Substrate processing method and substrate processing apparatus

A technology for a substrate processing device and a substrate processing method, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as metal film damage, achieve cost reduction, fully clean functions, and ensure cleaning The effect of the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

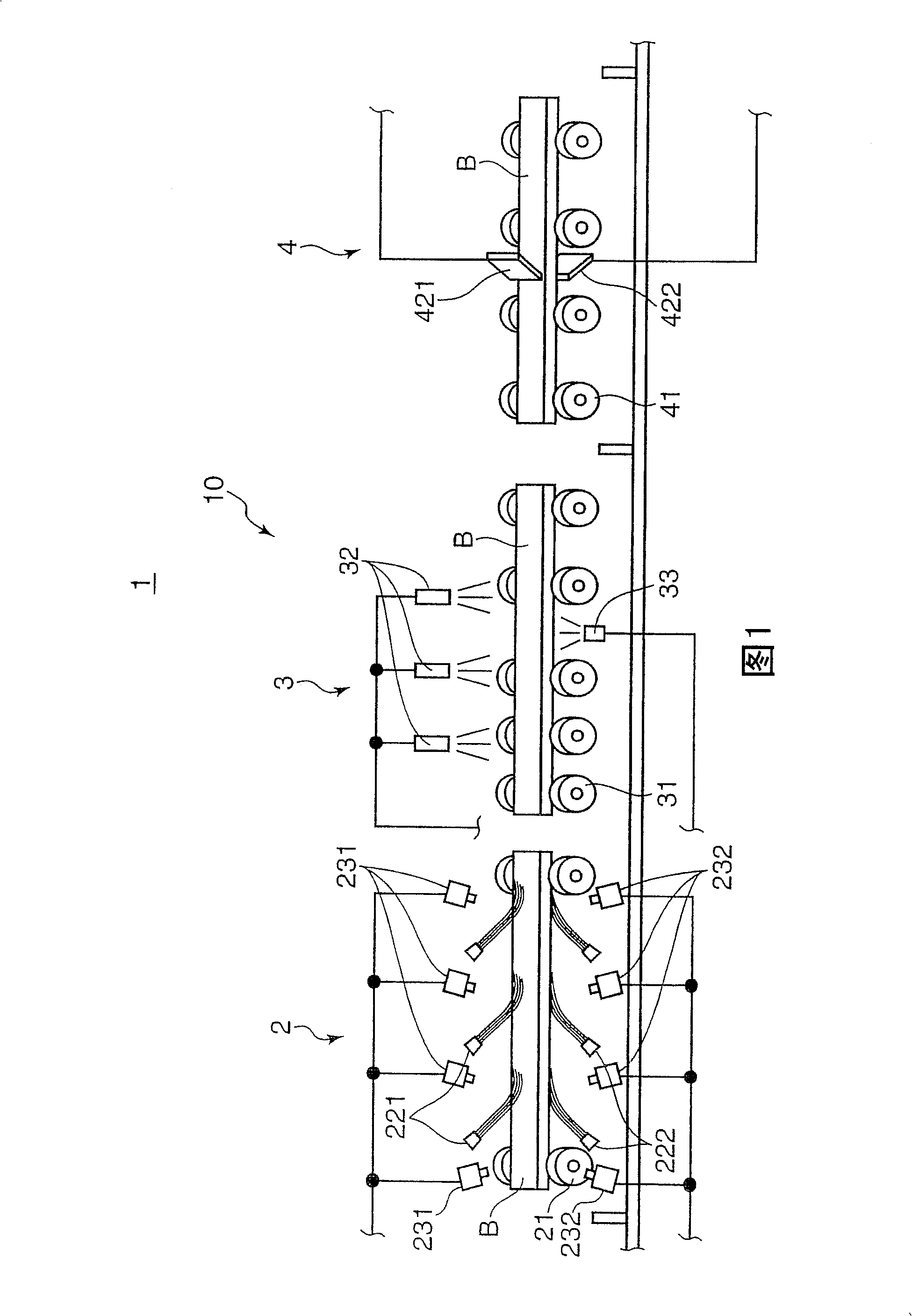

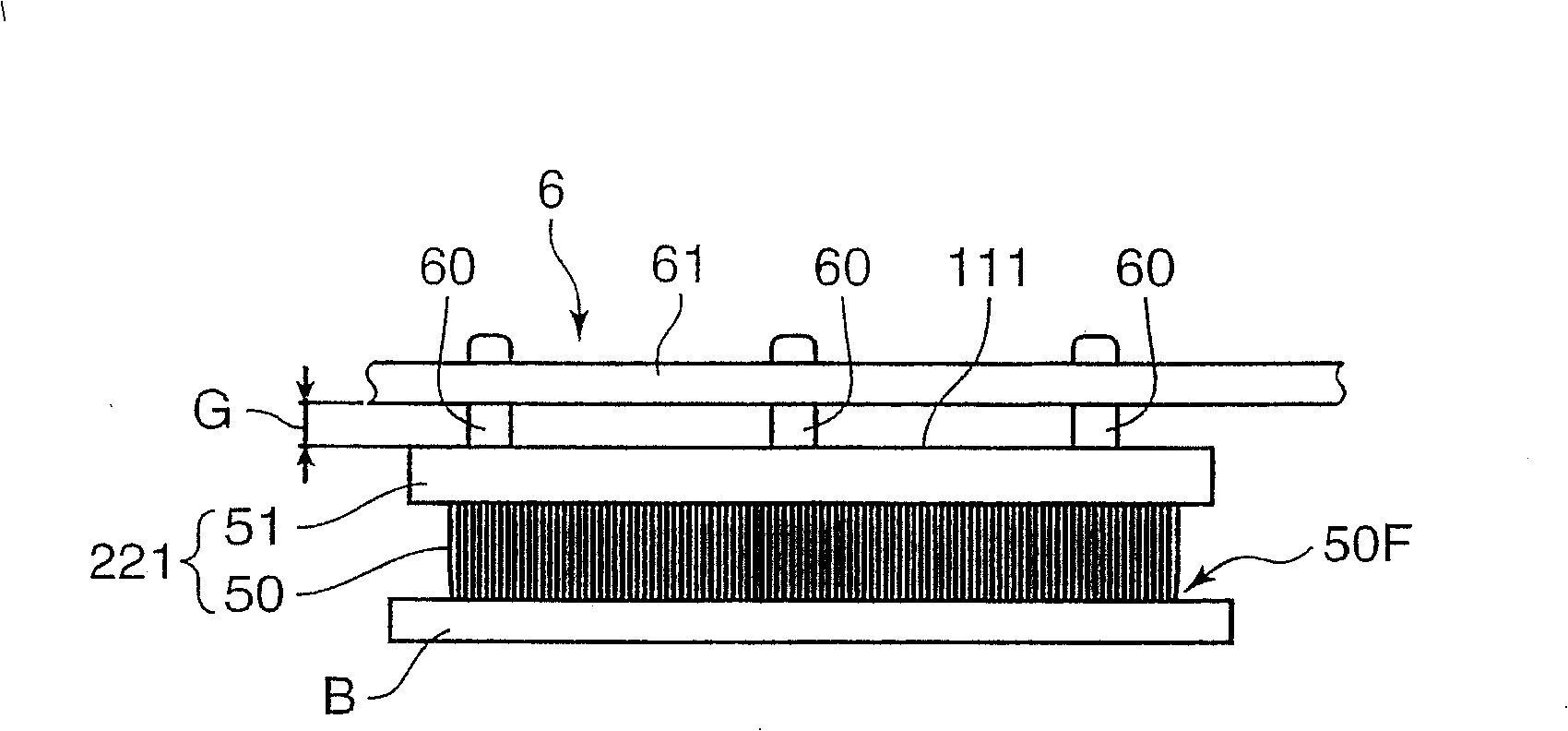

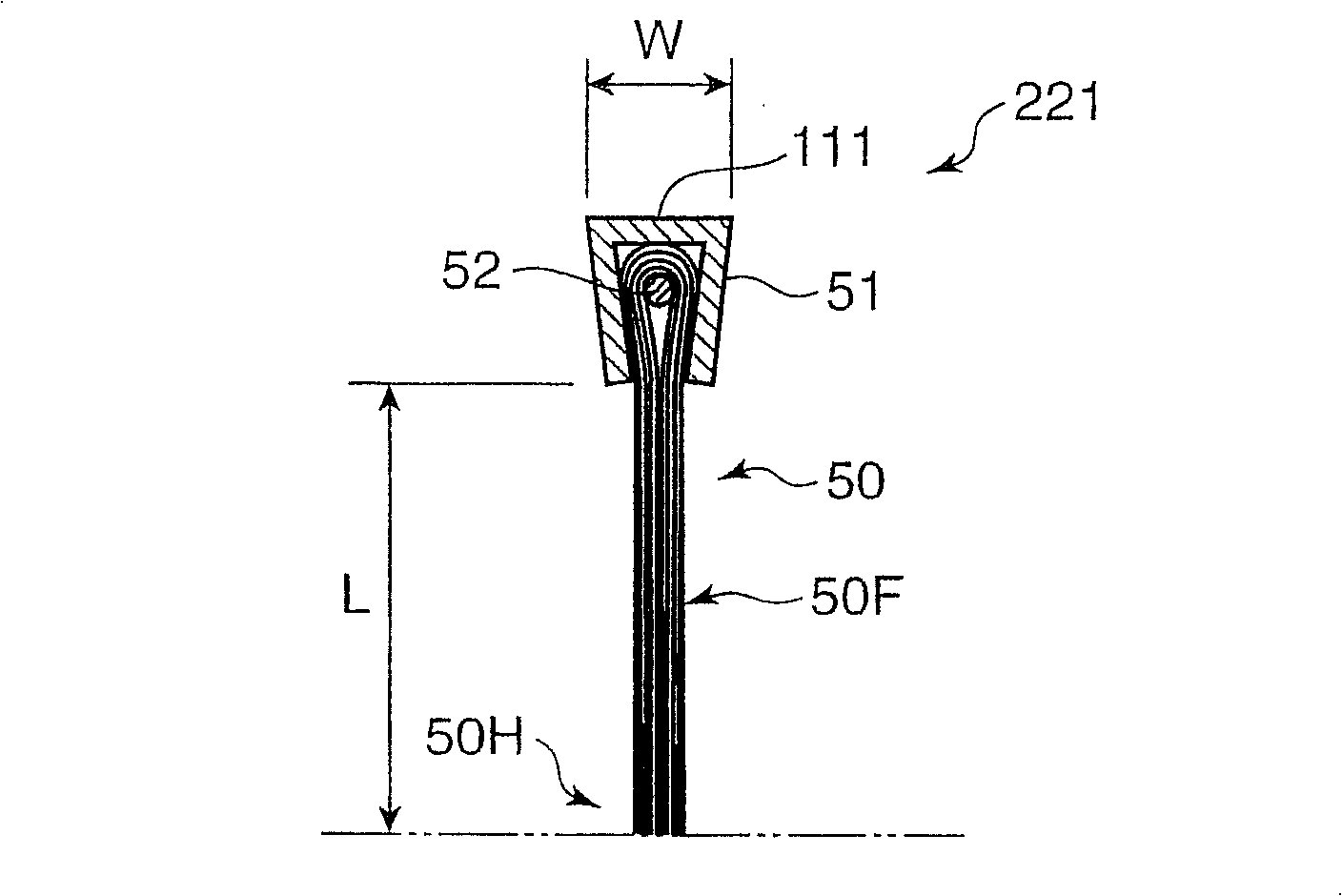

[0040] Hereinafter, a substrate processing apparatus and a substrate processing method according to an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a diagram schematically showing a substrate cleaning device included in a substrate processing device according to an embodiment of the present invention. The substrate processing apparatus 1 has a substrate cleaning apparatus 10 . The substrate cleaning apparatus 10 includes: a brush cleaning chamber 2 for performing chemical liquid treatment on a substrate B to be processed; a rinse chamber 3 for rinsing a substrate B passing through the brush cleaning chamber 2 ; and an air knife chamber 4 . In addition, in the substrate cleaning apparatus 10 , it is preferable to transport the substrate B in a posture inclined from a horizontal direction perpendicular to the transport direction of the substrate B. As shown in FIG. By conveying the substrate B in this posture, various liquids s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com