Friction stir welding repair method for threaded hole

A technology of friction stir welding and repair method, which is applied in the direction of welding equipment, non-electric welding equipment, manufacturing tools, etc., and can solve the problems of increased difficulty in the realization of threaded holes, greater influence of metallurgical bonding, and reduced efficiency of threaded hole repairs, etc. , to achieve the effect of improving repair efficiency, saving materials, and improving repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

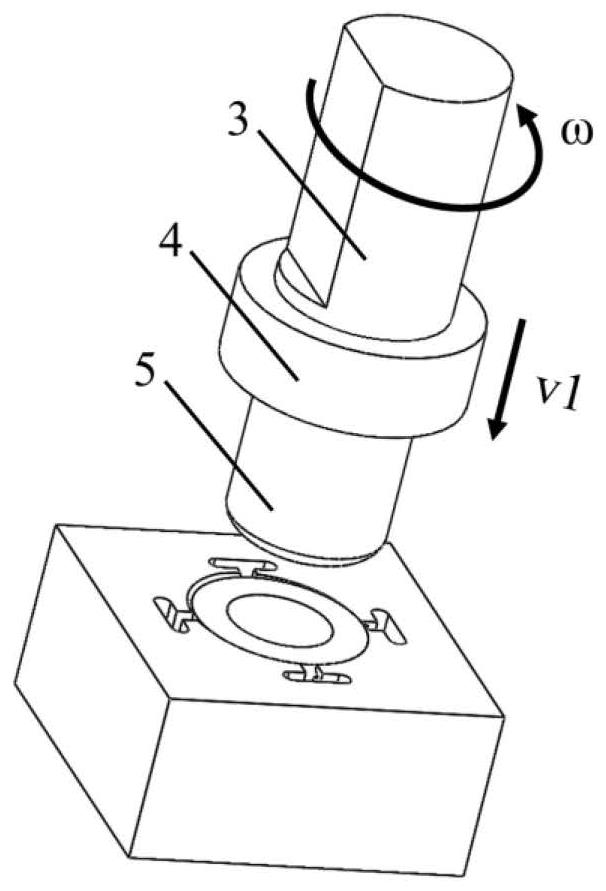

[0043] The present invention will be further described below in conjunction with drawings and embodiments.

[0044] The friction stir welding repair method for threaded holes provided by the present invention is suitable for repairing thread wear and missing defects in threaded holes. In this embodiment, the M8 threaded hole to be repaired with a depth of 12mm on a 7075 aluminum alloy component is used. As an example, the repair process includes the following steps:

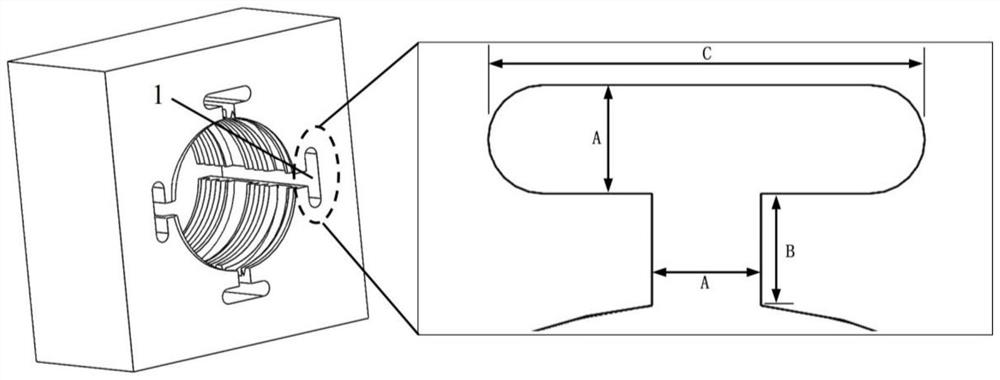

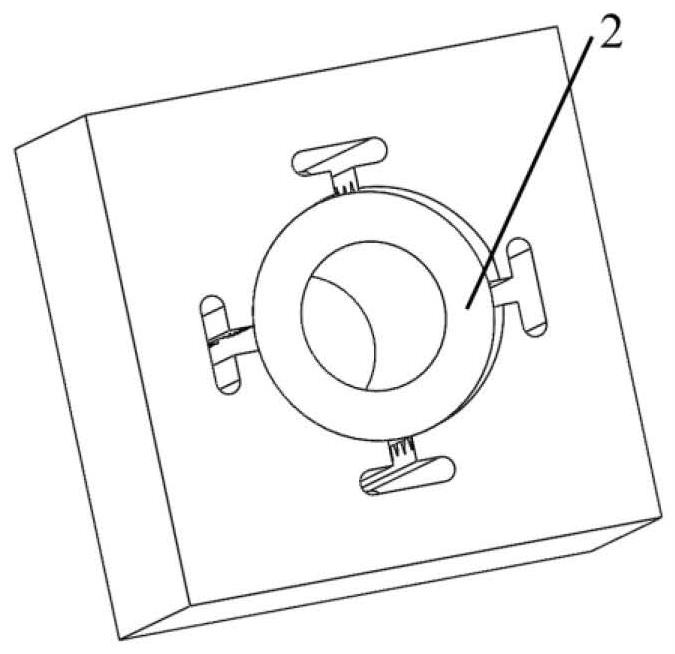

[0045] Step 1. Pretreatment of the threaded hole to be repaired

[0046] Fix the 7075 aluminum alloy component with the threaded hole to be repaired on the milling machine, use the milling cutter to uniformly process four T-shaped slots 1 of the same size along the circumference of the threaded hole to be repaired, and each T-shaped slot extends along the height direction of the threaded hole to be repaired ,Such as figure 1 As shown; the size of T-slot 1: A is 3mm, B is 3mm, and C is 6mm; after the T-slot is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com