Ventilation system for lng receiving terminal

A technology of ventilation system and receiving terminal, applied in the field of ventilation system, can solve the problems of aggravating the adverse effects of surrounding concrete structures, affecting the normal operation of concrete structures, and difficult to exchange, and achieving the effects of simple construction, flexible layout and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

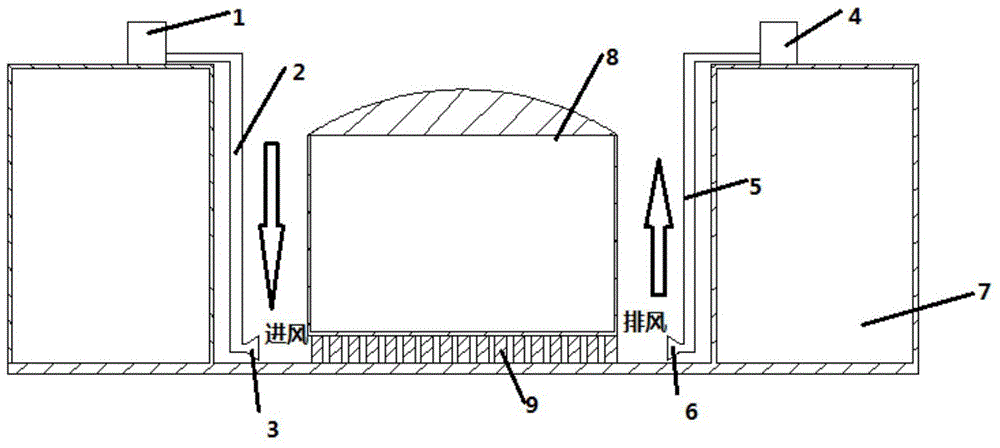

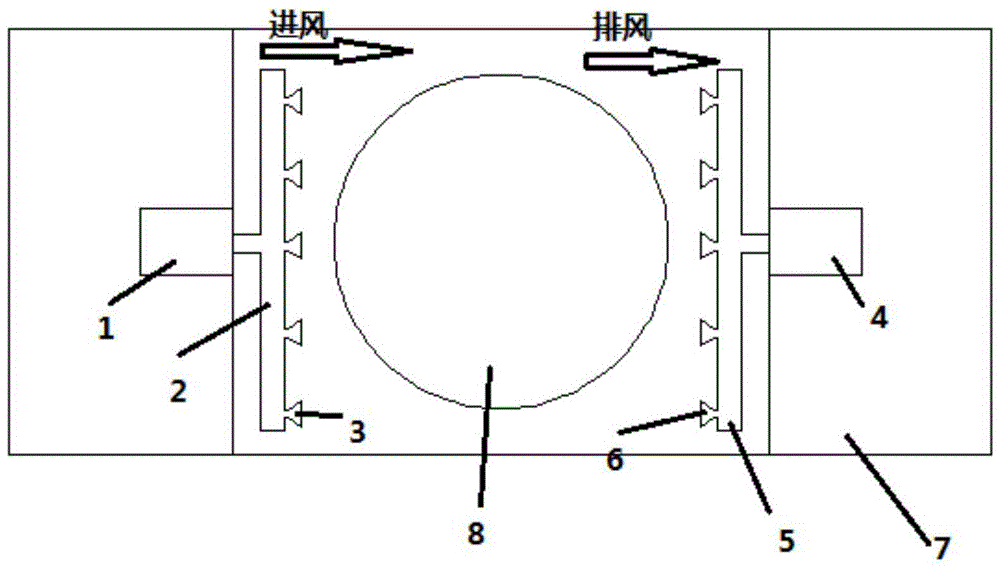

[0027] like figure 1 and figure 2 Shown is the ventilation system for the LNG receiving terminal of the present invention, which includes a blower fan 1 , an exhaust fan 4 and LNG storage tank supporting short column groups 9 . In the present invention, the support column group 9 of the LNG storage tank includes a plurality of concrete support columns with a height of 0.5m-1.5m for supporting the LNG storage tank 8 and ensuring ventilation at the bottom of the LNG storage tank 8 . The air supply fan 1 and the exhaust fan 4 are all arranged on the top of the LNG receiving terminal 7, and the air supply fan 1 is connected with the air supply ventilation pipe 2, and the air supply ventilation pipe 2 and the exhaust air ventilation pipe 5 are all extended to the LNG receiving terminal. The bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com