High-strength impact-resistant composite shell

A high-strength alloy and high-strength technology, applied in the field of materials, can solve the problems of high cost of use, and achieve the effects of low maintenance cost, good protection performance, and good repair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

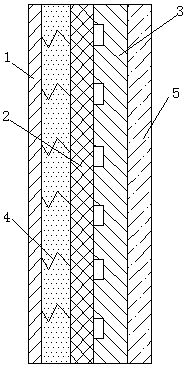

[0012] A high-strength, impact-resistant composite shell, comprising a memory high-strength alloy 1 with a surface layer, an elastic layer 2 arranged inside the memory high-strength alloy 1, and an elastic layer 2 arranged inside the elastic layer 2 for supporting the elastic layer 2 The high-strength support layer 3;

[0013] A cavity is formed between the memory high-strength alloy 1 and the elastic layer 2, and a cooling medium is arranged in the cavity.

[0014] The cavity formed between the elastic layer 2 and the memory high-strength alloy 1 is provided with a strong spring 4, one end of the strong spring 4 is supported on the elastic layer 2, and the other end of the strong spring 4 is supported on the memory height Strength alloy 1 on.

[0015] The inner surface of the high-strength support layer 3 is provided with a buffer layer 5, the buffer layer 5 is a sponge layer with a certain thickness, and the sponge layer is wrapped with cloth.

[0016] The elastic layer 2 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com