Concrete slump tester

A concrete and slump technology, applied in the direction of material inspection products, etc., can solve the problems of difficult to control the degree of concrete filling slump, uneven ground, and irregular distance measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

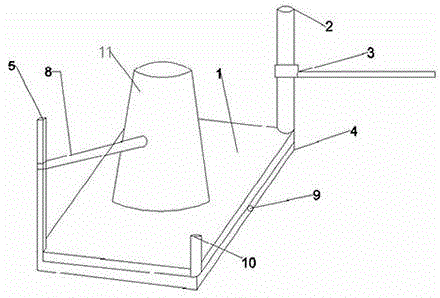

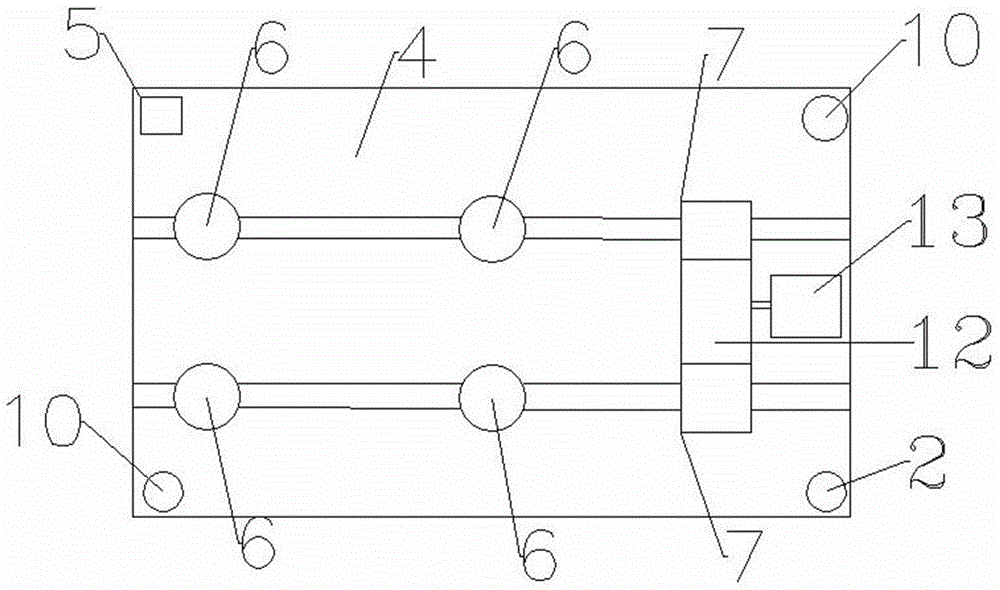

[0010] In Fig. 1, the four corners of the base 4 are respectively connected with a square rod 5, two round rods 10 and a scale 2.

[0011] In Fig. 2, two rotating shafts 6 with hemispheres are installed inside the base, and a gear 7 is installed on the rotating shaft, and the gear and the gear transmission 12 are connected to the motor 13. The motor is controlled via switch 9.

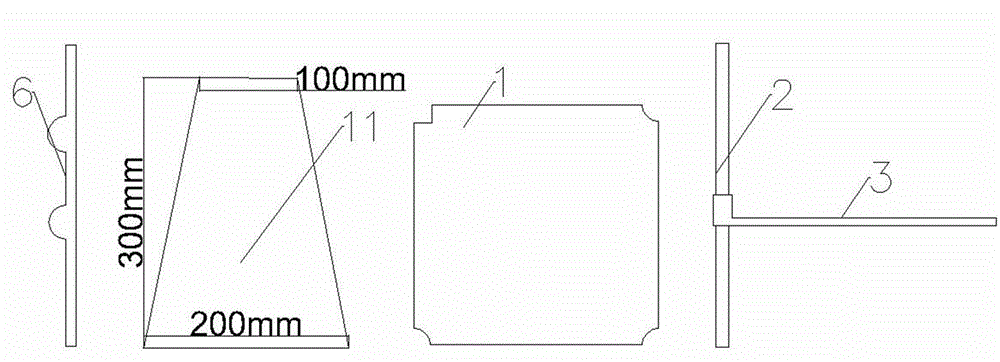

[0012] In Fig. 3, the size of the slump cylinder 11 is that the upper and lower diameters are 100mm and 200mm, and the height is 300mm. The slump cylinder 11 is welded to the slump cylinder connecting rod 8 . The circular scale 2 takes the 0 scale at the height of 300mm, and marks the millimeter scale downwards successively. The measuring rod 3 is sleeved on the scale through a circular tube. The notches at the four corners of the test platform 1 are in the same position and size as the square rod 5, the round rod 10, and the scale 2 in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com