Special clamp for drilling cambered surface of shaft part and use method

A technology of shaft parts and special fixtures, which is applied in the direction of drilling molds for workpieces, etc., can solve the problems of increased labor intensity of operators, difficulty in positioning and fixing workpieces, and low work efficiency, so as to reduce instability and simple structure , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In conjunction with the summary of the invention and the accompanying drawings, describe in detail the specific implementation of the invention

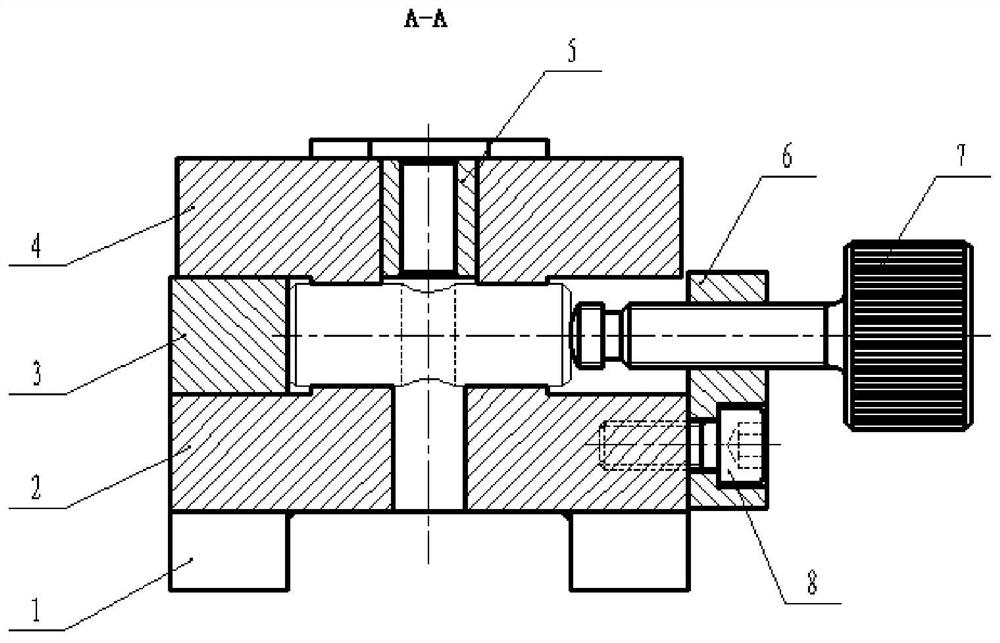

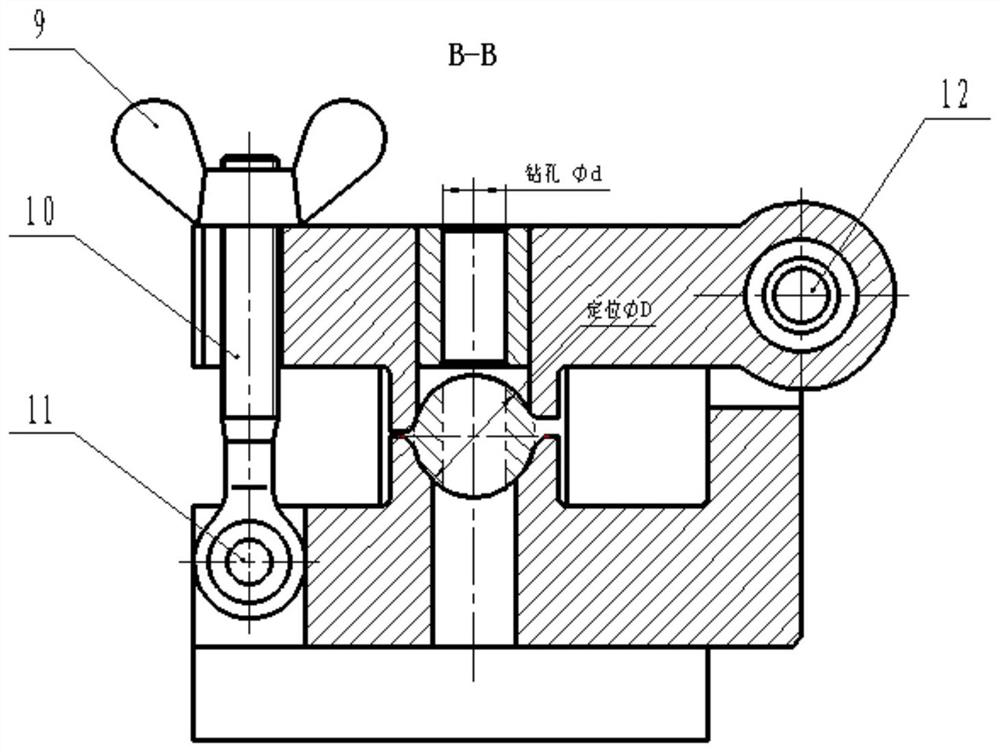

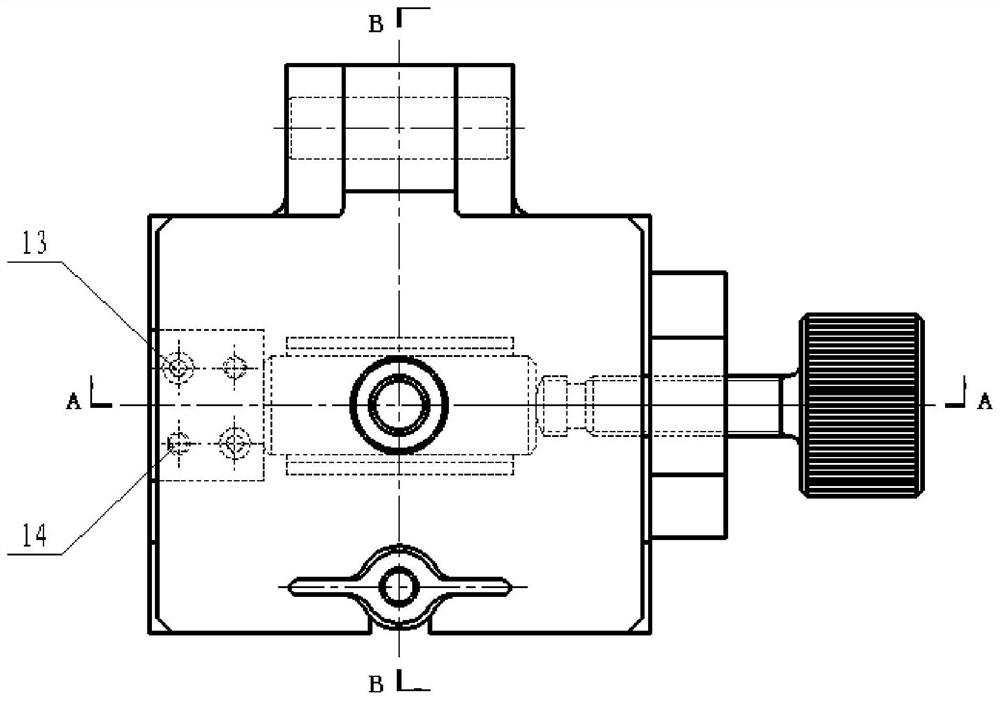

[0023] The special fixture for drilling arc surface of shaft parts such as figure 1 As shown, it includes a base 2 and a drilling template 4; the base 2 is sequentially provided with a semi-cylindrical baffle plate 3, a positioning block A, and a support plate 6; the baffle plate 3, the positioning block A, and a support plate 6. The center remains on the same plane; the drilling template 4 is provided with a positioning block B with a semi-cylindrical cavity, and the positioning block B and the positioning block A are closed to ensure concentricity; the drilling template 4 is connected to the base through a cylindrical pin 12 2 are connected to form a hinged mechanism to achieve the purpose of simple and fast loading and unloading of parts; the edge forming the opening end of the hinged mechanism is provided with a swing bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com