Hexagonal tip grinding method

A hexagonal tip and grinding technology, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding machines, etc., can solve problems such as uneven distribution, differences in inclination angles, and inability to achieve machining accuracy, so as to overcome defects and implement simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

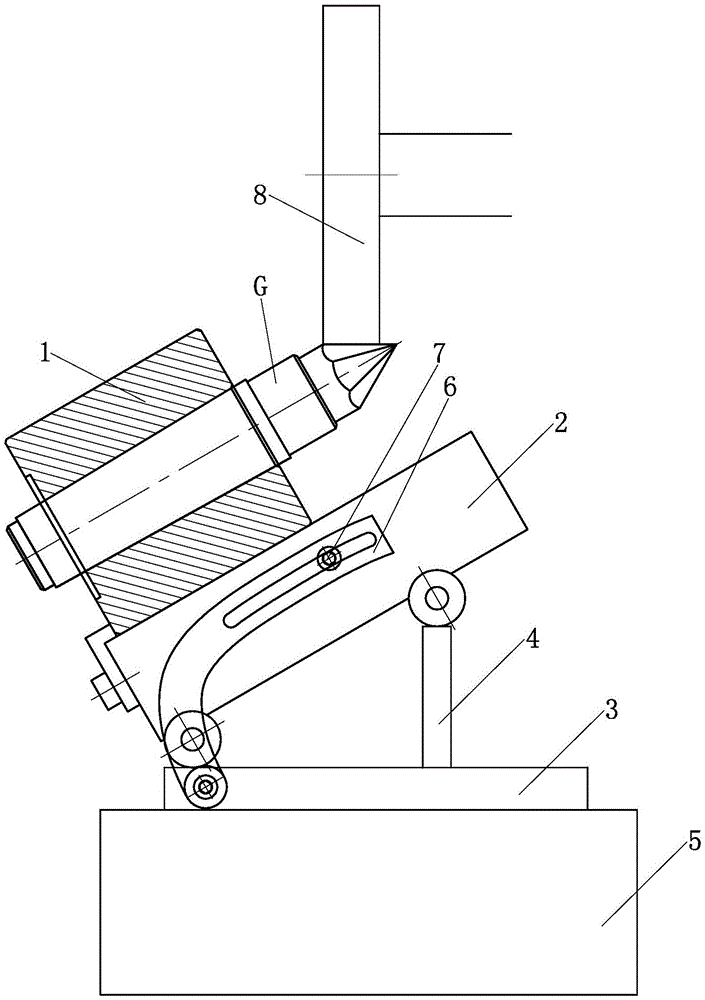

[0016] Such as figure 1 , 2 , Shown in 3, a kind of hexagonal tip grinding method is characterized in that comprising the steps:

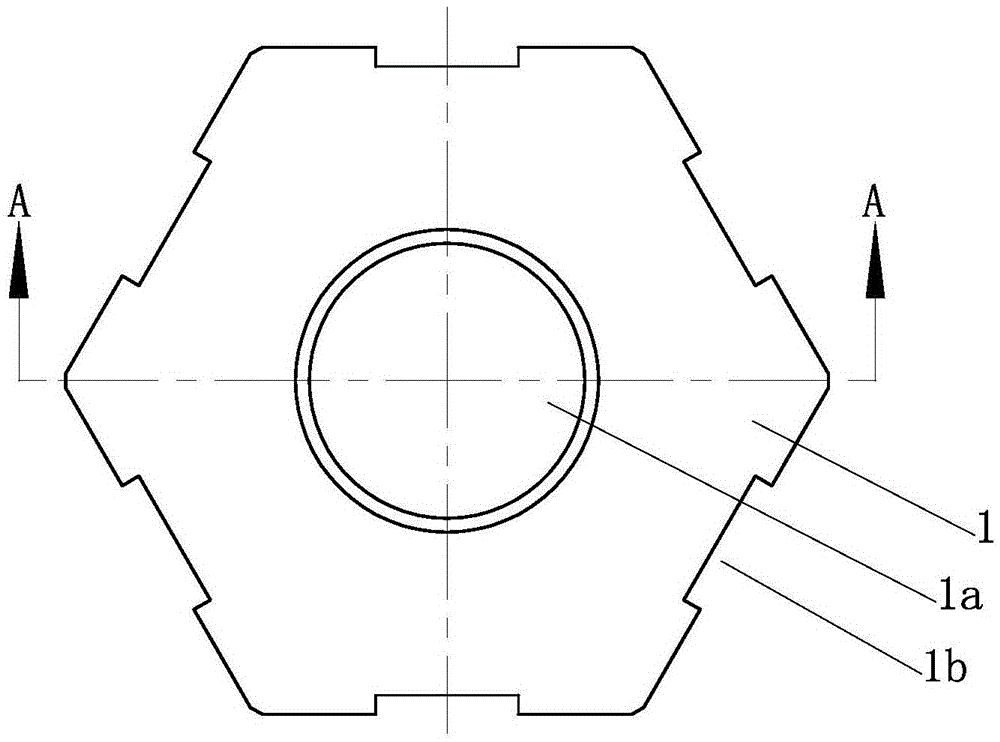

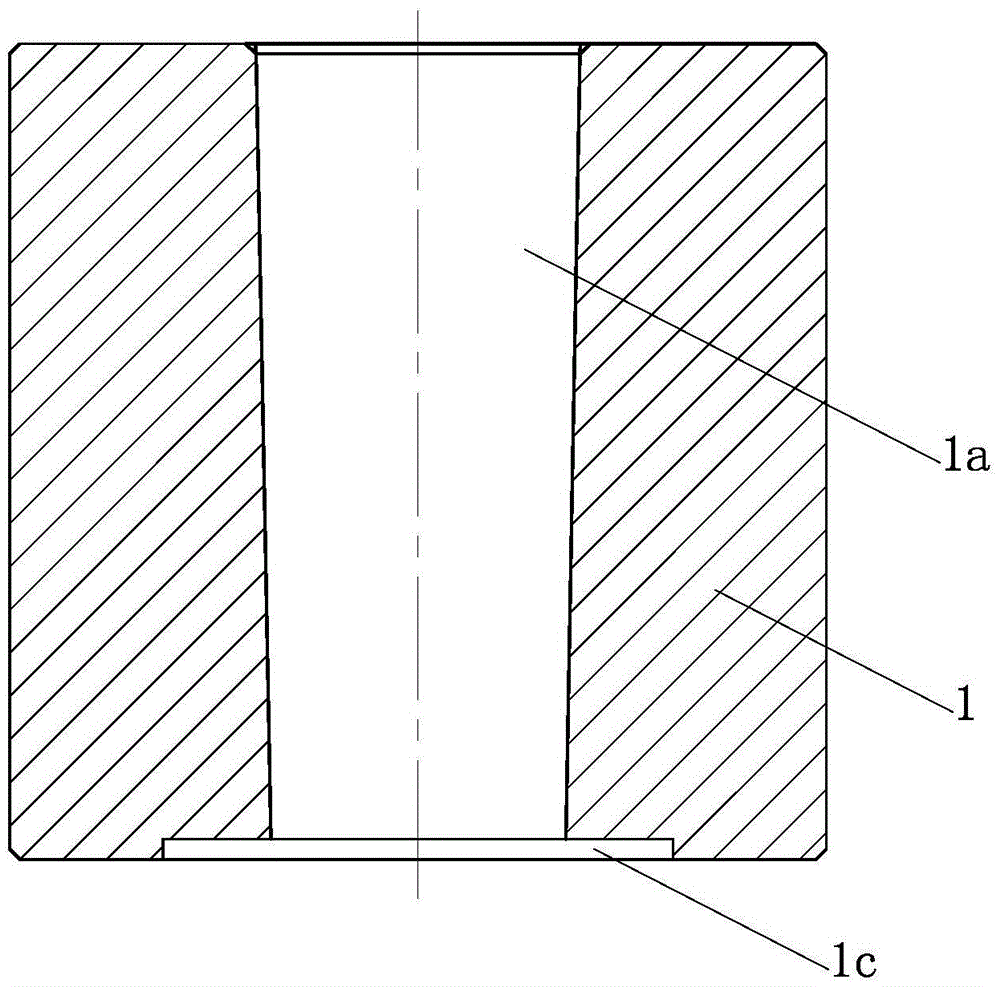

[0017] Step a: Select an auxiliary device 1 of a corresponding size according to the outer diameter of the hexagonal center G. The auxiliary device is a regular hexagonal prism structure, and its manufacturing material is high carbon steel or iron, and the six surfaces of the auxiliary device 1 are working surfaces, and The central hole 1a of the auxiliary device 1 is a Mo's taper hole matched with the top; in addition, the six planes of the auxiliary device 1 are provided with a through groove 1b, which runs through both ends of the auxiliary device 1; There is a groove 1c in the center of the end surface of tool 1, which communicates with the small end of the central hole 1a, and the diameter of the groove 1c is larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com