Long rubber sleeve and rubber formula thereof

A technology of long rubber tubes and rubber tubes, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., and can solve problems such as difficulty in unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

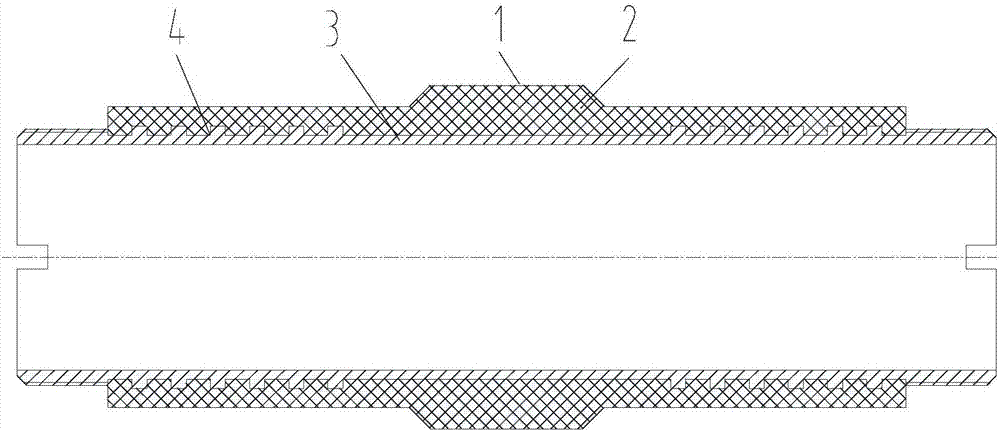

[0014] as attached figure 1 As shown, a long rubber cartridge includes a rubber cartridge main body 1, a liner 3 is installed inside the rubber cartridge main body 1, and the two ends of the liner 3 are vulcanization heads 4, and the vulcanization head 4 and the liner 3 are under pressure as a whole; The outer diameter of the barrel body 1 is 110-114 mm; two layers of pressure-bearing wire mesh 2 are added to the barrel body 1 . The formula of the long rubber cartridge, its components and proportioning are as follows by weight percentage: 92-95% of nitrile rubber and 5-8% of neoprene.

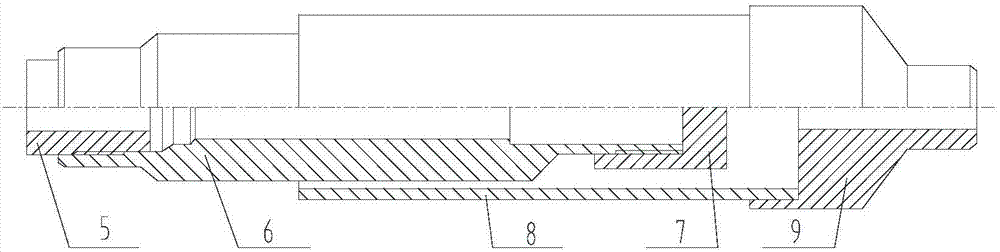

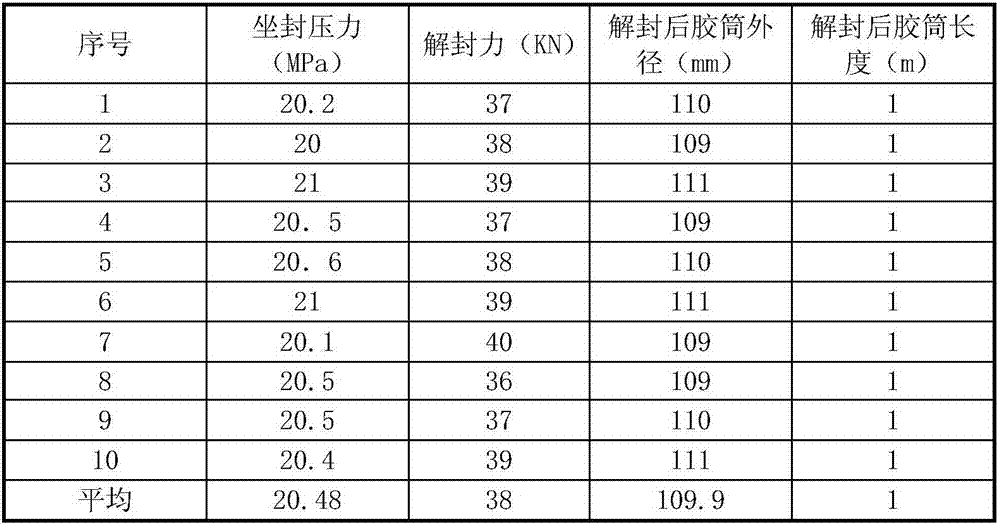

[0015] use as figure 2 The experimental device shown is to test the technical performance of the long rubber tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com