Rolling mill vibration mark identification method based on kurtosis time-varying signal

A technology of time-varying signals and identification methods, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., and can solve problems such as low identification accuracy and complex vibration sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

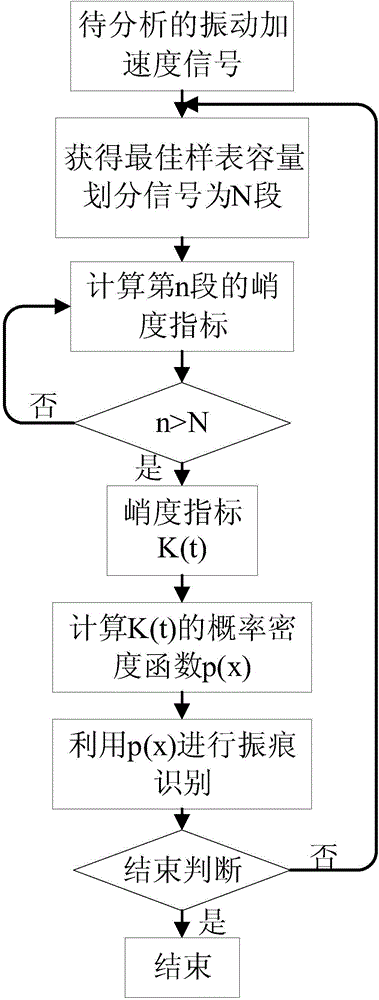

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

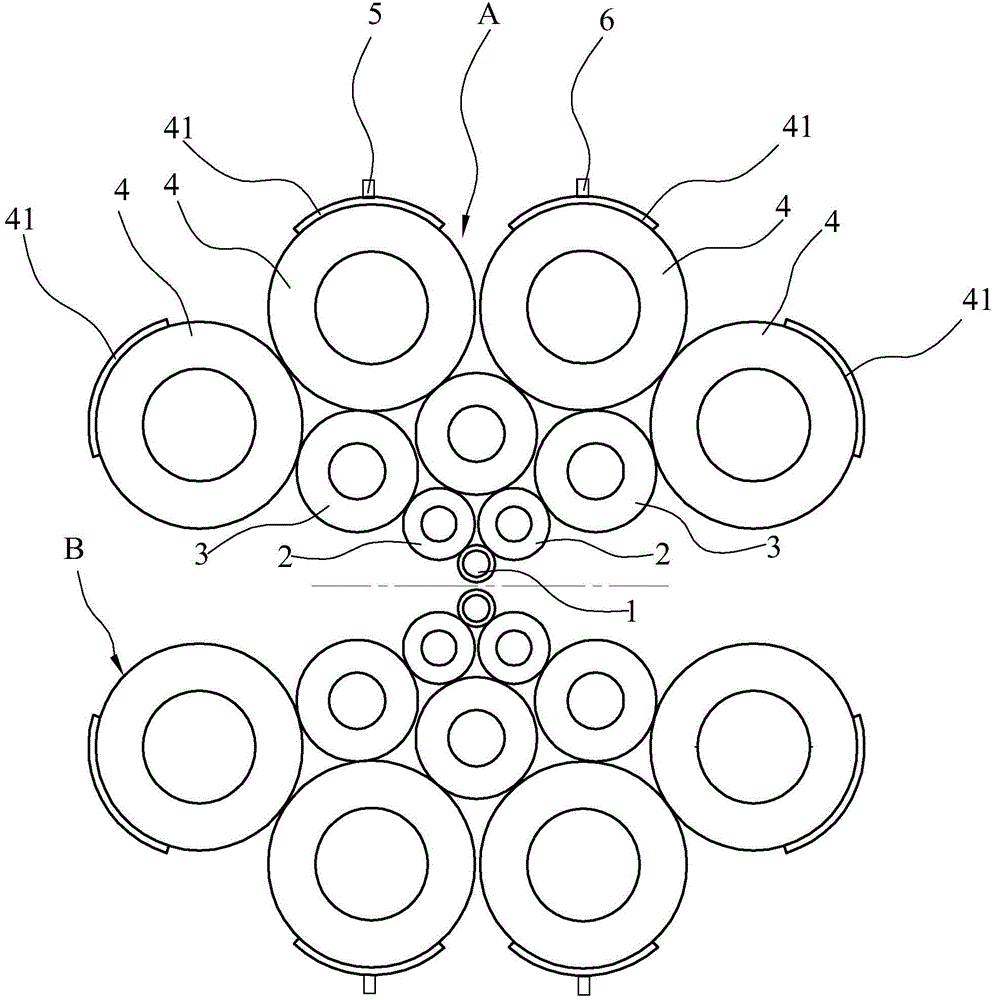

[0018] Such as figure 1 Shown is a 20-high rolling mill equipped with a vibration acceleration sensor, which includes an upper part A and a lower part B arranged symmetrically on the upper and lower sides, wherein the upper part A includes work rolls 1 arranged in sequence from the inside to the outside, the middle Roll 2, drive roll 3 and support roll 4, of which 1 is work roll 1, and 2 are intermediate roll 2, which are symmetrically arranged above work roll 1 with work roll 1 as a symmetrical axis, and 3 drive rolls 3 are supported. There are four rollers 4, which are arranged outward in sequence in the same way as the intermediate rollers 2. The vibration acceleration sensor is used to collect the acceleration signal of the vibrating twenty-high rolling mill, including the first vibration acceleration sensor 5 and the second vibration acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com