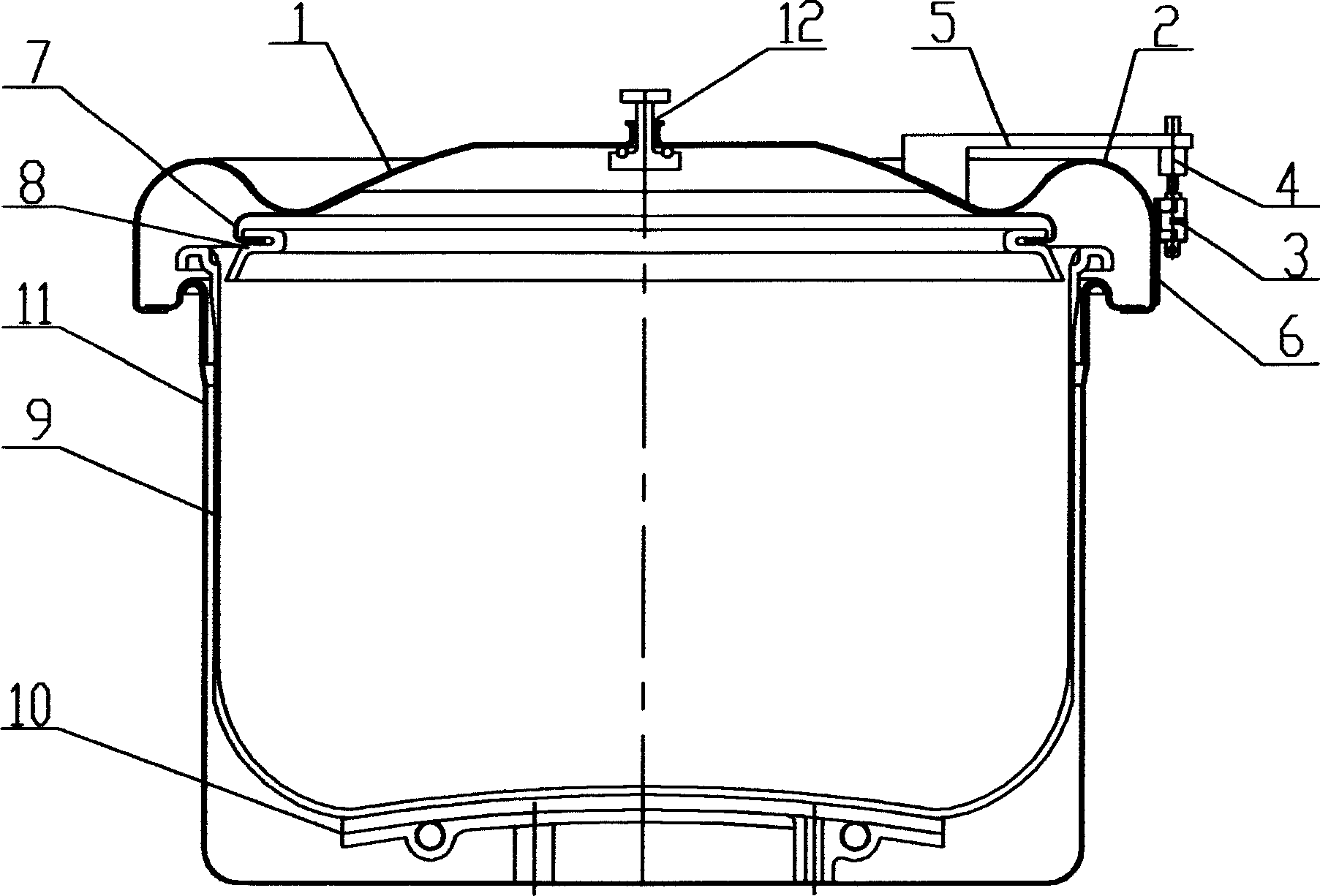

Moving-cover type electric pressure cooker

A moving-lid, electrical technology, applied in pressure cookers and other directions, can solve the problems of limited elastic displacement parameters of elastic elements, high material cost of the outer pot, increased process difficulty and complexity, etc., to ensure effectiveness, save material costs, and simplify The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

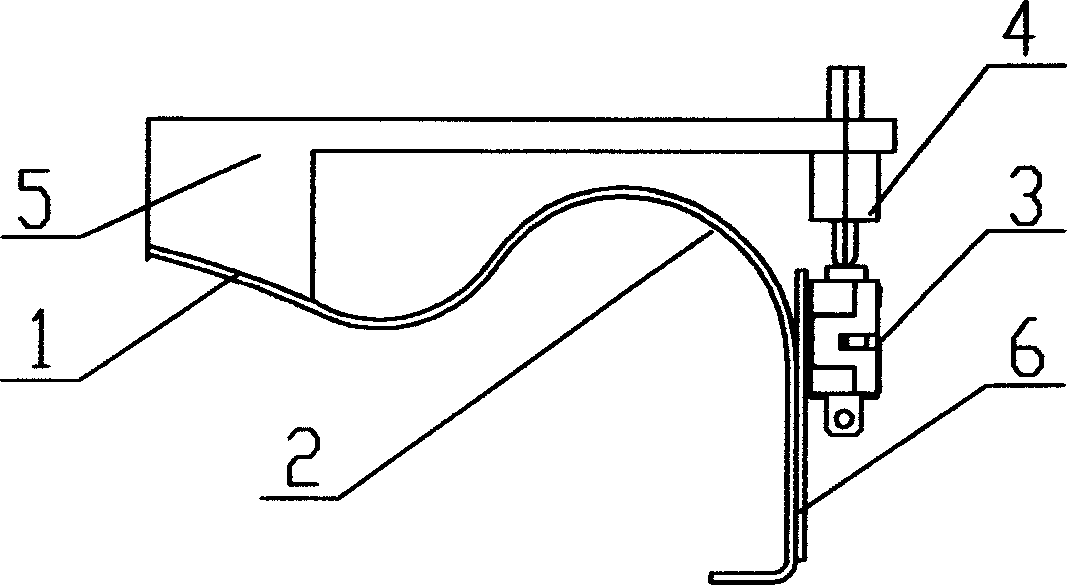

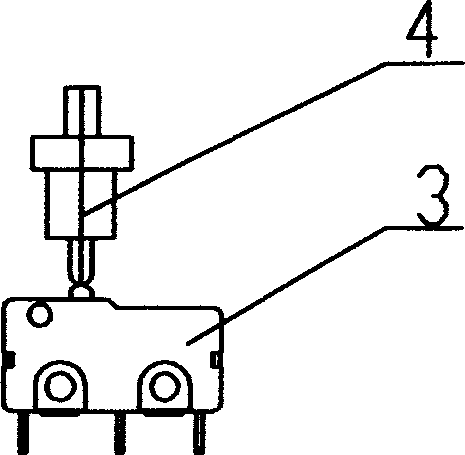

[0029] Embodiment: Take the caliber 20cm of the inner pot 9 as an example. Adopt the aluminum plate of thickness 2.5mm, inner pot 9 is stretched and formed, on the inner side of its pot edge, the top of sealing ring 8 sealing positions, along the circumference evenly arrange some pressure relief grooves (as 8). The size of each pressure relief groove is: the radial direction of the inner pot 9 is about 4mm, the arc in the circumferential direction is about 5°, and the height dimension (the dimension extending downward from the pot along the plane) is also the height dimension of the pressure relief ring line. It is directly related to the limit value of the maximum pressure in the pot, and should be designed in conjunction with the height of the sealing ring 8, the height of the sealing part of the pot cover 1, and the displacement of the elastic element 2 to obtain the required pressure relief value. The sealing ring 8 is made of high-quality silicon rubber, and its sealing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com