Multistage gas gun anti-recoil device

An anti-recoil and air cannon technology, applied in the direction of compressed air guns, weapons without explosives, weapon types, etc., can solve the problems of high impact strength of the cannon body, achieve the effect of reducing the bearing strength of the foundation, reducing the rigidity requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

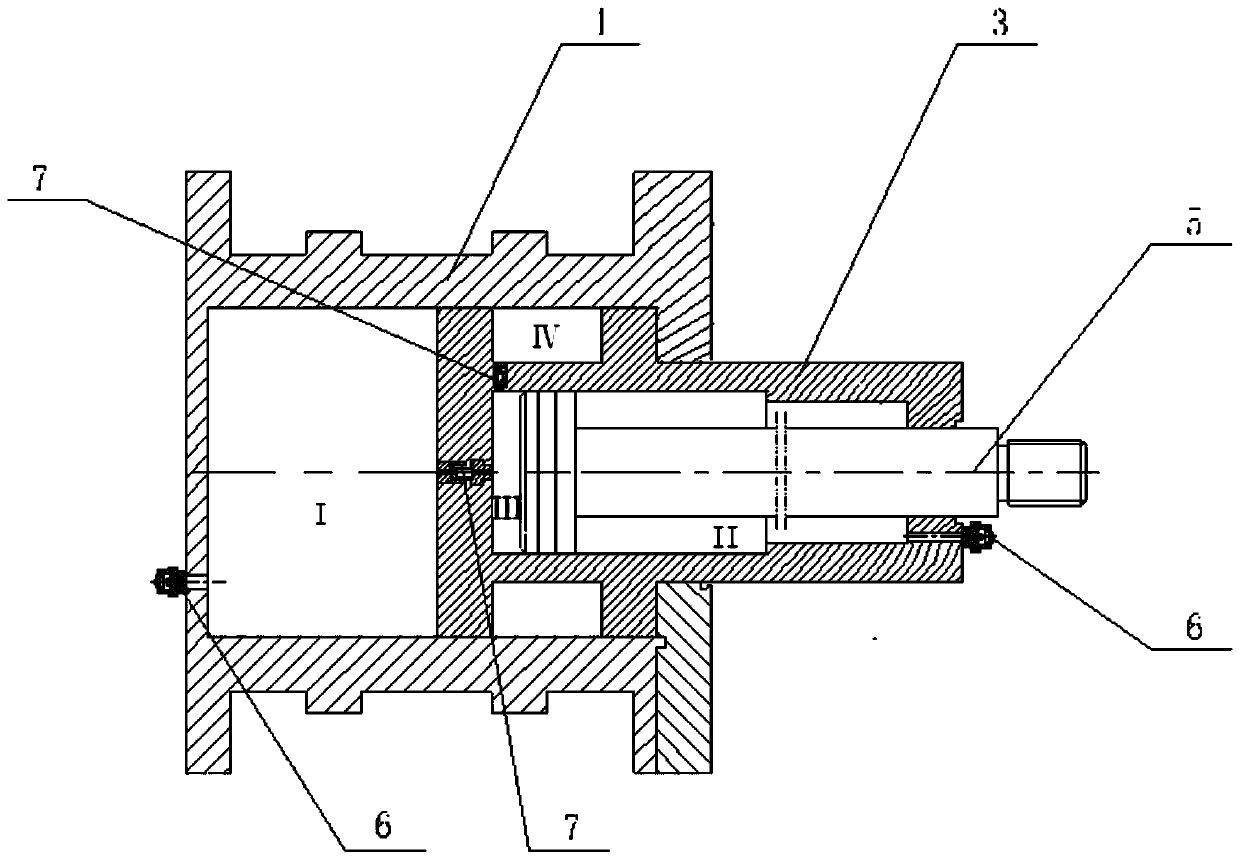

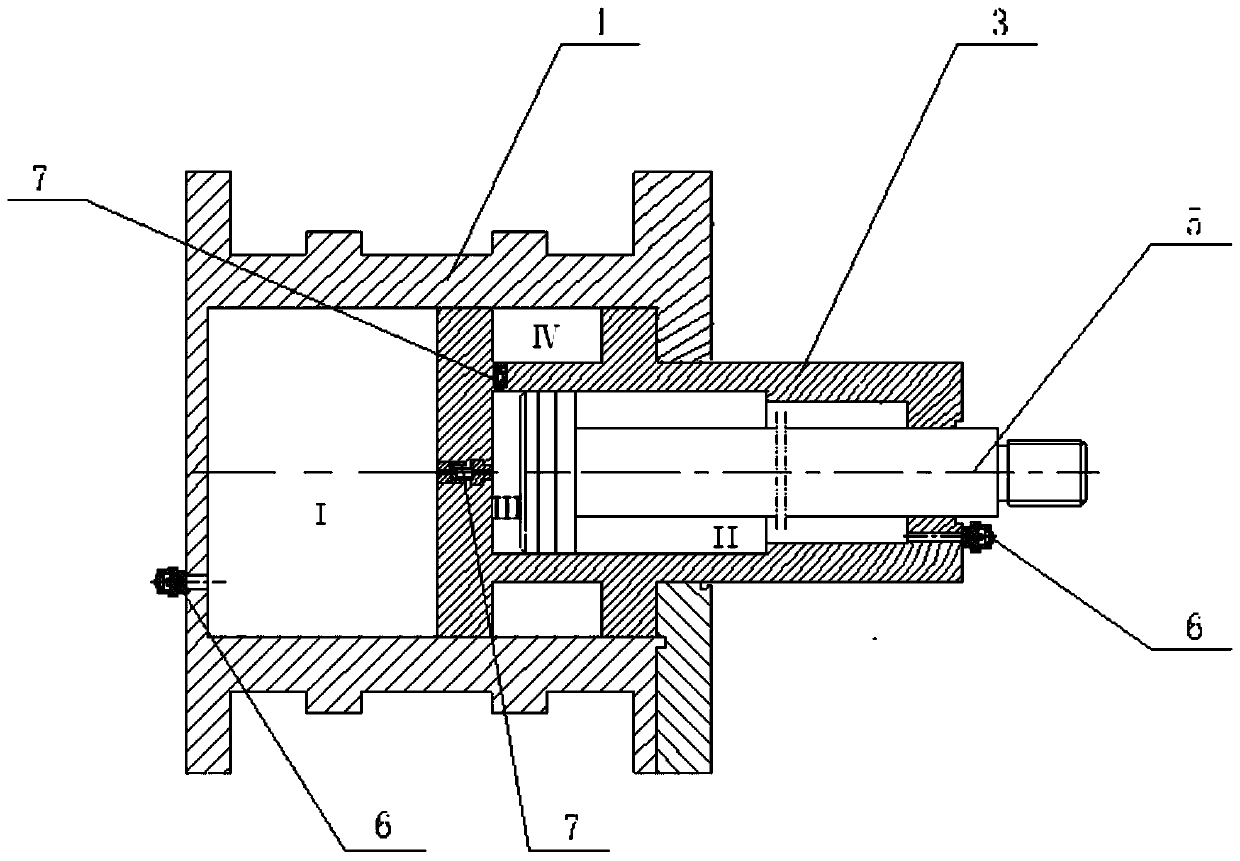

[0014] Such as figure 1 As shown, a multi-stage gas cannon anti-recoil device includes: cylinder body I1, cylinder body II3, buffer rod 5, gas injection valve 6, balance valve 7;

[0015] Cylinder Ⅰ1 is fixedly connected with the gun body, as the retention basis of the whole device, there is no relative movement with the gun body during the firing process of the gas cannon; cylinder Ⅱ3 is fixedly installed on the cylinder Ⅰ1, and the cylinder Ⅰ1 is divided into two airtight chambers One end of the buffer rod 5 is movably connected with the cylinder body II3, and the cylinder body II3 is divided into two airtight chambers; Pressure gas, each chamber is connected through the balance valve, and the pressure of each chamber is adjusted through the balance valve 7 at different stages during the firing process of the gas cannon, so as to realize the buffering of recoil and forward momentum.

Embodiment 2

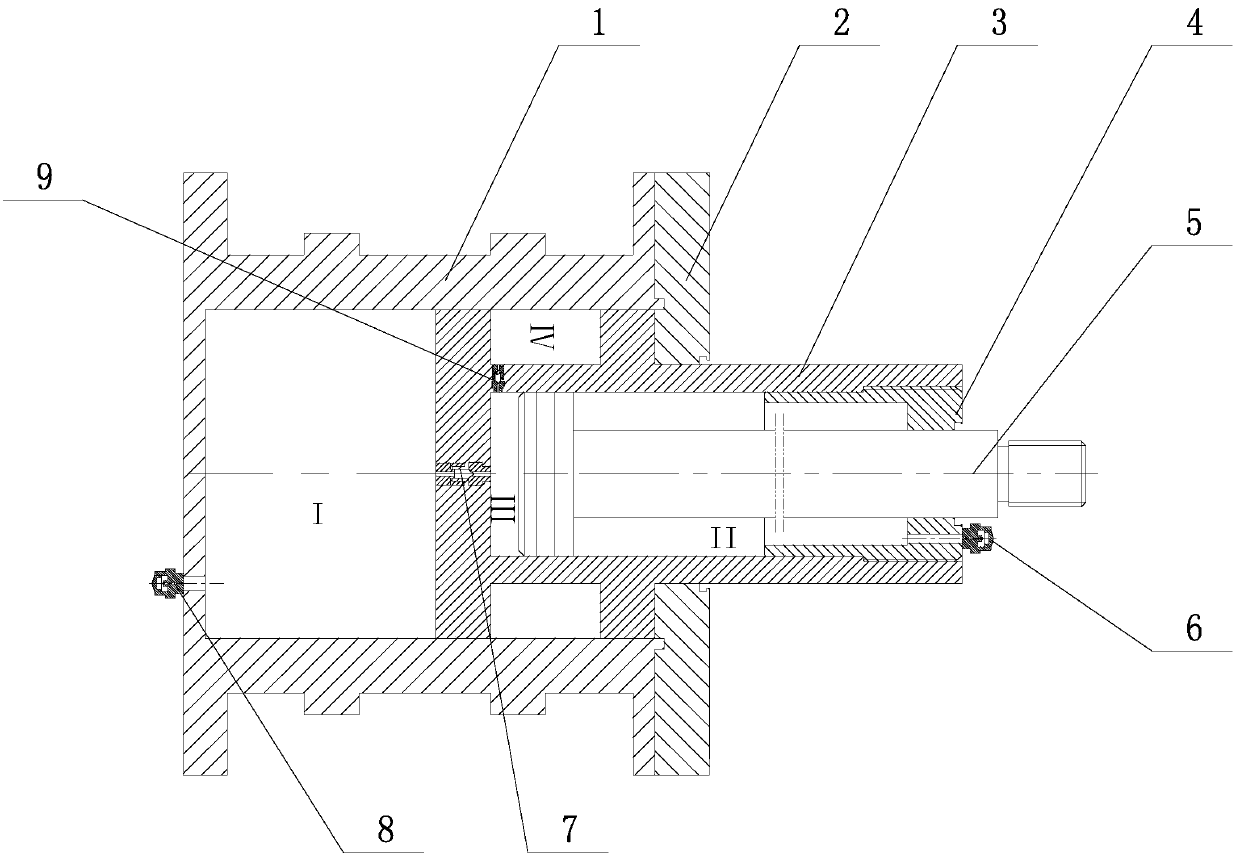

[0017] Such as figure 2 As shown, a multi-stage air cannon anti-recoil device consists of cylinder body I1, cover plate 2, cylinder body II3, fixed seat 4, buffer rod 5, gas injection valve 6, balance valve 7, gas injection valve I8, balance valve Ⅰ9 composition;

[0018] (1) Cylinder block I1 is connected to the gun body (specifically, the barrel of the gas gun), and there is no relative movement with the gun body during the firing of the gas gun;

[0019] (2) The cover plate 2 is used as the connecting cover plate after the assembly of the cylinder body I1 and the cylinder body II3, so that a closed gas chamber is formed between the cylinder body I1 and the cylinder body II3; here, between the cover plate 2 and the cylinder body I1 It can be a separate structure, connected by a sealed connection, or an integrated structure connected by welding, or other structures thought of by those skilled in the art;

[0020] (3) Cylinder body II3, used to connect cylinder body I1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com