Pipe Connector

A technology of connectors and pipe fittings, applied in the direction of adjustable connections, pipes/pipe joints/pipe fittings, passing components, etc., can solve the problems of low cutting precision, easy rupture of silicone sealing rings, poor applicability of pipe fittings and connectors, etc. Achieving the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

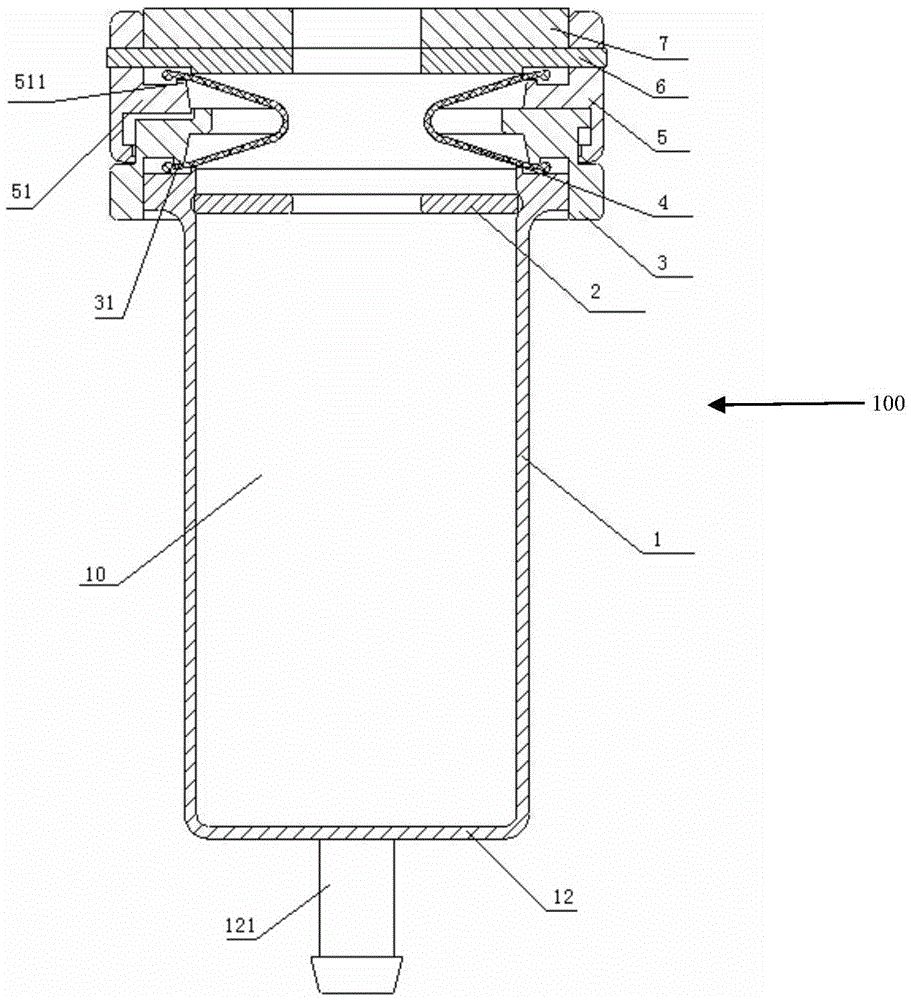

[0024] The specific implementation manner of the pipe fitting connector 100 of the present invention will be described in detail below with reference to the accompanying drawings.

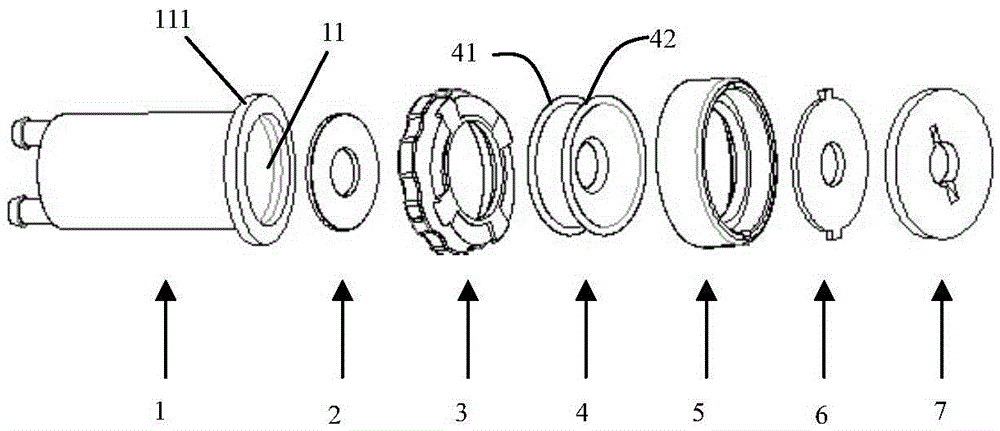

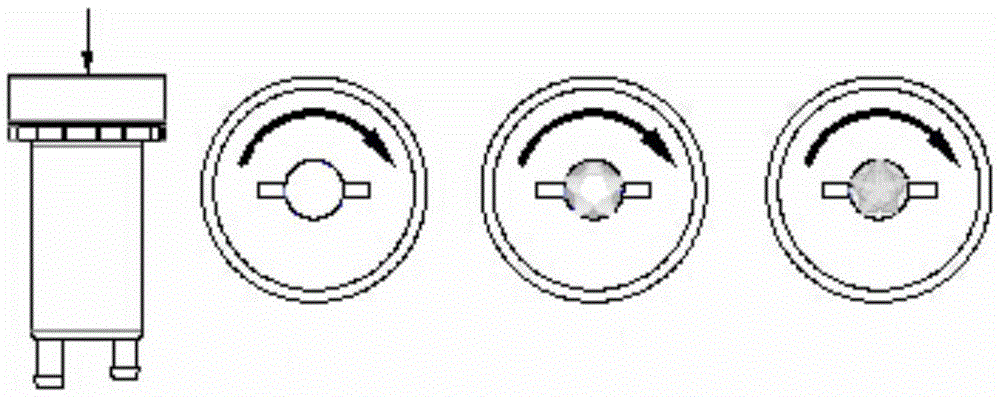

[0025] Please refer to figure 1 with figure 2 , The pipe connector 100 of the present invention includes a main body 1 , a gasket 2 , a fixing part 3 , a sealing part 4 , a rotating part 5 , a pressure plate 6 and a sealing piece 7 . The sealing member 4 is made of flexible material and has an hourglass shape, which includes a first edge portion 41 , a second edge portion 42 and a sealing portion between the first edge portion 41 and the second edge portion 42 . The thickness of the first edge portion 41 and the second edge portion 42 is greater than that of other parts of the sealing member 4 .

[0026] The main body 1 has a containing space 10 for containing the liquid to be transported. In this embodiment, the main body 1 has a first opening 11 at one end and a back cover 12 at the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com