A kind of backlight source, display panel and display device

A technology of backlight and light guide plate, which is applied in the field of display panels, display devices, and backlight. It can solve problems such as limited edge size, poor viewing effect, and impact, and achieve the effects of eliminating shadows, improving display effects, and improving backlight effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

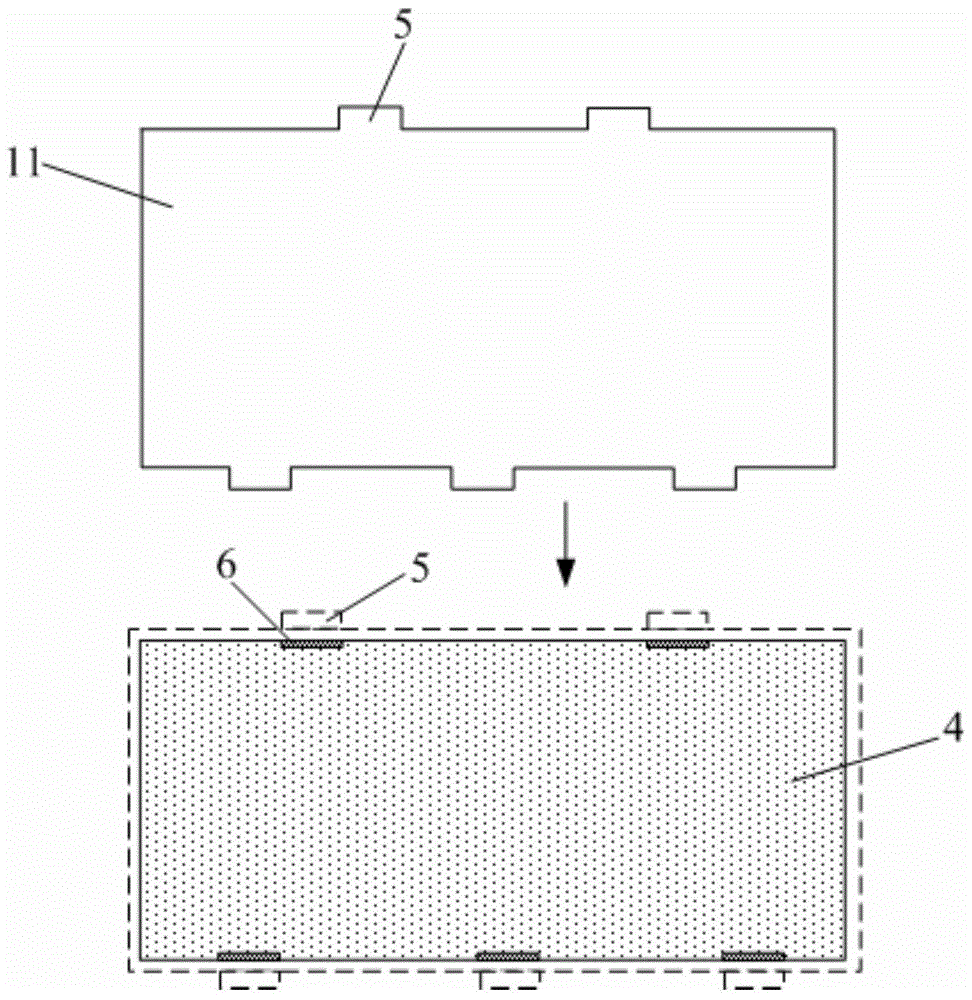

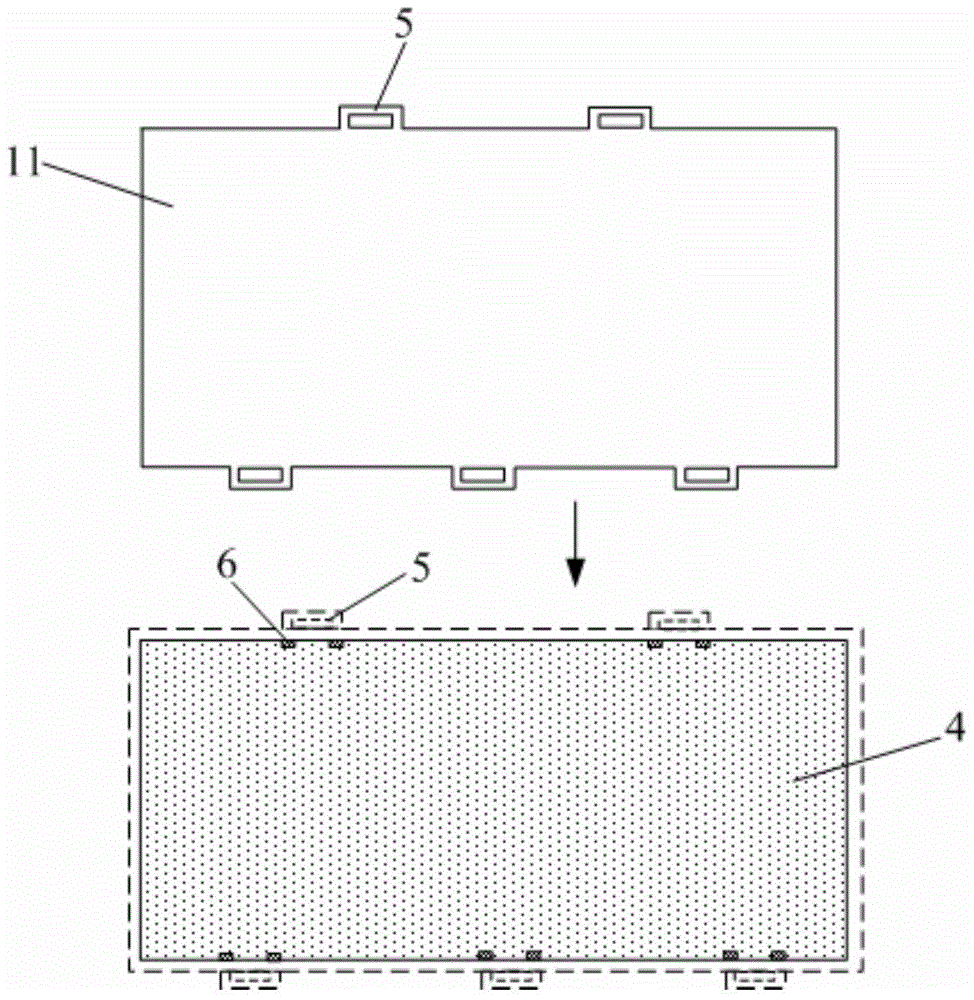

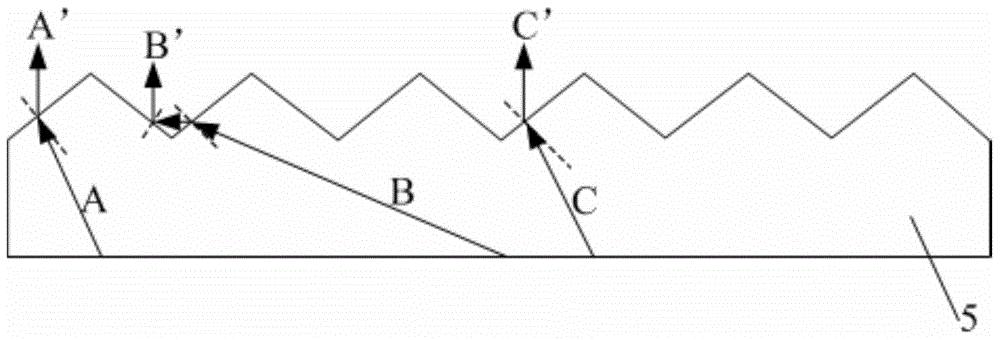

Embodiment 1

[0032] This embodiment provides a backlight, such as Figure 4 and Figure 5 As shown, it includes the light guide plate and the film material group 1 arranged above the light guide plate. The light emitted by the backlight passes through the light guide plate and the film material group 1 in sequence and then is emitted. The partial edge of the film material group 1 extends outward to form a fixed structure 2 The film material set 1 includes a prism sheet 11, and a diffusion layer 3 is provided on the light exit surface of the fixed structure 2 of the prism sheet 11, and the diffusion layer 3 is used to make the light emitted from the light exit surface of the fixed structure 2 uniform.

[0033] Wherein, the fixing structure 2 is used to fix the film material group 1 in the backlight source. The setting of the diffusion layer 3 on the light-emitting surface of the fixed structure 2 can make the backlight light emitted from the light-emitting surface of the fixed structure 2 ...

Embodiment 2

[0042] This embodiment provides a backlight source. The difference from Embodiment 1 is that Figure 7 As shown, the diffusion layer 3 is made of quantum dot material. Quantum dots have a particle size in the range of 1-10 nm.

[0043] Quantum dots within this particle size range can be excited by the blue part of the white light emitted by the backlight. On the one hand, this can increase the brightness of the light emitted from the light-emitting surface of the fixed structure 2 after passing through the diffusion layer 3. On the other hand, the white light After the quantum dot material is excited by the blue part in the figure, since the quantum dot material is nanoscale, it will diffract the light passing through the diffusion layer 3, so that the irradiation direction of the light passing through the diffusion layer 3 is randomly distributed, thereby improving the fixed structure The brightness difference between the edge of the visible area corresponding to 2 and other...

Embodiment 3

[0046] This embodiment provides a display panel, including the backlight source in any one of Embodiments 1-2.

[0047] By adopting the backlight source in any one of the embodiments 1-2, the shadow appearing on the edge of the visible area of the corresponding fixed structure of the display panel is eliminated, thereby improving the display effect of the display panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com