Axis-shift optical anti-shake lens drive device

A lens drive device and anti-shake technology, which is applied in optics, projection devices, optical components, etc., can solve the problems of equipment battery life impact and power consumption increase, so as to facilitate battery life, meet miniaturization, and low power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

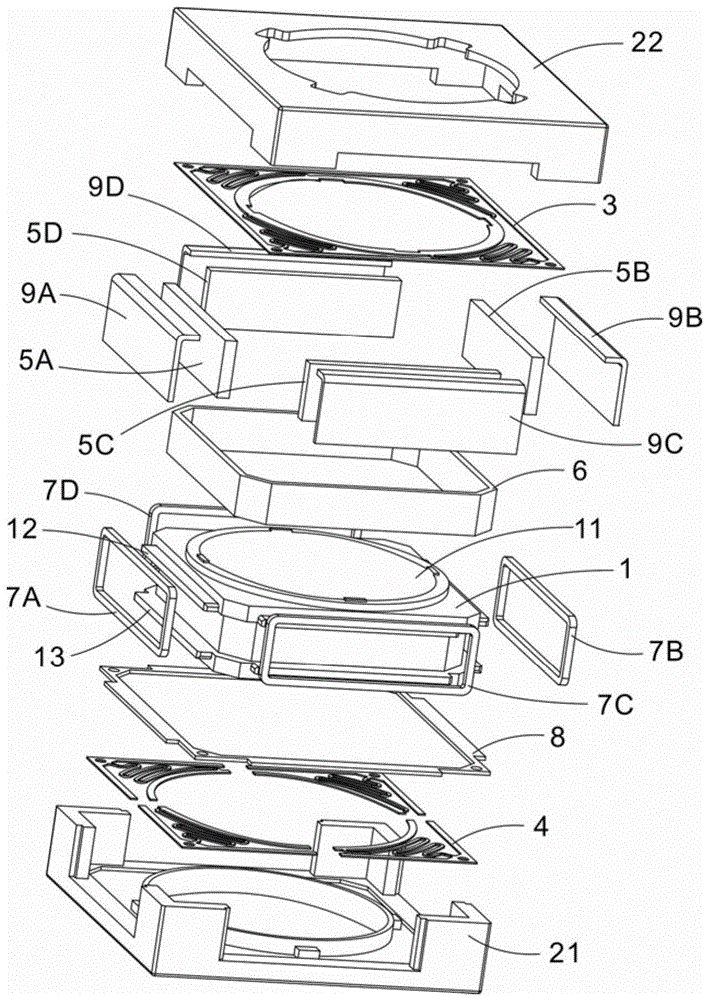

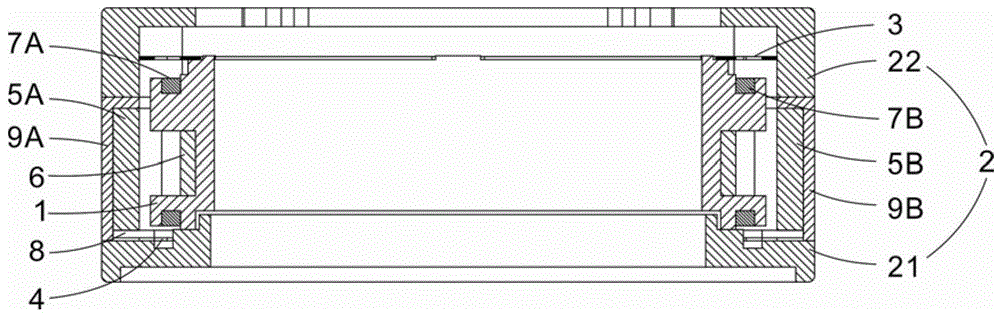

[0048] like figure 1 and figure 2 As shown, it is an embodiment of the present invention, and the axis-shifting optical anti-shake lens driving device in this embodiment includes:

[0049] The carrier 1 has a hollow inner cylinder 11 for combining the lens unit;

[0050] The housing 2 includes a base 21 and an upper cover 22 for accommodating the carrier 1;

[0051] The upper reed 3 is used to elastically connect the upper part of the carrier 1 to the housing 2;

[0052] The lower spring 4 is used to elastically connect the lower part of the carrier 1 to the housing 2;

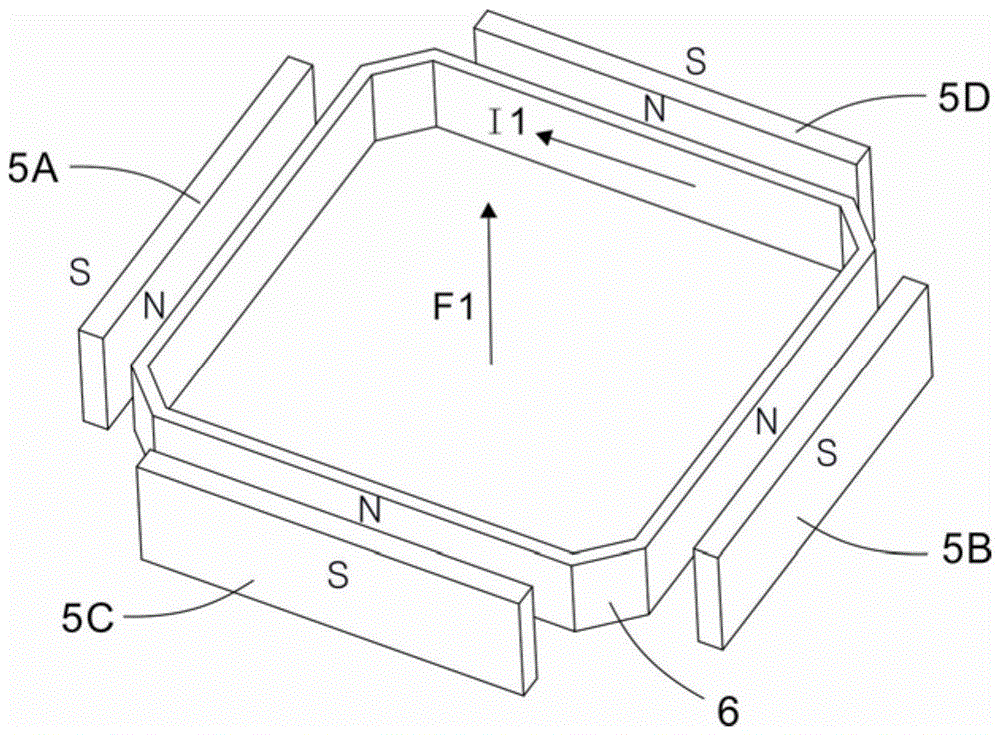

[0053] The permanent magnets 5A, 5B, 5C, and 5D are fixed in the housing 2, and the permanent magnets are equidistantly distributed around the axis of the inner cylinder 11 and their homopolar faces face the carrier 1;

[0054] The focusing excitation coil 6 is wound on the outer edge of the carrier 1 and its coil plane is perpendicular to the axis of the inner cylinder 11. After it is energized, it coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com