A method for predicting the height of water-conducting fault zones in filling mining

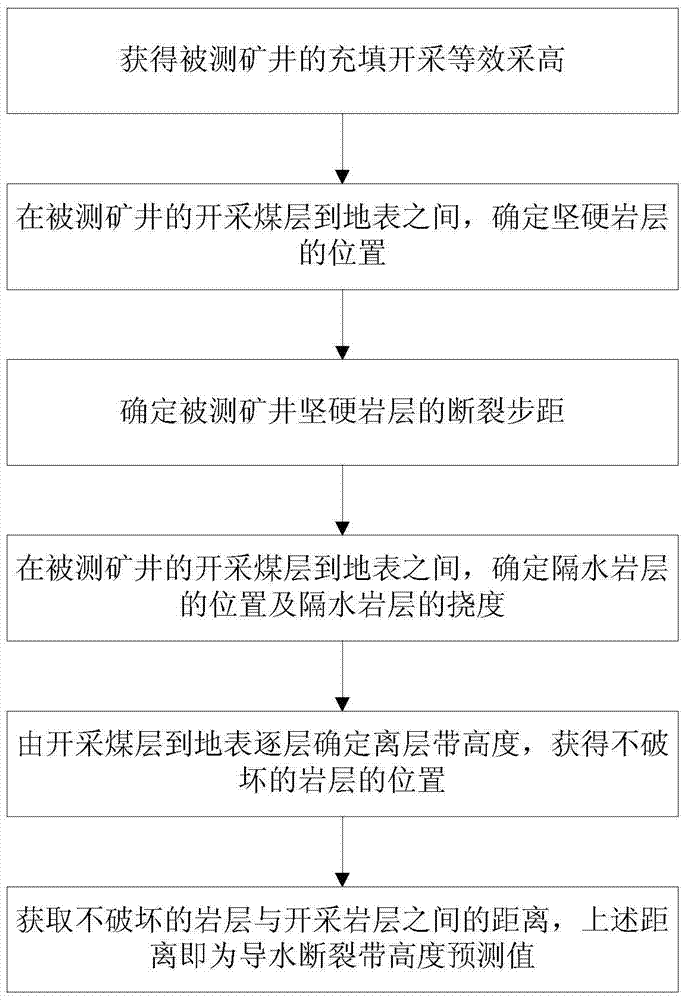

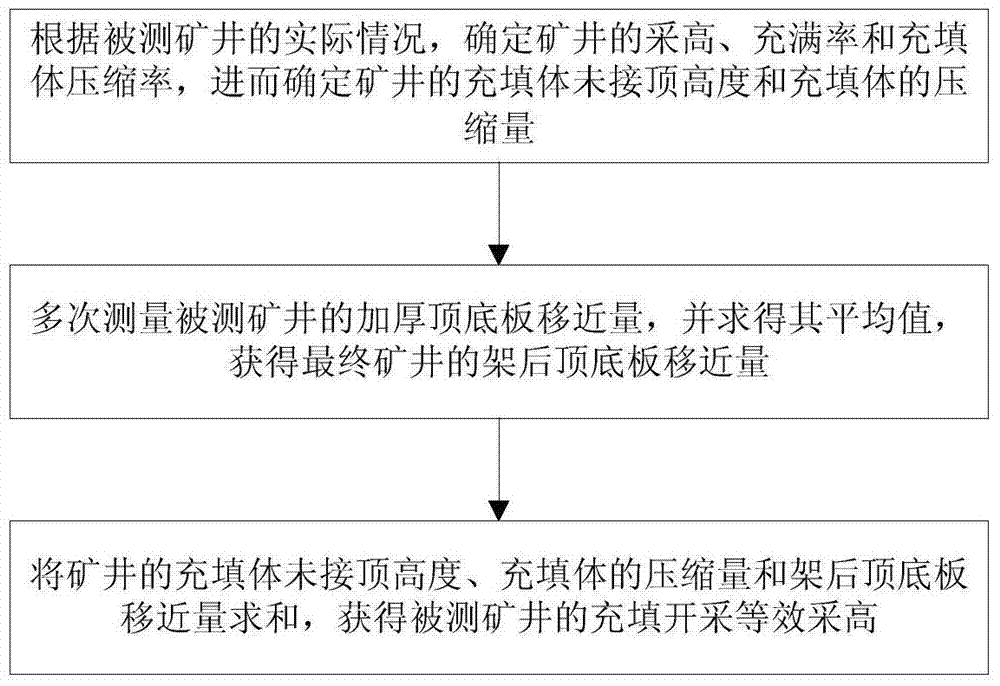

A prediction method and fault zone technology, applied in the field of mine production safety, can solve the problems of poor accuracy of water-conducting fault zones, insufficient consideration of roof lithology and horizon distribution, etc., and achieve accurate and specific results in the calculation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

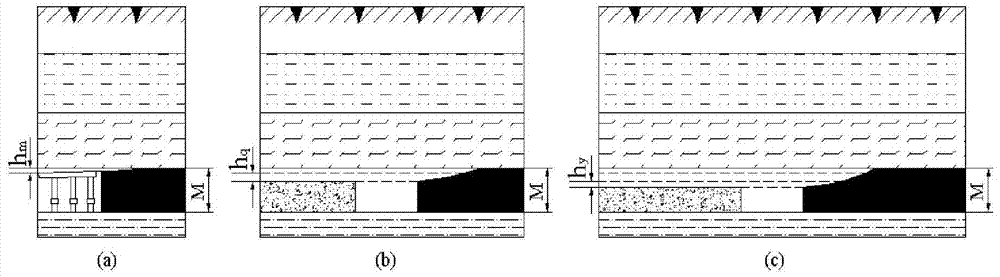

[0048] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0049] In the embodiment of the present invention, the Xima Coal Mine is taken as an example for illustration. No. 13 coal of the Xima Coal Mine is the main mining coal seam, and the coal seam is stable in occurrence and excellent in coal quality. Taking the 1327 work as an example for research and analysis, the roof management method of the working face is paste-like filling, the filling method is gravity filling, and the filling aggregate is mainly crushed coal gangue; fly ash and composite water reducer are added to the filling. Ordinary Portland cement marked No. 325 was added as a gelling agent, and the maximum compression ratio measured by the filling body laboratory was 3.65%. The mining method was inclined longwall retreating upward mining, the average inclination angle of the working face was 9°, and the inclination length was 501.9 m, the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com