Full-automatic intelligent forming technology for paper matrixes

A molding process, fully automatic technology, applied in textiles and papermaking, etc., can solve the problems of unfavorable equipment absorbing paper molds, poor stability, high rigidity requirements, etc., to achieve the effect of improving equipment stability and mechanical precision, and reducing rigidity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

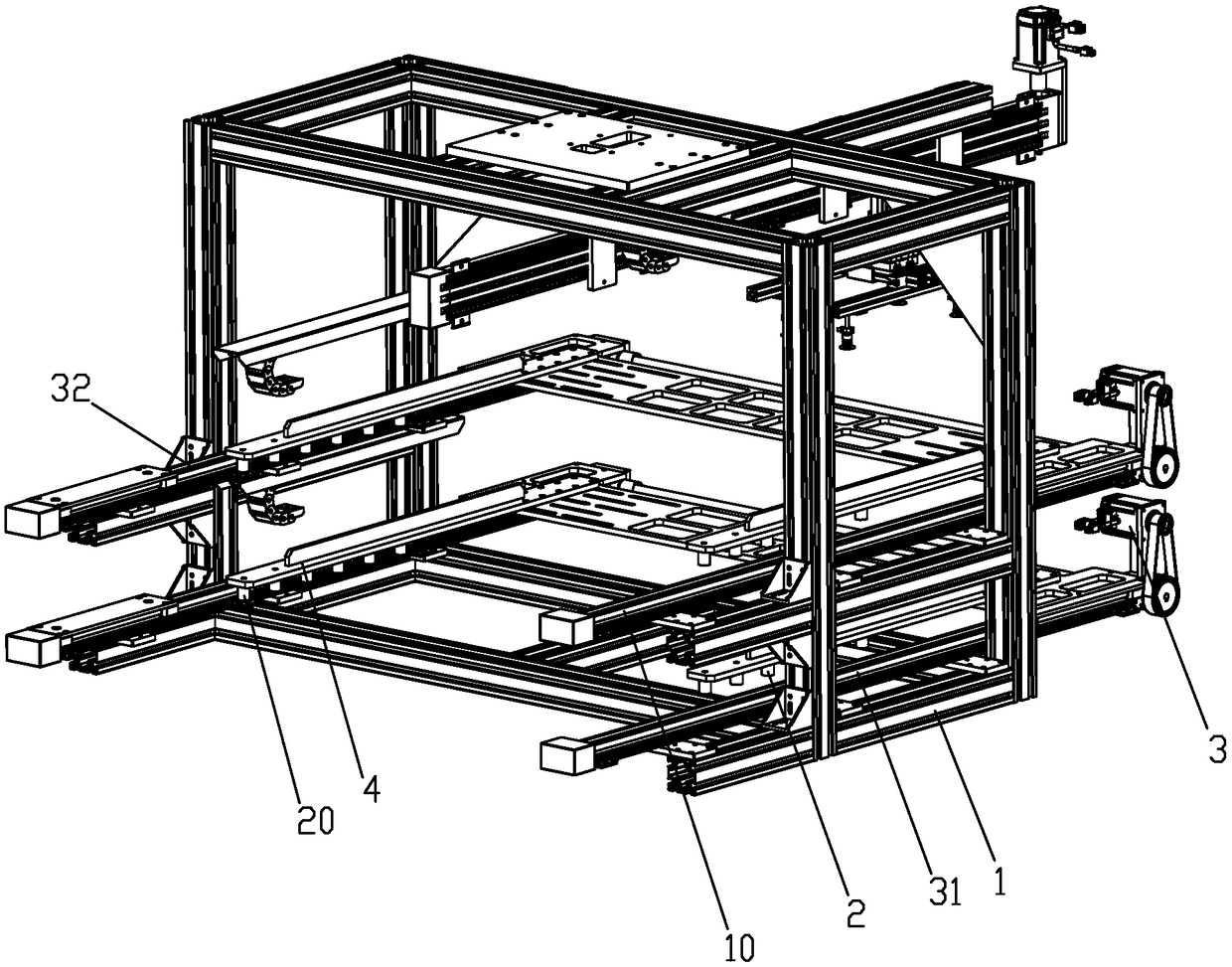

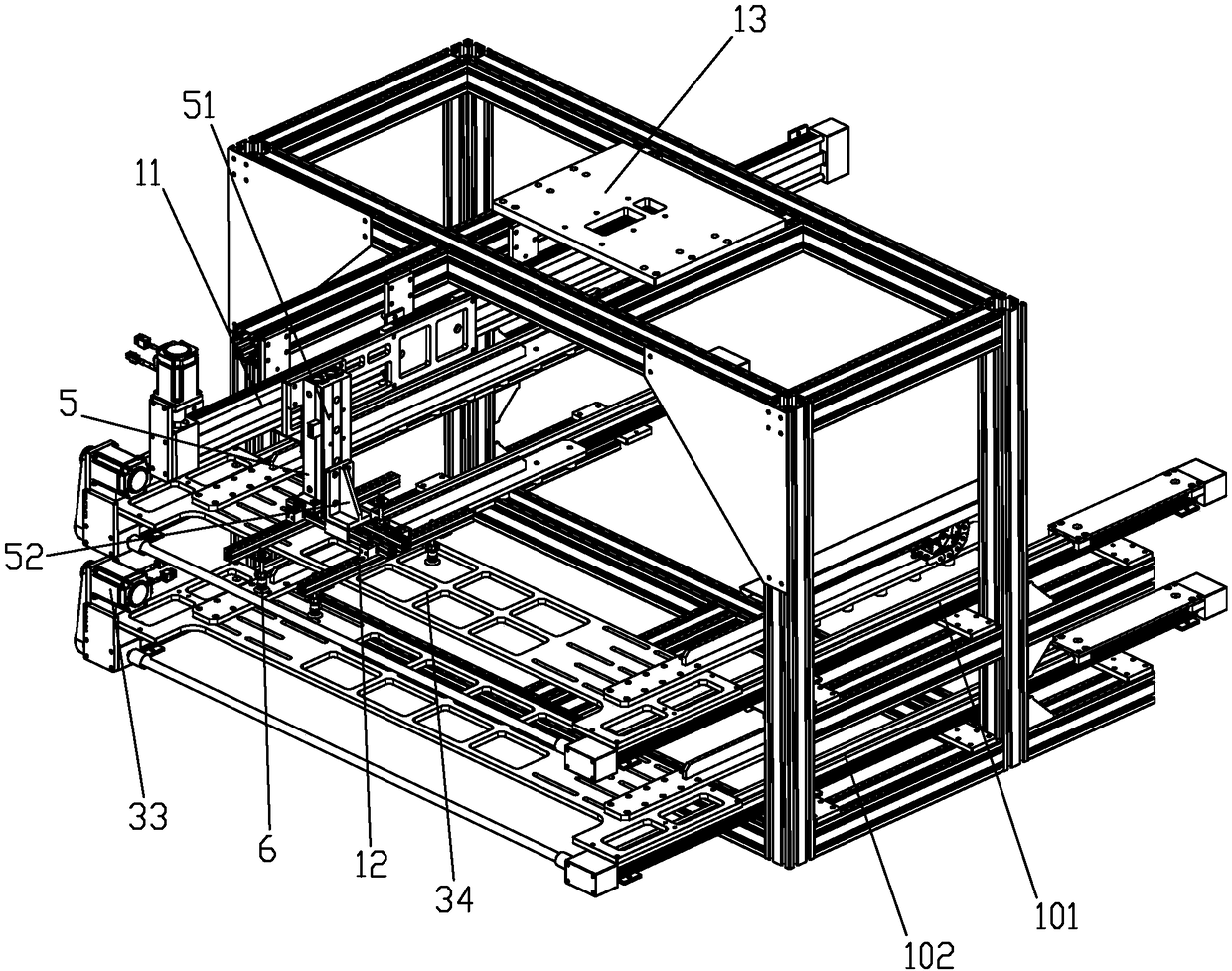

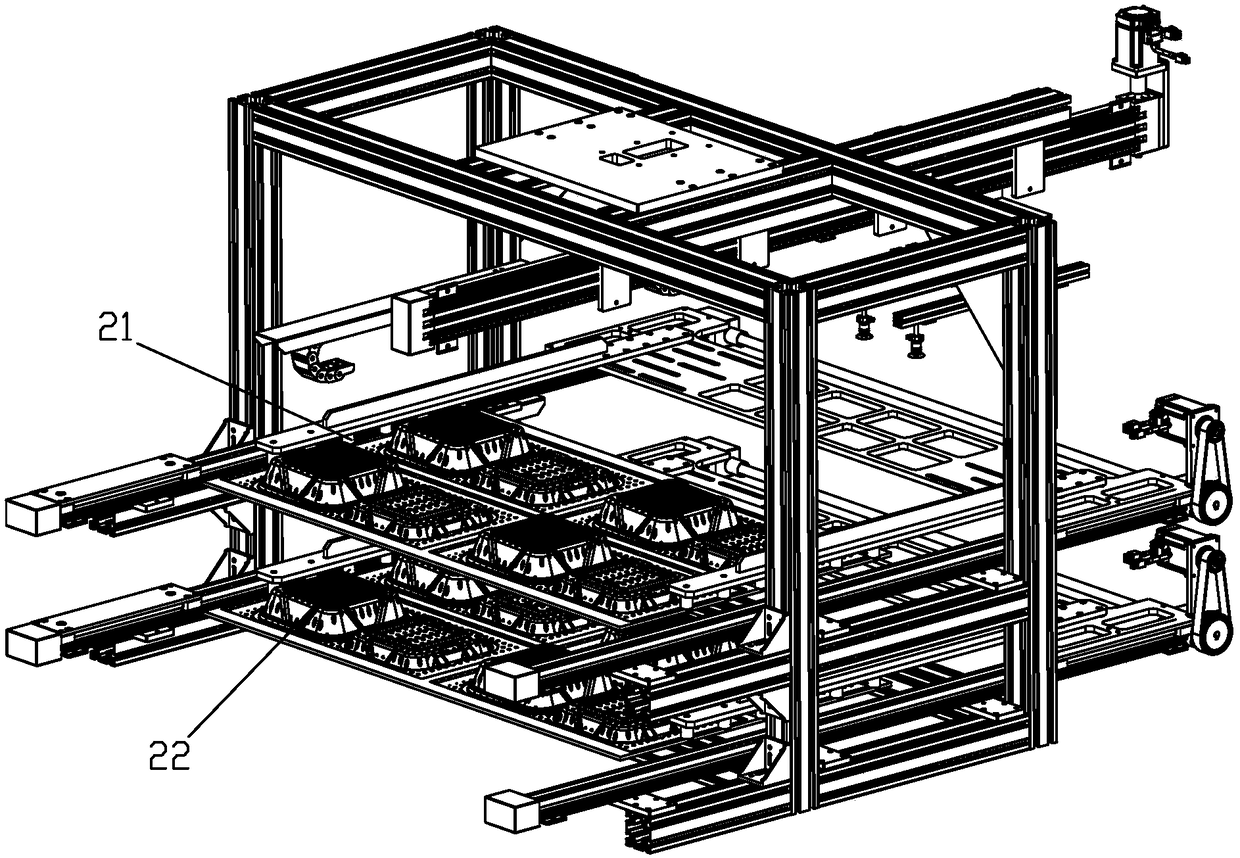

[0032] Please see attached figure 1 To attach Figure 5 , a kind of intelligent automatic transfer equipment of paper mold belt net, comprises frame 1, and described frame 1 is provided with longitudinal support 10, and described longitudinal support 10 is provided with longitudinal drive mechanism 3 and is driven by described longitudinal drive mechanism along the longitudinal support 10 A movable bar 4 that reciprocates longitudinally, and the movable bar 4 is provided with a paper mold suction device 2 that slides with the movable bar 4 to absorb the frame of the mesh surface carrying the paper mold. Specifically, the paper mold suction device 2 includes a plurality of electromagnets 20 disposed on the lower side of the movable strip 4 , and the plurality of electromagnets 20 are electrically connected to each other and arranged at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com