Internet of Things system for supply chain management

An Internet of Things system and supply chain management technology, applied in logistics, data processing applications, instruments, etc., can solve problems such as poor accuracy and low entry efficiency, and achieve poor accuracy, solve low entry efficiency, and improve accuracy and entry. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the technical solution provided by the embodiment of this application, the electronic equipment scans the electronic label to obtain and review the goods information, avoiding manual entry and review of incoming and outgoing goods, so as to solve the problem of receiving and shipping information caused by manual entry of information in the prior art The technical problems of poor accuracy and low input efficiency improve the accuracy and input efficiency of inbound and outbound cargo information.

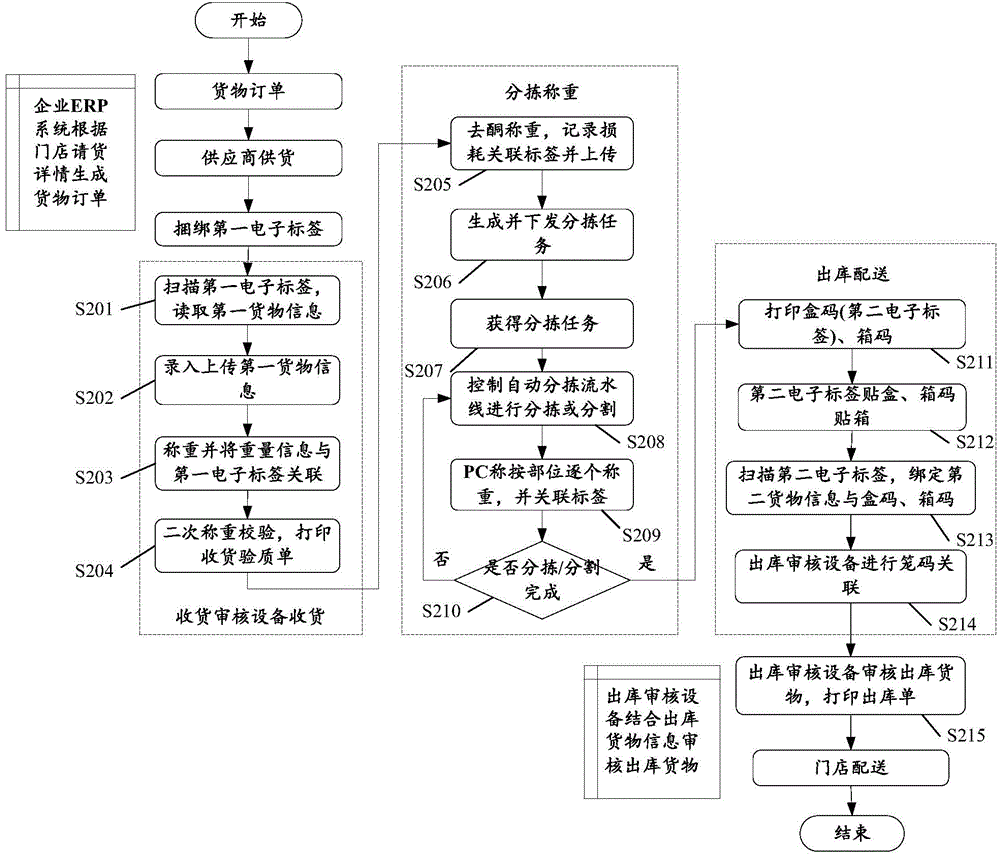

[0025] The main realization principles, specific implementation methods and corresponding beneficial effects that can be achieved of the technical solutions of the embodiments of the present application will be described in detail below in conjunction with the accompanying drawings.

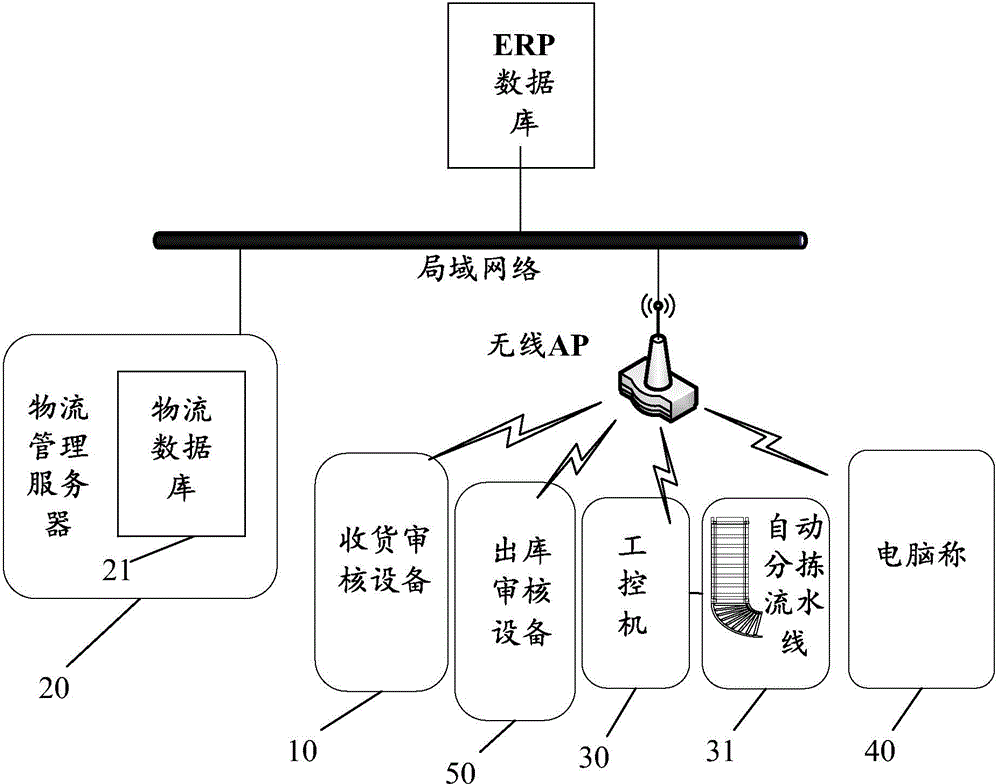

[0026] Please refer to figure 1 , the embodiment of the present application provides an IoT system for supply chain management, the system includes:

[0027] The goods receipt review device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com