Wrought superalloy and stainless steel gas compressor rotor blade tip repair method and tool

A technology for deforming high-temperature alloys and compressor rotors, which is applied in the coating process and coating of metal materials, can solve the problems of interference in the process of equipment, difficulty in clamping and positioning of parts, etc., so as to improve repair efficiency and quality The effect of small amount and fine grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0049] EOS M290 laser selective melting (SLM) equipment was used to repair the wear damage of the blade tip of a certain type of engine GH4169G deformed superalloy compressor blade. The specific steps are as follows:

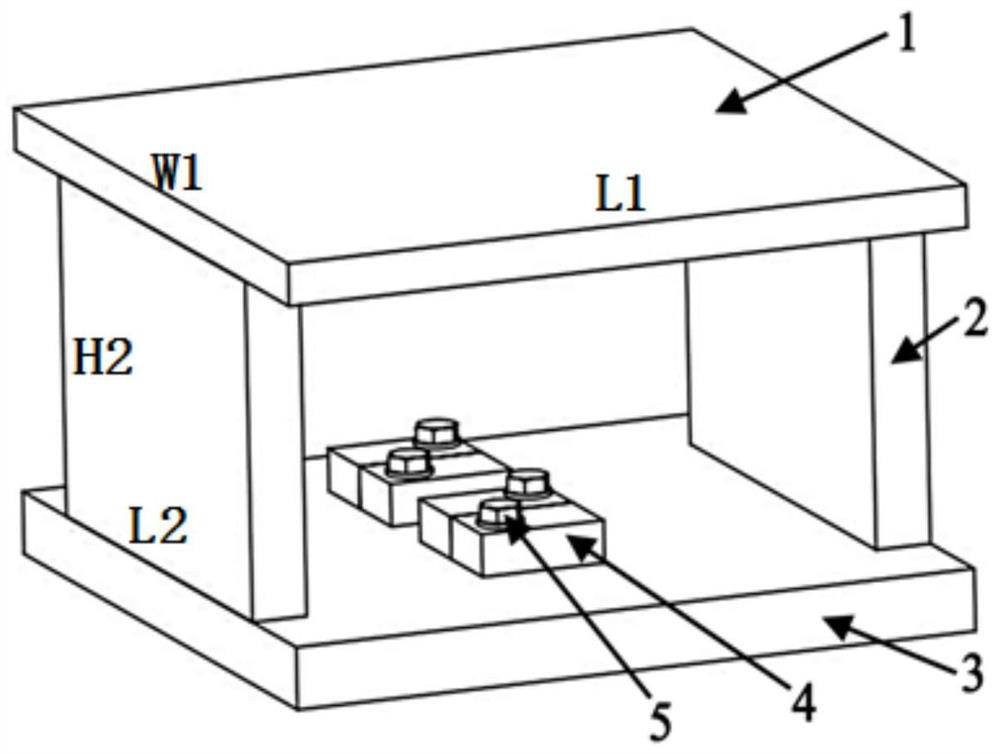

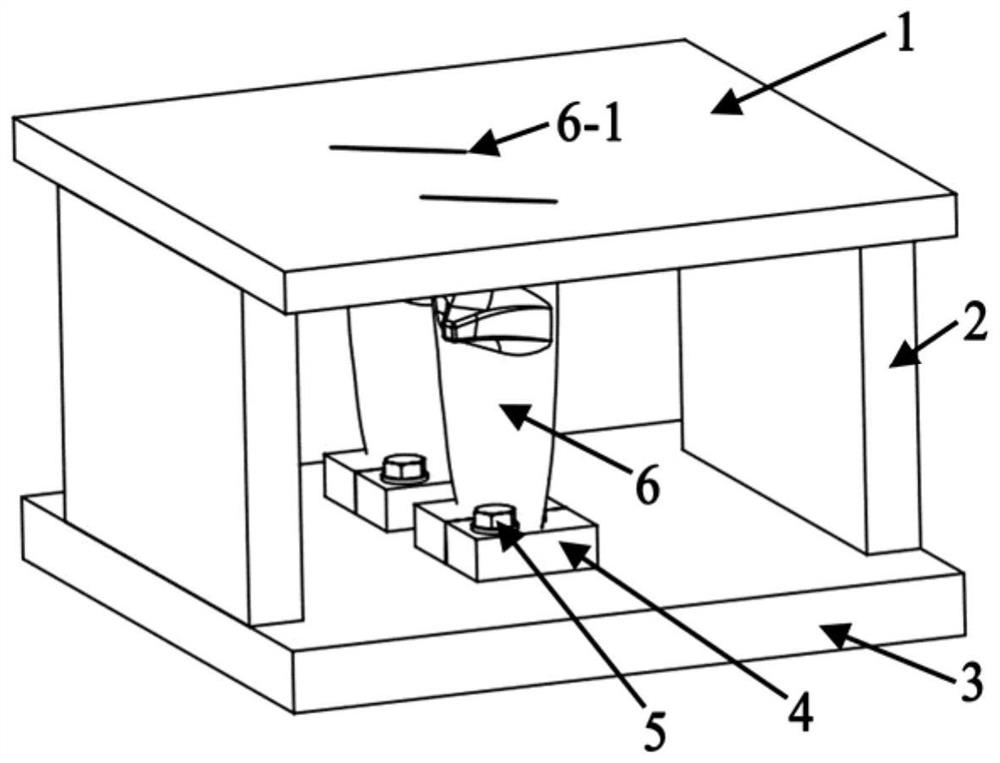

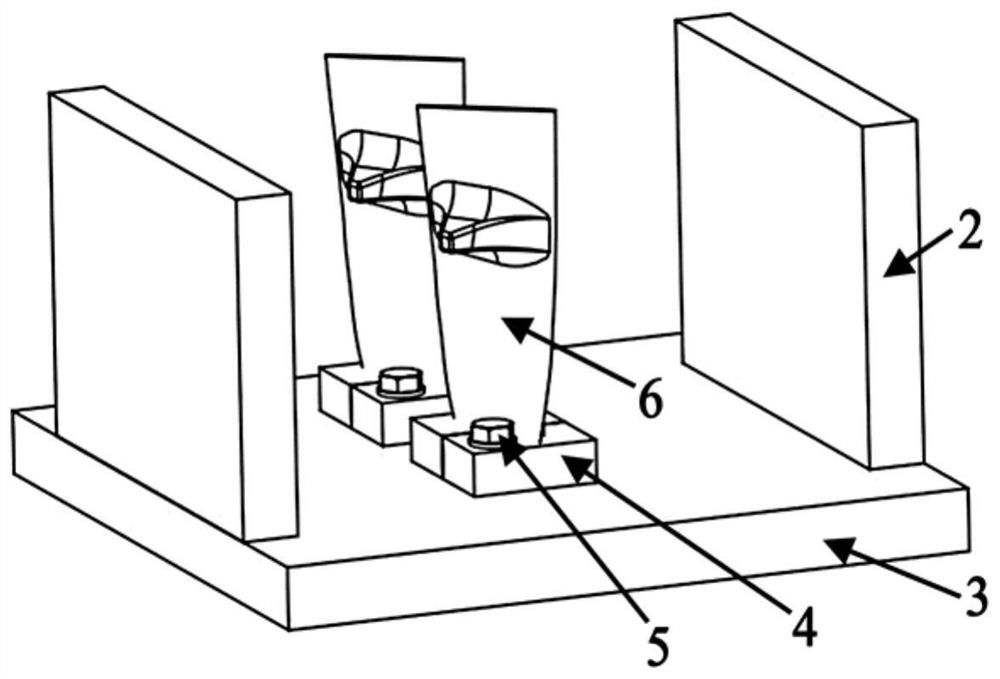

[0050] S1. Tooling design and blade clamping: Design a tooling to assist compressor blade positioning, clamping and laser selective melting (SLM) repair. For the designed tooling shape and clamping method, see Figure 1 ~ Figure 3 .

[0051] see Figure 1 to Figure 5 , The tooling designed in the present invention includes an upper base plate 1 , a support plate 2 , a lower base plate 3 , locking blocks 4 and bolts 5 .

[0052] The size of the upper base plate 1 is 252mm (length) × 252mm (width) × 10mm (thickness), and a through hole with the same size and shape as the blade tip is provided at the blade installation position, see figure 1 with figure 2 ;

[0053] The size of the support plate 2 is 252mm (height) × 200mm (length) × 5mm (thickness), which is...

specific example 2

[0070] Arcam A2X Electron Beam Selective Melting (EBM) equipment was used to repair the wear damage of the blade tip of a 2Cr13 stainless steel compressor blade of a certain type of engine. The specific steps are as follows:

[0071] S1. Tool design and blade clamping: Design a tool to assist blade positioning, clamping and electron beam melting (EBM) repair. For the designed tooling shape and clamping method, see Figure 1 ~ Figure 3 .

[0072] see Figure 1 to Figure 5 , The tooling designed in the present invention includes an upper base plate 1 , a support plate 2 , a lower base plate 3 , locking blocks 4 and bolts 5 .

[0073] The size of the upper base plate 1 is 252mm (length) × 252mm (width) × 12mm (thickness), and a through hole with the same size and shape as the tip of the blade is provided at the blade installation position, see figure 1 with figure 2 ;

[0074] The size of the support plate 2 is 252mm (height) × 210mm (length) × 6mm (thickness), which is use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com