Electromagnet with buffer structure

A buffer structure and electromagnet technology, applied in the field of electromagnets, can solve the problems of large electromagnet volume, large current, and unfavorable product miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

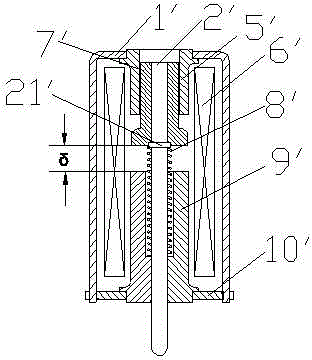

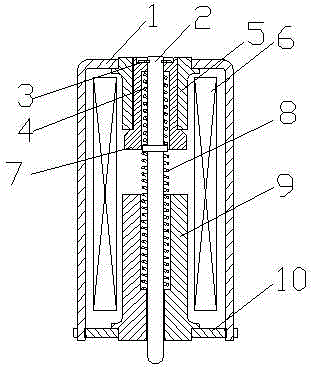

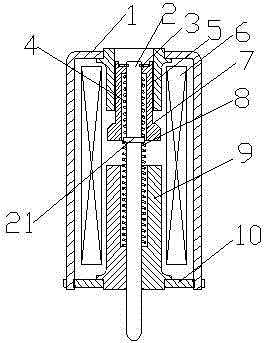

[0017] Example: see Figure 2-5 Shown:

[0018] An electromagnet with a buffer structure, including a yoke, a push rod 2, a coil 6, a moving end magnetic pole 7, a return spring 8, and a static end magnetic pole 9;

[0019] The yoke includes an intermediate yoke 1 , a moving yoke 5 and a stationary yoke 10 . The magnetic yoke forms a hollow cavity with openings on both sides. A pair of moving end yokes 5 are symmetrically fixed on the left and right sides of the opening of the upper end of the cavity formed by the middle yoke 1, and the static end magnetic poles 9 and a pair of static end yokes 10 are fixed and symmetrically located in the middle magnetic yoke. On the left and right sides of the lower part of the cavity of the yoke 1 , the coil 6 is arranged in the hollow cavity formed by the yoke, and surrounds the static end magnetic pole 9 and the outer side of the moving end yoke 5 . The moving end magnetic pole 7 is arranged in the center hole of the moving end yoke 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com