Cooling device for vertical motor of double-layer structure

A cooling device, vertical motor technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of low cooling efficiency, failure to meet the use requirements, and inability to effectively enter the cooling device of the outer plate, etc., to achieve protection performance Good effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

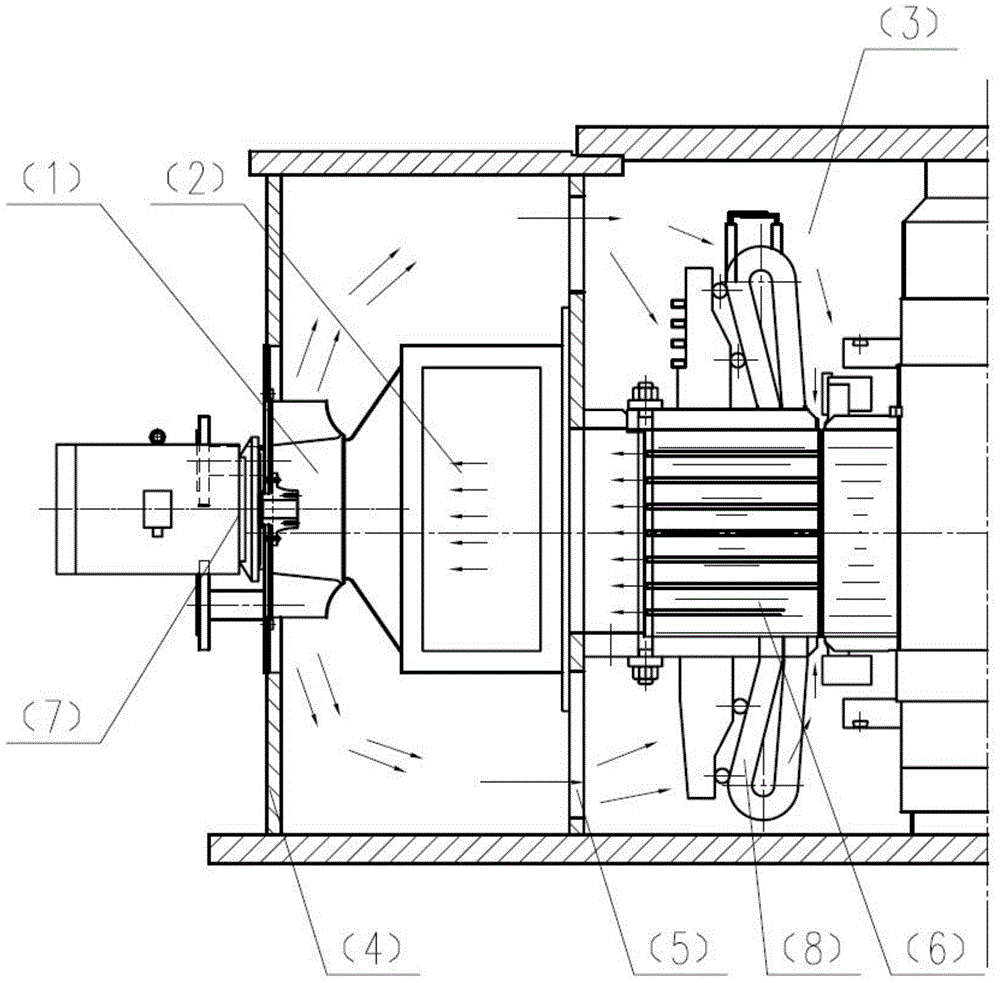

[0009] like figure 1 As shown, a double-layer structure vertical motor cooling device, the cooling device 7 is an integral structure, composed of a fan 1 and an air-water cooler 2, the fan 1 and the air-water cooler 2 are located on the inner panel of the double-layer structure vertical motor 5 and the outer plate 4, the fan 1 and the stator core 6 are in the same horizontal plane, the outer plate 4 is in contact with the stator core 6, the air-water cooler 2 is fixed on the outer side of the outer plate 4 by bolts, and the fan 1 passes through the inner plate and passes through the bolts Fixed on the outside of the air-water cooler 2.

[0010] The cooling device 7 is composed of the fan 1 and the air-water cooler 2 connected to each other in the horizontal direction to form an overall structure. The fan 1 has two sets of independent fan blades, and the blowing direction is vertically upward and vertically downward respectively. The air-water cooler 2 There is a separate wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com