Coreless stepping motor and control method thereof

A stepping motor, ironless technology, applied in control system, motor generator control, magnetic circuit shape/style/structure, etc., can solve large inductance and cogging torque, reduce stepping angle precision of stepping motor Insufficient speed, insufficient motor bandwidth, etc., to overcome the positioning torque or stall torque, and reduce the effect of ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

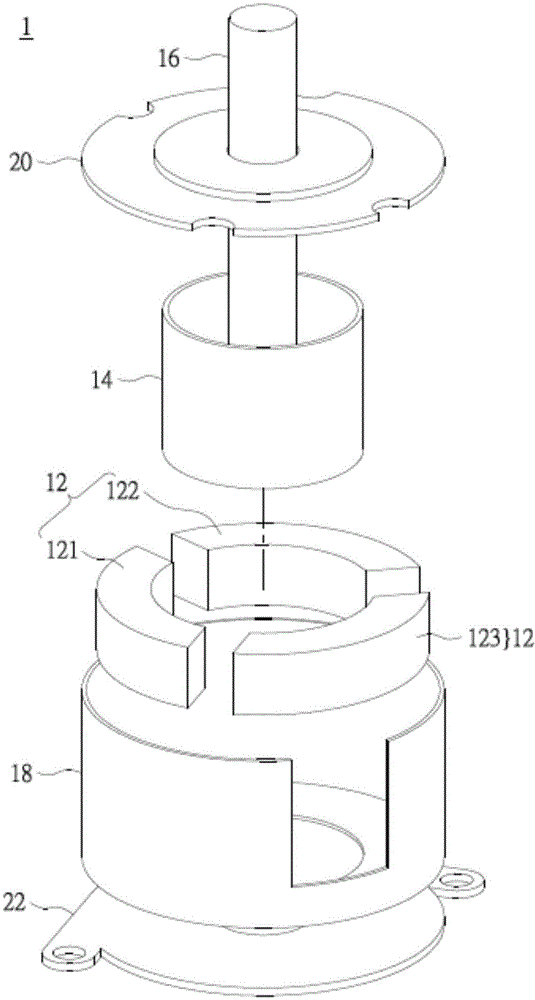

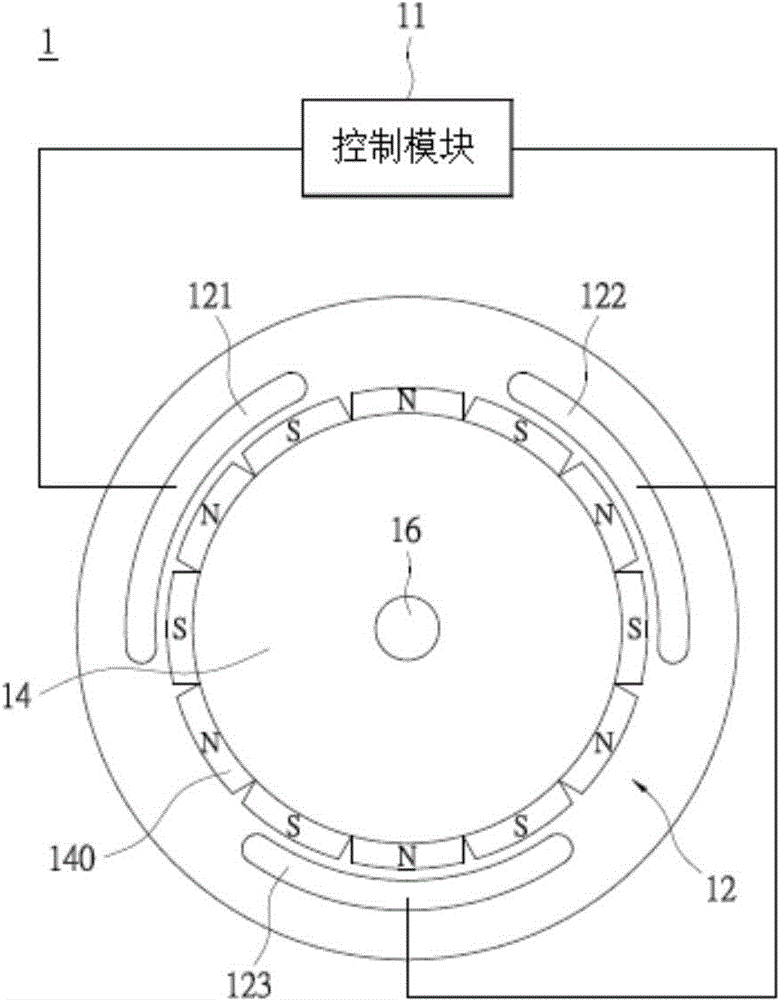

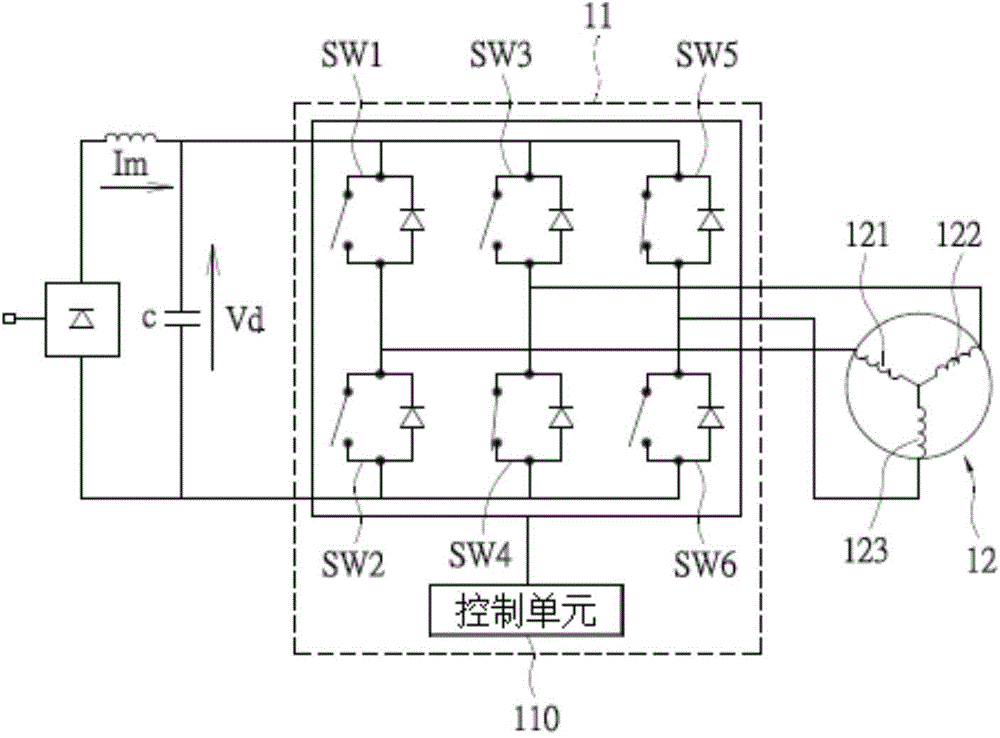

[0072] figure 1 It is an exploded structure diagram of an iron-core stepping motor according to an embodiment of the present invention. Figure 2A It is a schematic cross-sectional view of an iron-less stepping motor according to another embodiment of the present invention. Figure 2B based on Figure 2A A schematic diagram of a control module of an ironless stepping motor according to another embodiment of the present invention. see figure 1 , Figure 2A and Figure 2B . An iron-core stepping motor 1 is suitable for a servo machine. The iron-less stepping motor 1 includes: a stator group 12, a rotor group 14, a pivot 16, a housing 18, a cover 20, A board body 22 and a control module 11 . Actually, the casing 18 is used to accommodate the stator set 12 and the rotor set 14 . The pivot 16 is pivotally connected to the rotor set 14 , and the pivot 16 is disposed on the same axis of the stator set 12 and the rotor set 14 . The cover body 20 and the board body 22 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com