Method of producing a syringe barrel for medical purposes and device for carrying out said method

A technology for a syringe barrel and a delivery device, which is applied in the directions of syringes, hypodermic injection devices, and other medical devices, can solve problems such as expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

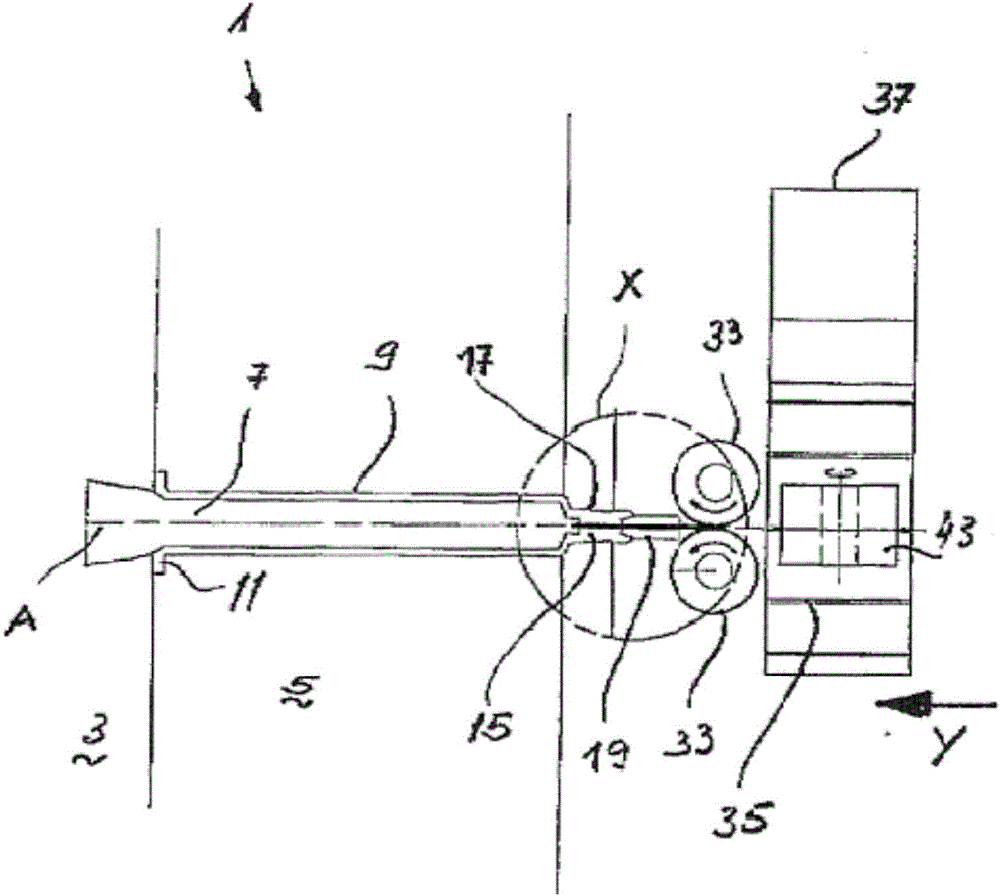

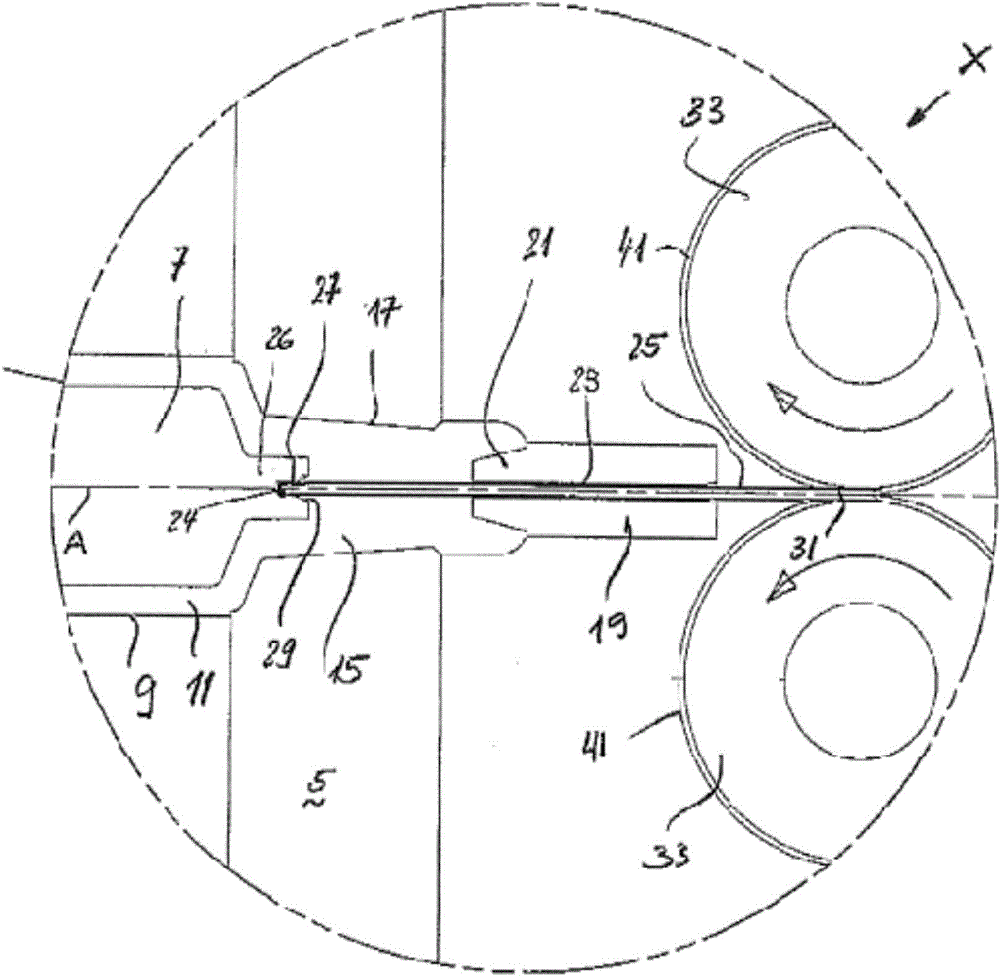

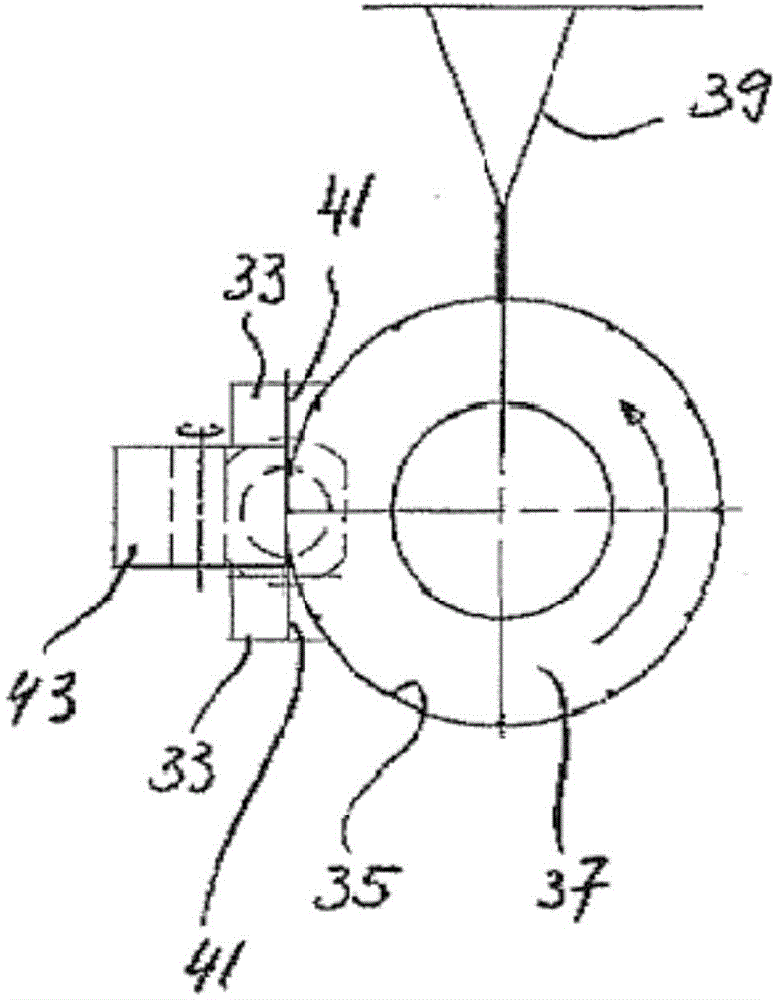

[0012] Reference number 3 shows the movable parts of the injection mold 1 in a schematic diagram, and reference number 5 shows the fixed parts of the injection mold 1 . On the movable part 3 of the injection mold 1 a core 7 is fixed, while the core 7 is inserted into the cavity 9 of the syringe barrel 11 in the fixed mold part 5 . Next, it can be seen in the figure on the right, for example, that next to the cylindrical cavity 9 there is a conical cavity portion 17 formed by the collection needle 15 . Extending in the needle guide tube 19 at the end of the hollow portion 17 is a conical blunt end 21 . An axial bore 23 in the guide tube 19 exhibits a diameter into which the rear end tail 24 of the needle 25 can be inserted substantially without play and sealingly when spraying.

[0013] The free end 26 of the core 7 forms a blind bore 27 which essentially comprises a conical inlet region 29 at the input.

[0014] The needle 25 with the tip fitted at the front end 31 is held b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap