Device and method for measuring shearing property of transverse isotropic material

A technology with transverse isotropy and performance, applied in the direction of applying stable shear force to test the strength of materials, etc., can solve the problems of difficult realization of loading device and few measurement methods, and achieve the effect of accurate test data and intuitive and convenient parameter measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

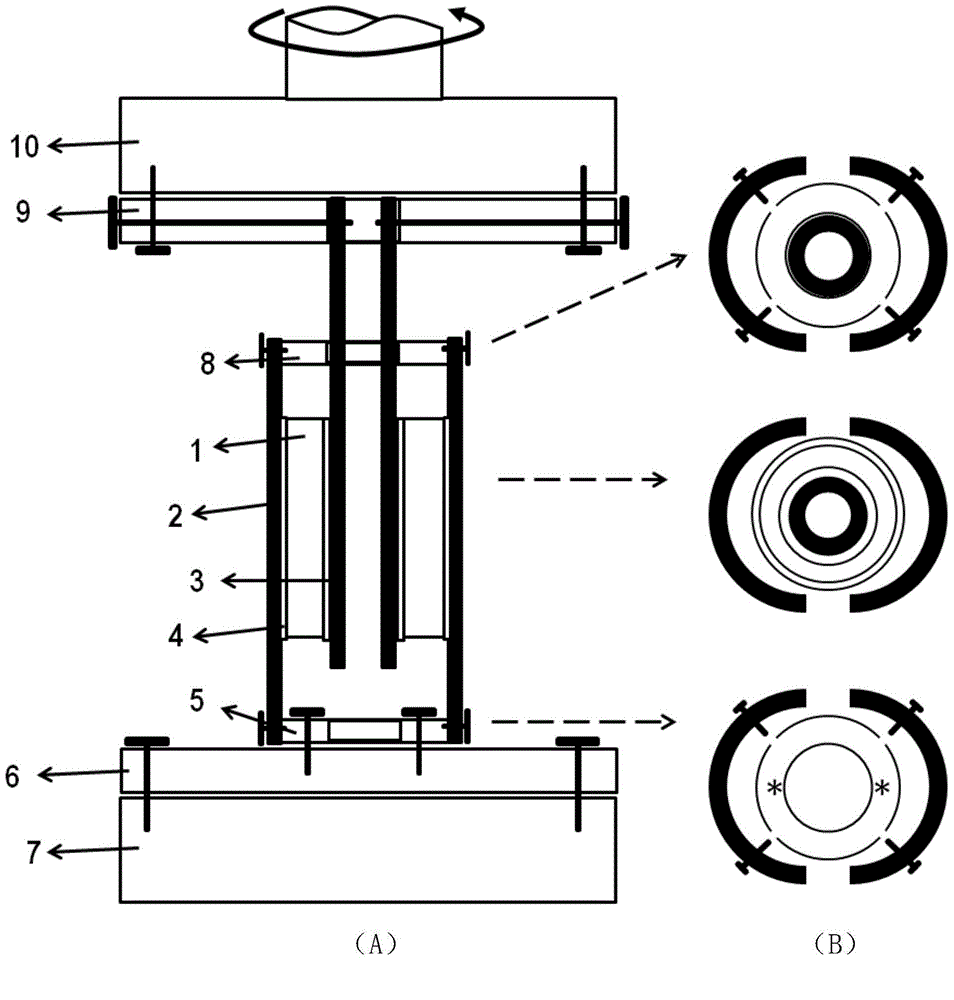

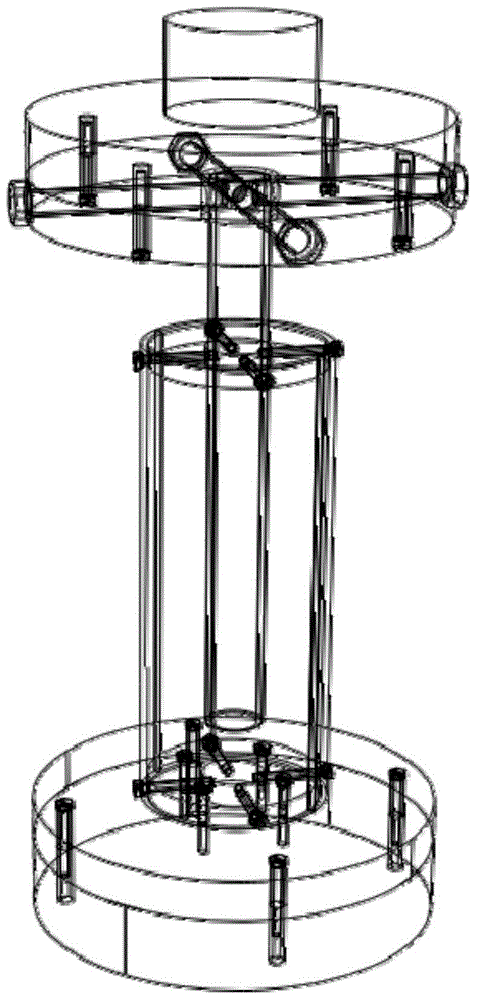

[0024] Such as Figure 1~2 As shown, the device for measuring the shear performance of transversely isotropic materials of the present invention includes a thin-walled tubular test piece 1, a fixed outer tube 2, a rotating inner tube 3, structural glue 4, a lower positioning ring 5, a lower connecting plate 6, Torque sensor 7, upper positioning ring 8, upper connection plate 9, flange plate 10.

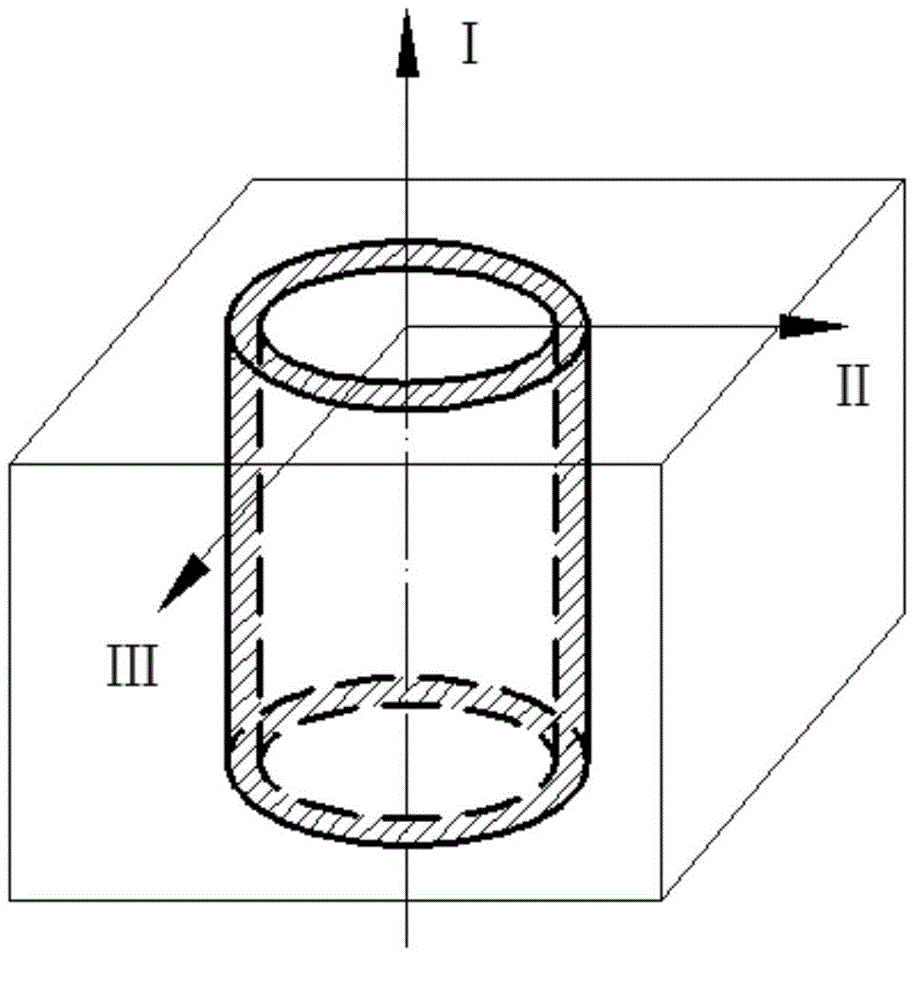

[0025] refer to image 3 , the transversely isotropic material is processed into a thin-walled tubular specimen, where the axial direction is direction I, and the cross-section is perpendicular to each other (transverse direction) II, III. Specifically: first drill holes along the material direction I and remove the hole core to obtain the cylindrical inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com