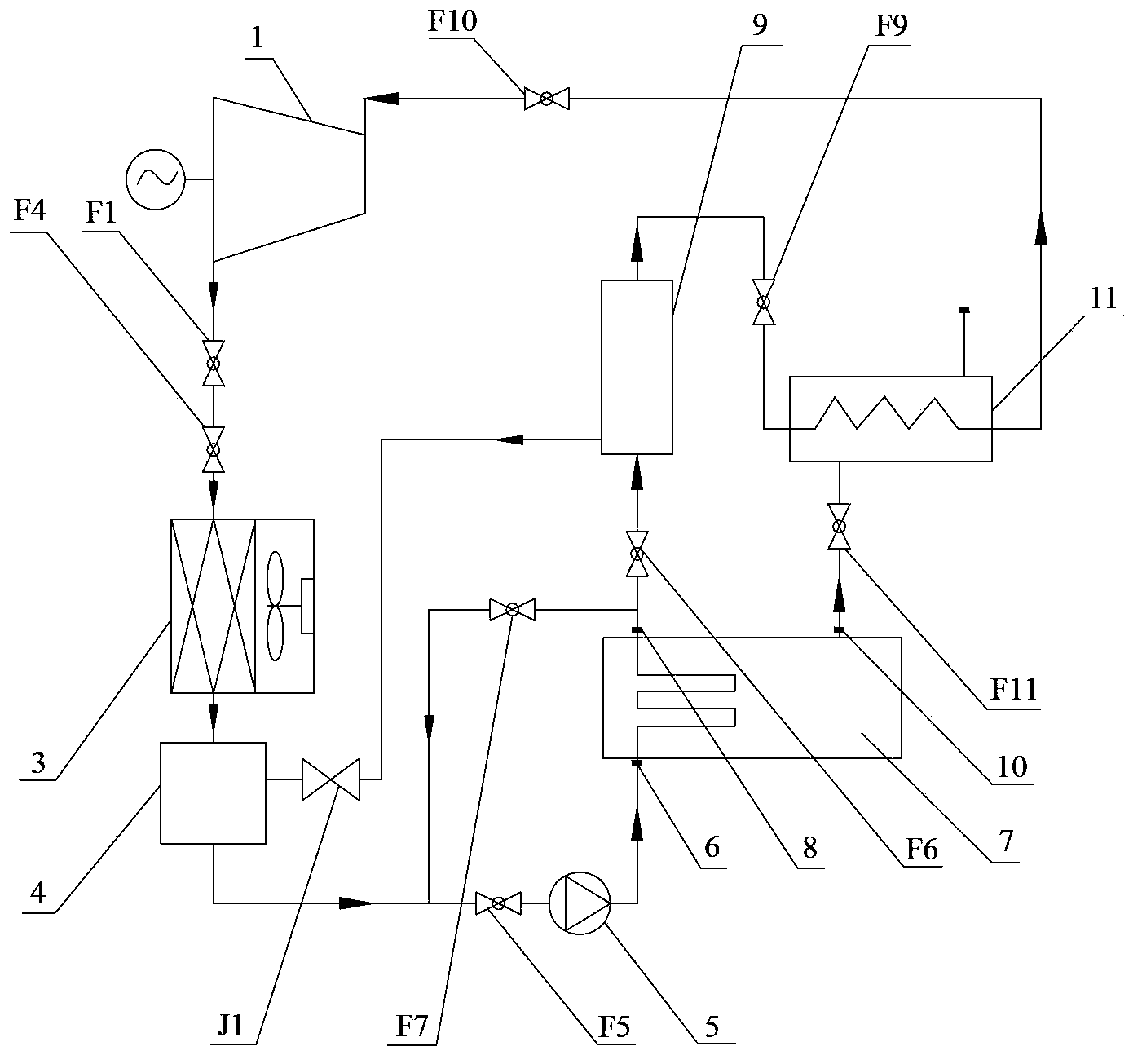

[0021] Such as figure 1 As shown, the engine waste heat recovery and utilization system in which the organic working medium of the present invention is a coolant is connected with the engine 7, the engine internal circulating coolant heat transfer inlet 6, the circulating coolant heat transfer outlet 8, the high-temperature exhaust gas outlet 10 of the engine, the vehicle-mounted The heater 2 is connected, including a turbine 1, an air-cooled condenser 3, a liquid storage tank 4, a coolant circulation pump 5, a flash evaporator 9, a throttle valve J1, an engine exhaust gas waste heat recovery device 11 and the first to twelfth electromagnetic Valves F1-F12; wherein, there are heat exchange tubes in the air-cooled condenser 3, the engine 7, the vehicle heater 2, the flash evaporator 9, and the engine exhaust heat recovery device 11;

[0022] The power output shaft of the turbine 1 is connected to the power transmission system, which can drive the car (ship) air-conditioning com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com