A rotary traction device for an injection molding machine

A pulling device and injection molding machine technology, applied in the field of injection molding, can solve the problems of uneven film roll thickness, uneven film tube wall thickness, affecting film flatness and coiling quality, etc., so as to improve the flatness and coiling quality, Reduced offset and wrinkling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

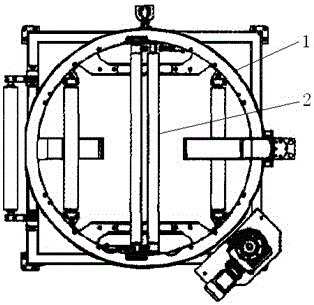

[0016] see Figure 1-Figure 2 , the embodiment of the present invention includes:

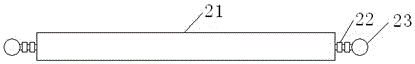

[0017] A rotary traction device for an injection molding machine, comprising a number of rotating guide rollers 2 movably connected in an annular bracket 1, the rotating guide rollers comprising a roller body 21, connecting rods 22 connected to both ends of the roller body 21, and The rolling element 23 installed on the head of the connecting rod 22 is a hollow structure capable of bending freely.

[0018] There are two rotating guide rollers 2, which are stacked and rotatably connected in the circular bracket 1 up and down. It can maintain precise position, improve strength and rigidity, and has high stability...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com