Mobile semiconductor laser mould repairing system

A laser repair and semiconductor technology, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of inconvenient movement and bulky laser repair device, and achieve the effect of eliminating time-consuming and laborious work, shortening repair time, and realizing repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

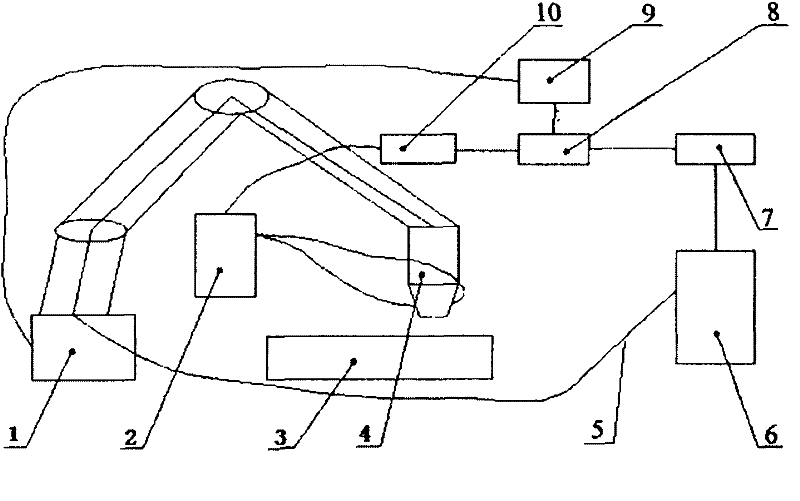

[0011] In conjunction with the accompanying drawings, the specific implementation process is as follows:

[0012] 1) Before the laser repair starts, the damaged part of the workpiece 3 is firstly preprocessed, and the three-dimensional solid model of the damaged part is scanned and extracted;

[0013] 2) The CAD model is layered by layering software to obtain the STL file;

[0014] 3) Input material thermophysical parameters, environmental parameters and other data related to process parameter design into the system, and then generate the processing path and CNC code of each layer according to the STL file;

[0015] 4) The computer 8 sends powder feeding instructions to the powder feeding controller 10 to control the opening of the powder feeder 2 and its powder feeding rate; sends power instructions to the laser controller 7 to control the opening of the semiconductor laser 6 and its power output; The device 9 transmits speed commands to control the scanning path and scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com