Continuous casting machine roller array curve design device and method

A curve design and continuous casting machine technology, applied in the field of metallurgy, can solve the problems of high installation accuracy, unguaranteed, and reduced roller force, etc., to achieve the effect of overcoming large force, good practical effect, and overcoming installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

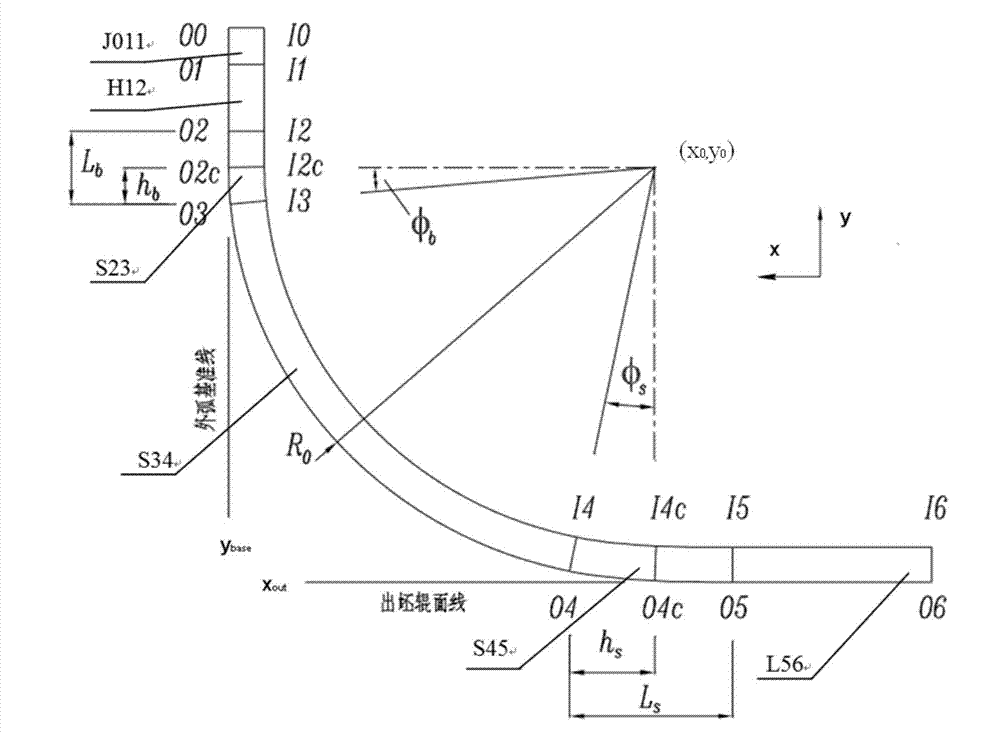

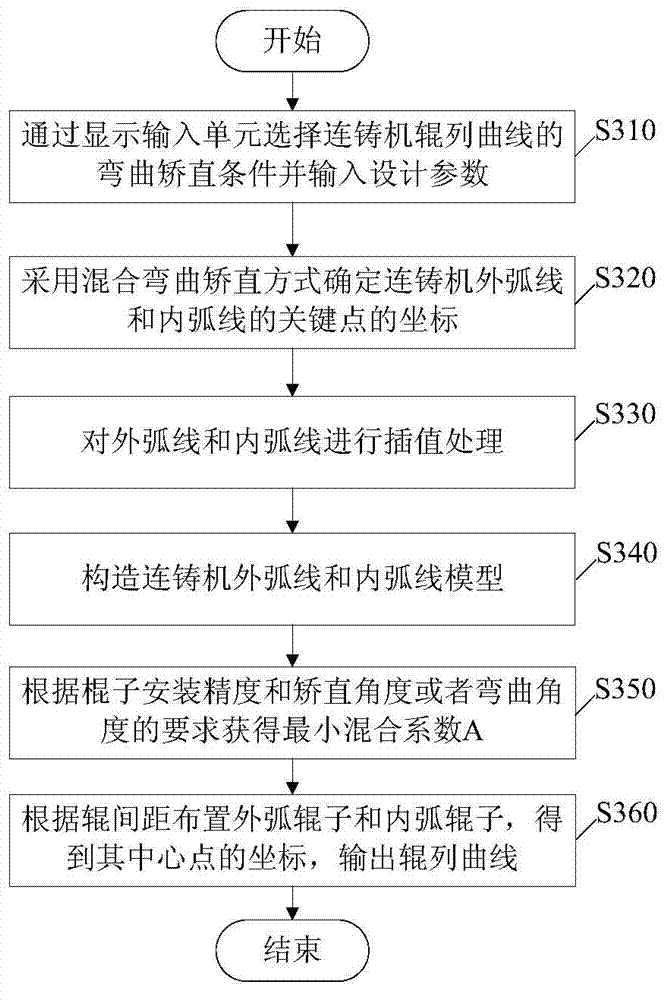

[0033] figure 1 It is a schematic diagram of the outer arc and inner arc of the straight arc continuous casting machine. The roll row curve of the continuous casting machine includes inner arcs and outer arcs parallel to each other. The arc is obtained by interpolation in the normal direction, so the design of the outer arc is particularly important. As shown in the figure, the outer arc of the continuous casting machine is composed of the mold section J01, the vertical section H12, the bending section S23, the basic arc section S34, the straightening section A curve smoothly connected by the straight section S45 and the horizontal section L56. in,

[0034] The starting point and ending point of the crystallizer section J01 are O0 and O1, O0 is the outer edge point of the upper mouth of the mold of the continuous casting machine, and O1 is the outer edge point of the lower mouth of the mold;

[0035] The starting point and ending point of the vertical segment H12 are O1 and ...

no. 2 example

[0120] The roll row curve of the full-arc continuous casting machine designed by the method of mixed bending and straightening is similar to that of the straight-arc continuous casting machine. Figure 6 It is a schematic diagram of the outer arc and inner arc of the full arc continuous casting machine. As shown in the figure, the outer arc and inner arc of the full arc continuous casting machine are similar to the straight arc continuous casting machine, but the full arc continuous casting The outer arc and inner arc of the casting machine do not include the vertical section and the curved section. Taking the outer arc of the full-arc continuous casting machine as an example, it is the mold section J01, the basic arc section S14, the straightening section S45, A curve smoothly connected by the horizontal segment L56, where,

[0121] The starting point and ending point of the crystallizer section J01 are O0 and O1, O0 is the outer edge point of the upper mouth of the mold of t...

no. 3 example

[0140] The design parameters of a slab straight arc continuous casting machine are as follows:

[0141] Billet section = 1.6x 0.22m2

[0142] Pulling speed=0.7m / min

[0143] Basic radius = 10.0m

[0144] Horizontal section length = 12.23m

[0145] Vertical section height = 2.39m

[0146] Crystallizer height = 0.9m

[0147] Casting machine length = 29.43m

[0148] Datum arc origin (x 0 ,y 0 )=14.0,15.5(m,m)

[0149] Number of straightening points = 12

[0150] Bending conditions and straightening conditions:

[0151] Bending section length = 1.86m

[0152] Straightening section length = 3.67m

[0153] Take the end point O5 of the straightening section as the origin and adopt the continuous straightening method in the prior art to obtain the coordinates of each point in the straightening section of the continuous casting machine as shown in Table 1

[0154] Table 1

[0155]

[0156] According to the invention patent application 201310565711.9 of the applicant, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com