Patents

Literature

37 results about "Systematic deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for detecting insider threats

ActiveUS20150101053A1Memory loss protectionError detection/correctionSystematic deviationMachine learning

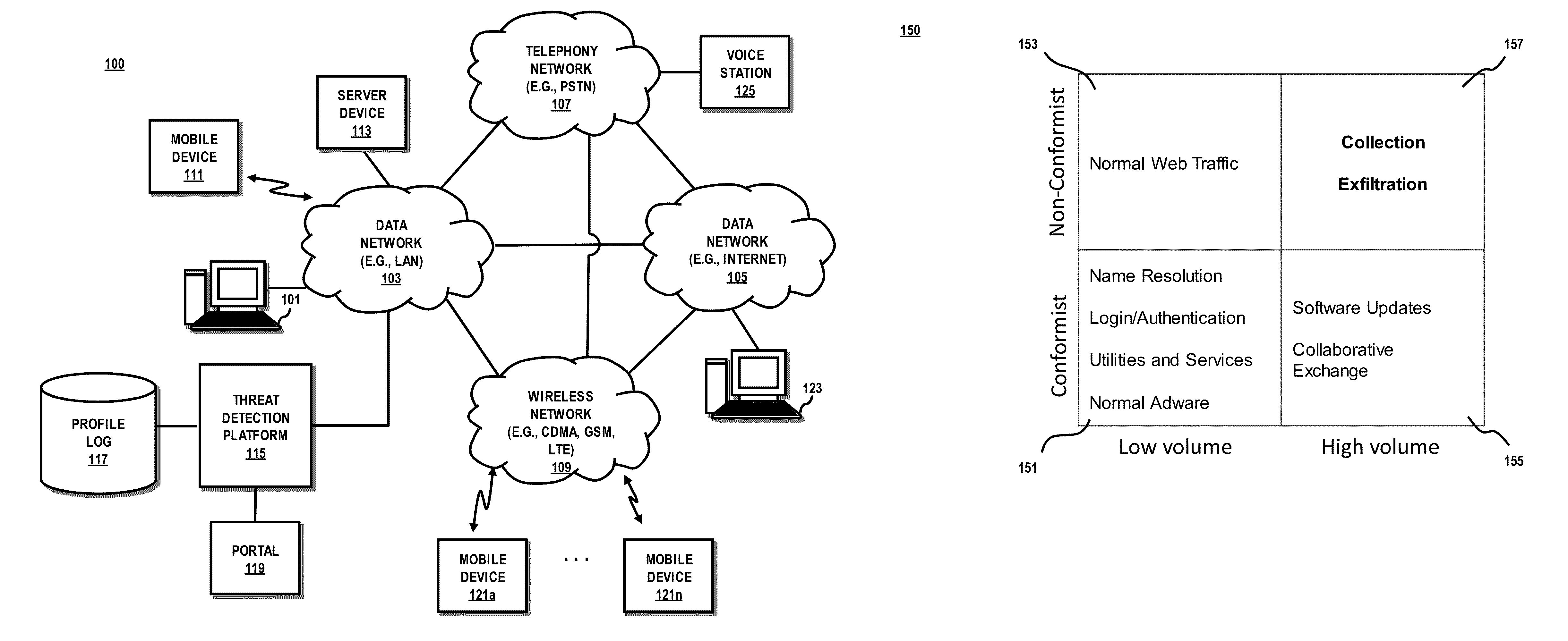

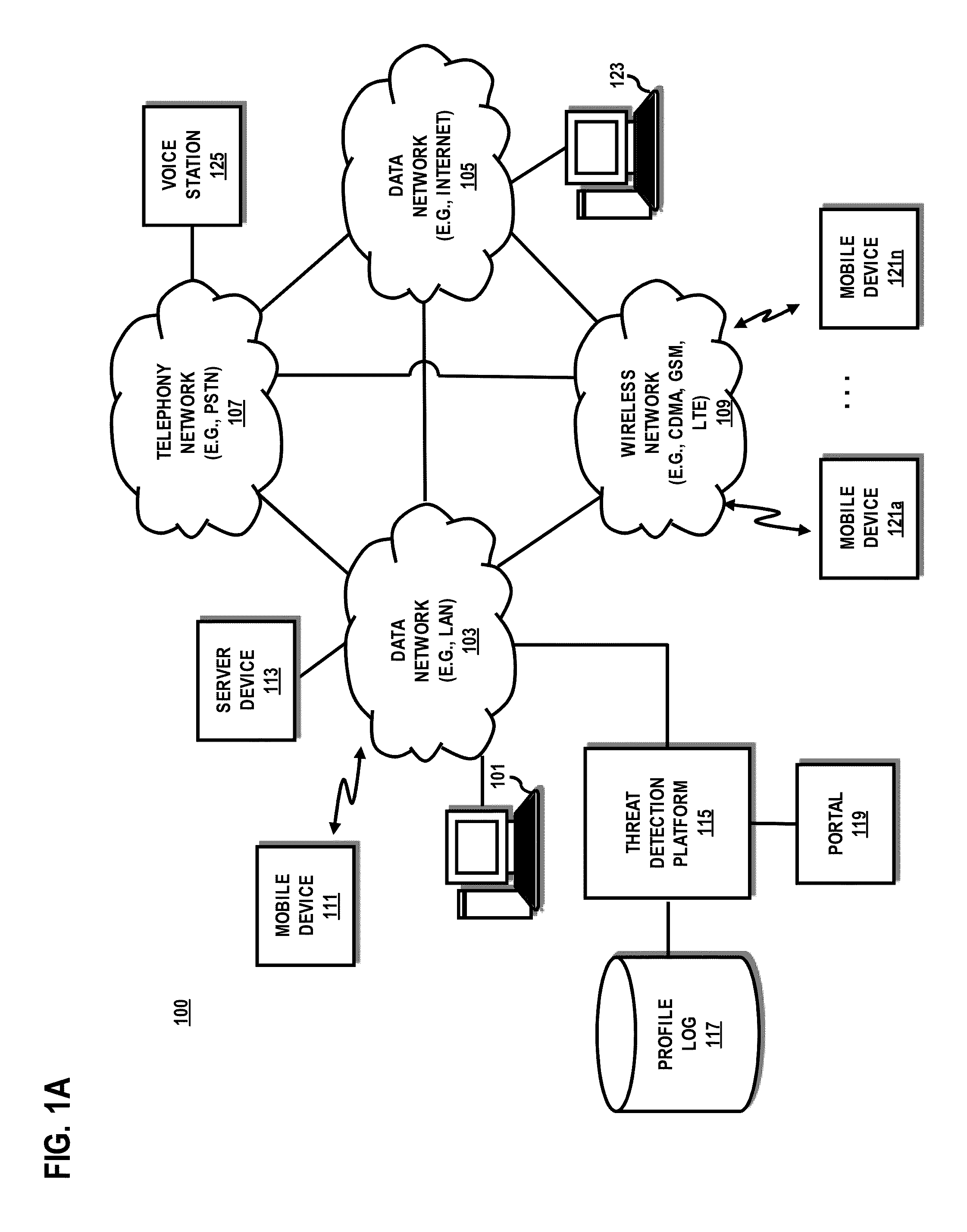

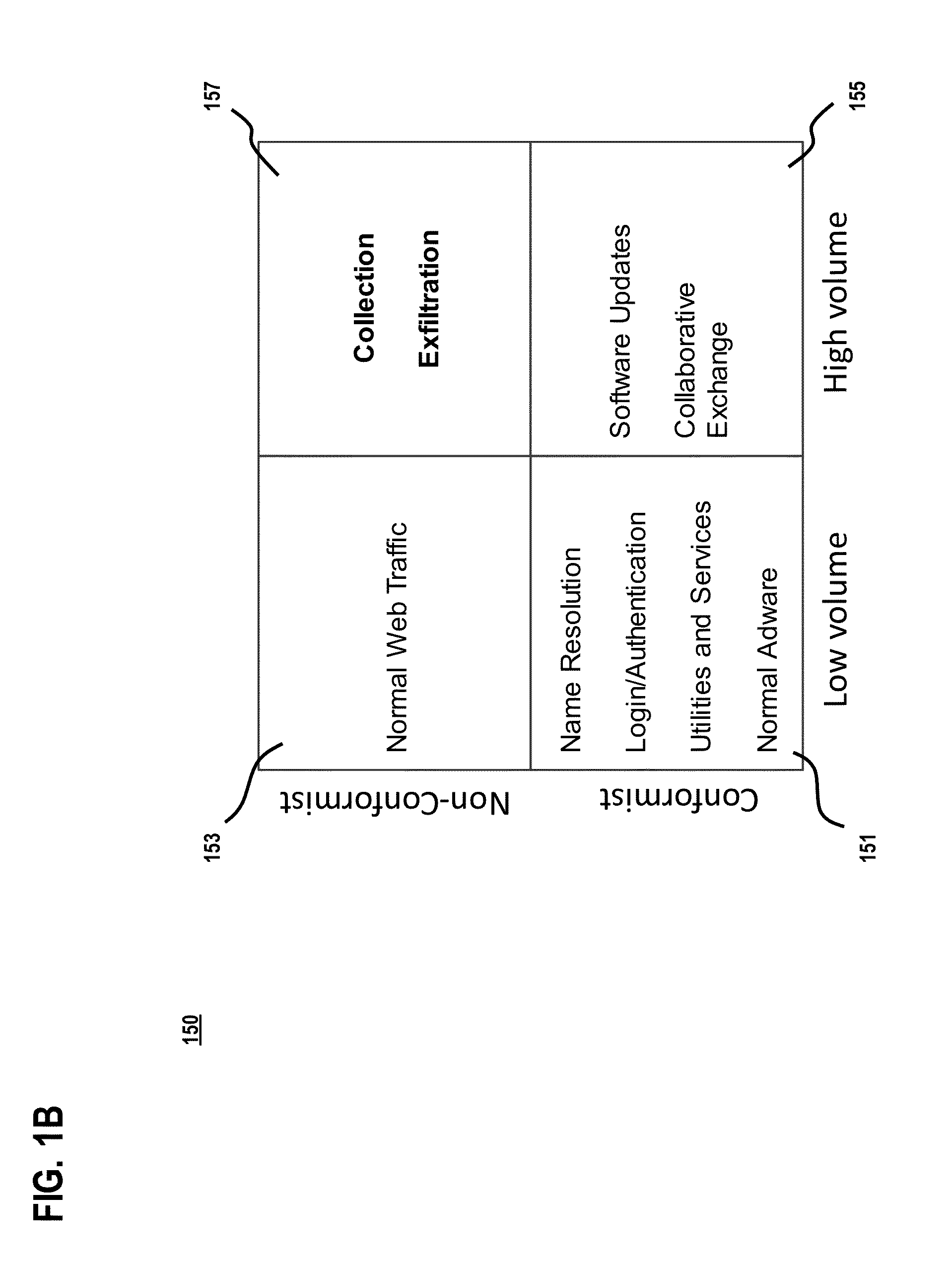

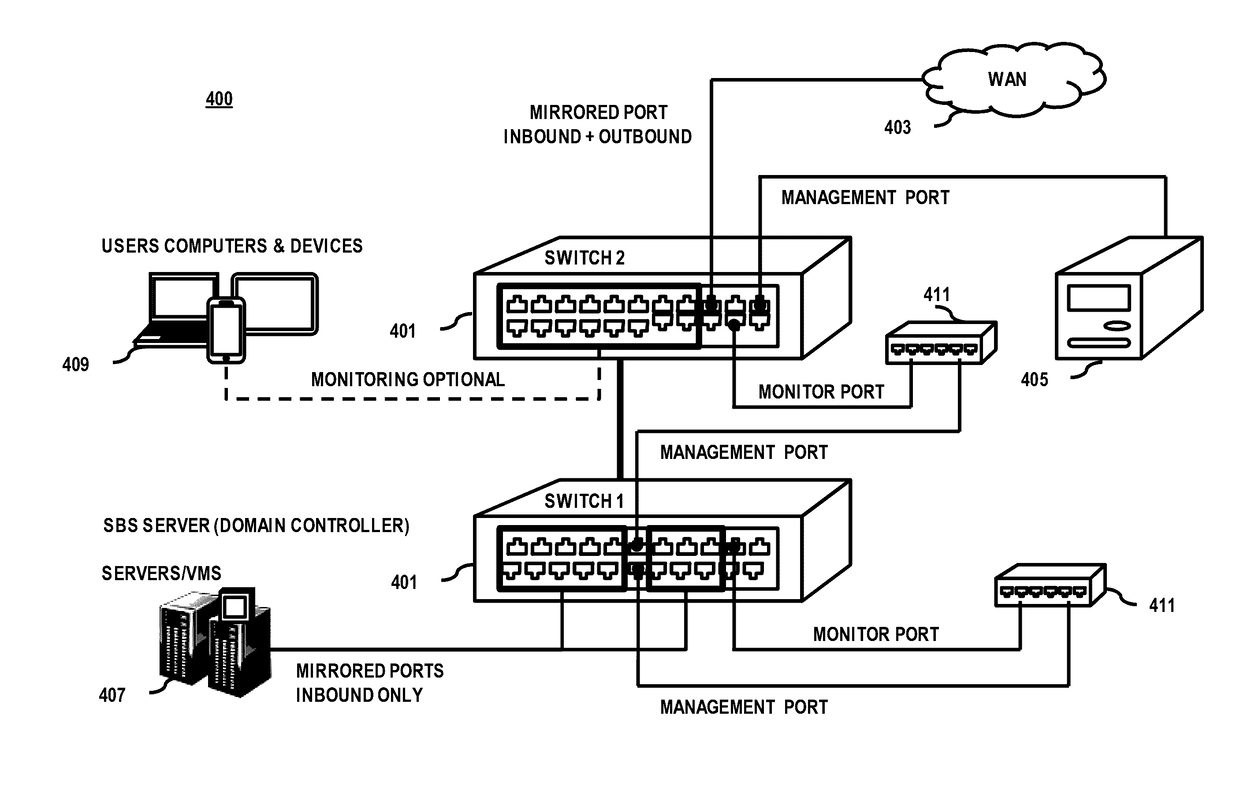

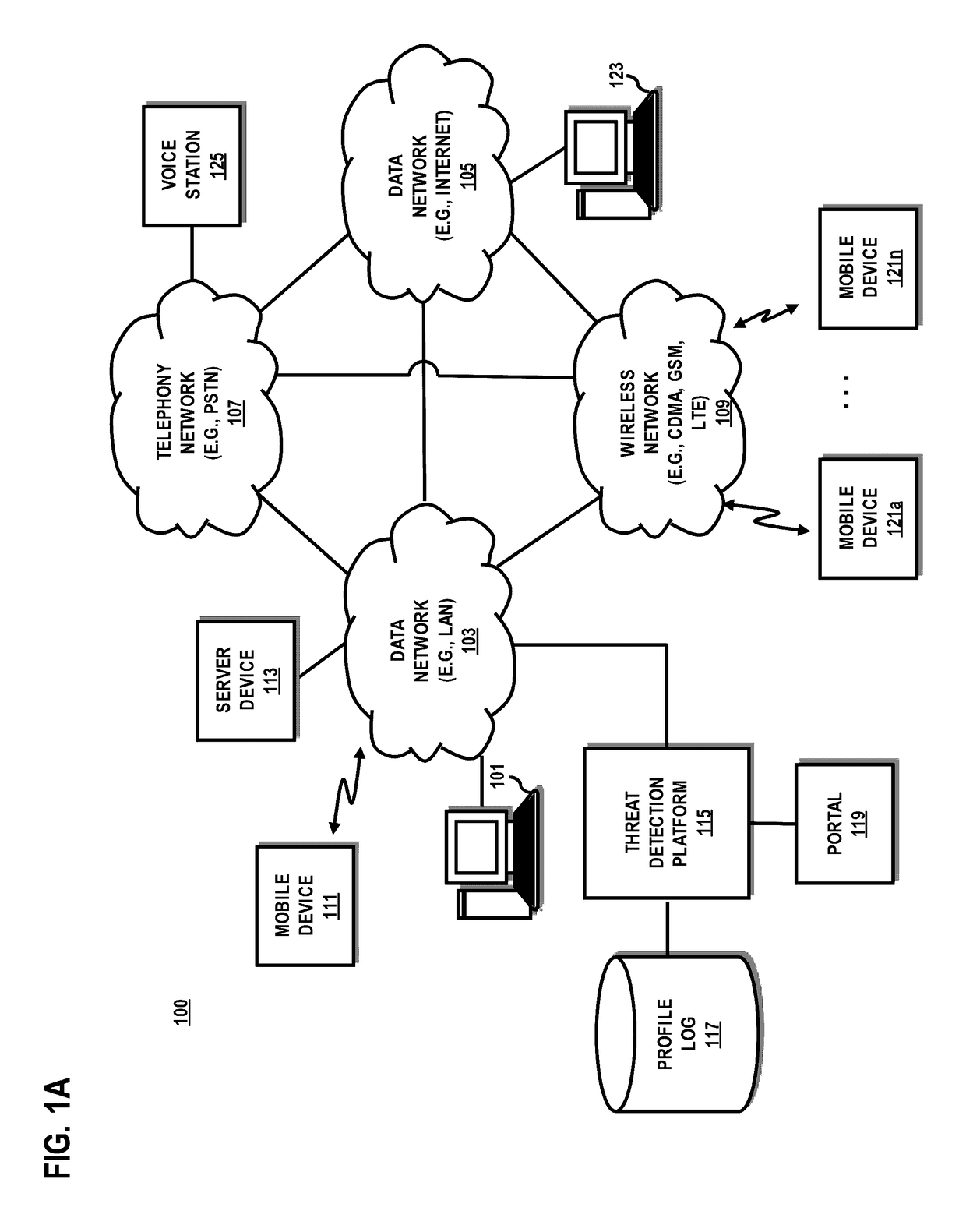

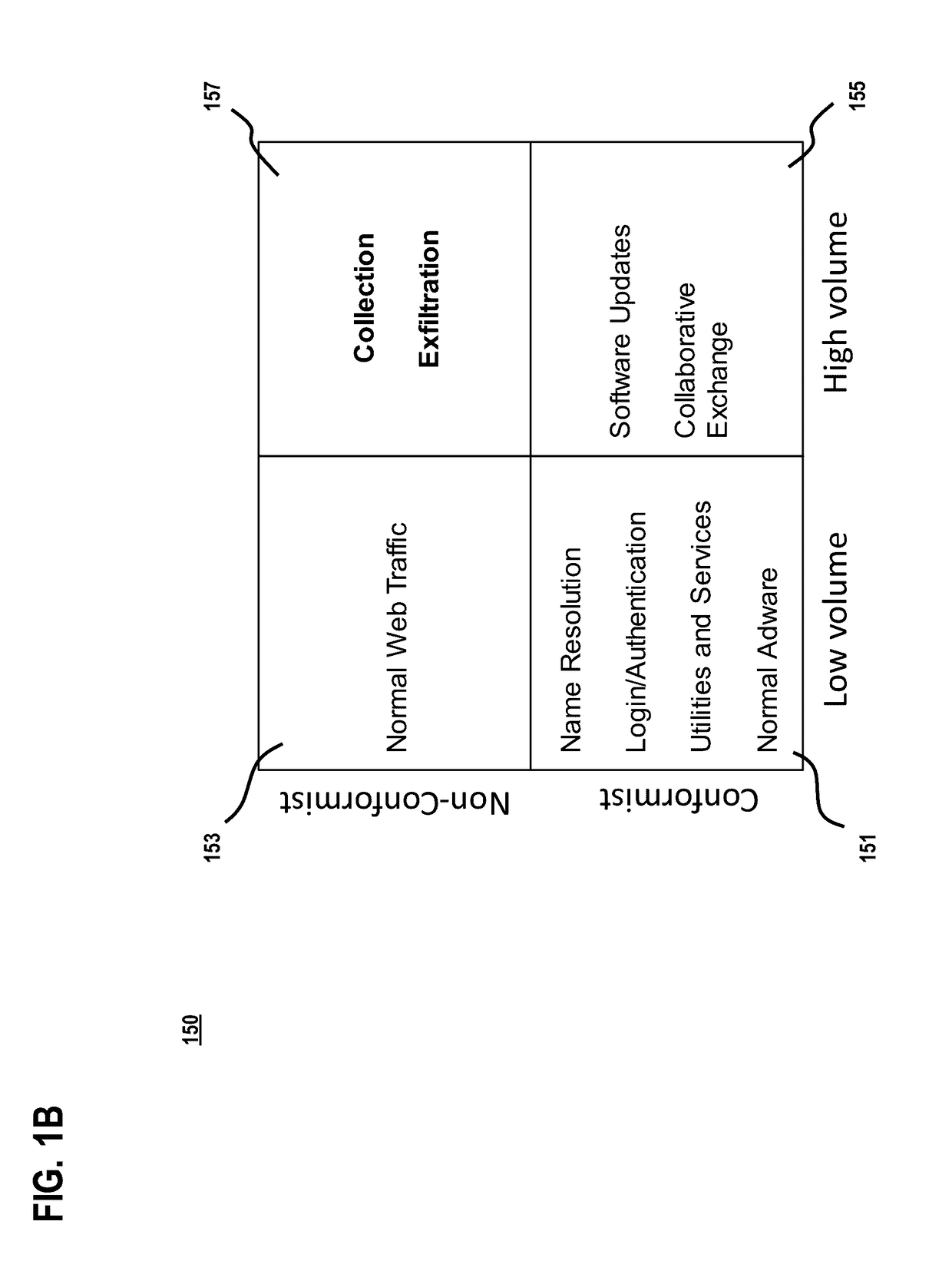

An approach for detecting an insider threat is described. Embodiments include determining one or more features from one or more network transfers among a plurality of network entities, determining a baseline behavioral profile of the plurality of network entities based on the one or more features; and determining at least one malicious network entity from among the plurality of network entities based on a systematic deviation from the baseline behavioral profile of at least one of the one or more features.

Owner:PERSONAM

System and method for detecting insider threats

An approach for detecting an insider threat is described. Embodiments include determining one or more features from one or more network transfers among a plurality of network entities, determining a baseline behavioral profile of the plurality of network entities based on the one or more features; and determining at least one malicious network entity from among the plurality of network entities based on a systematic deviation from the baseline behavioral profile of at least one of the one or more features.

Owner:PERSONAM

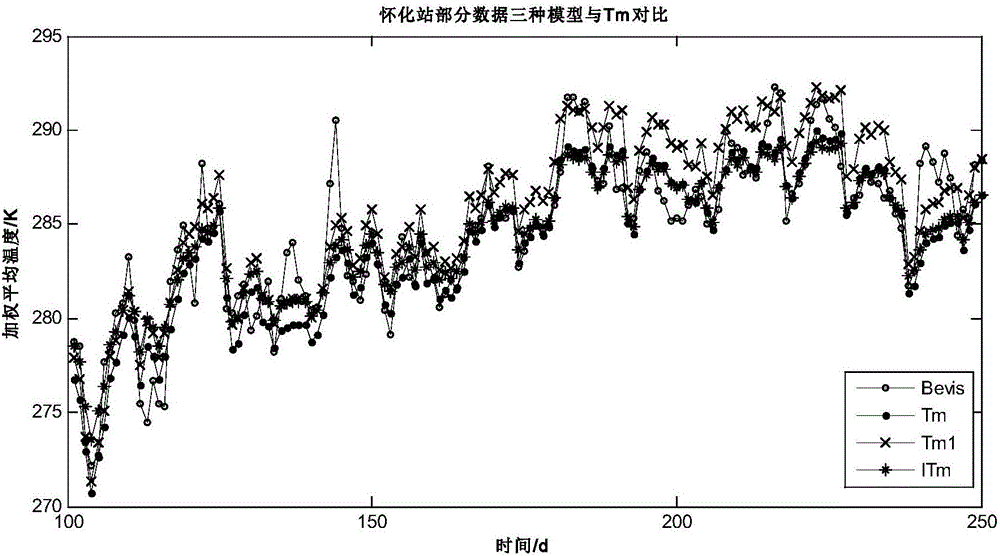

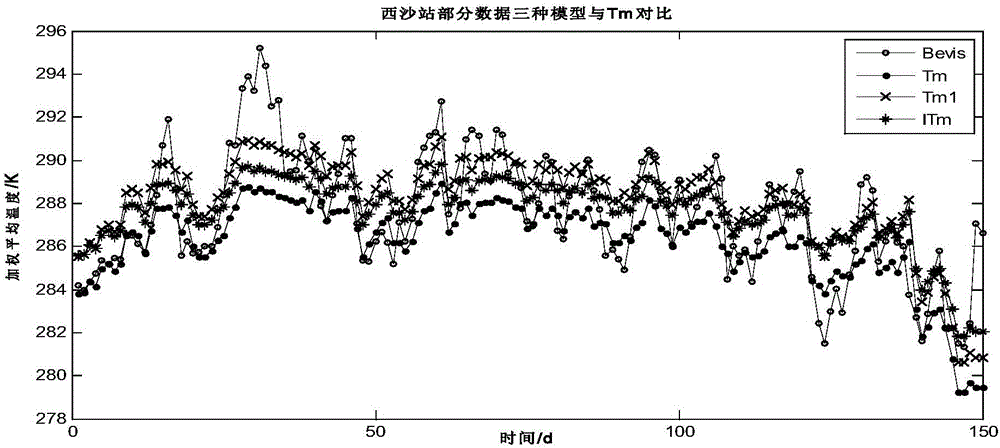

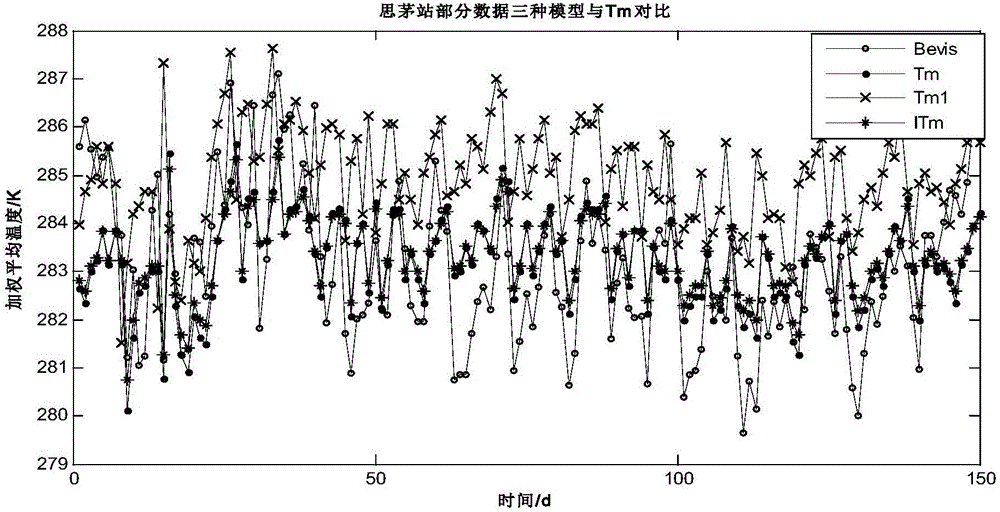

Weighted average temperature calculation method applicable to low latitude regions in China

ActiveCN107180128AIn line with the law of changeEliminate systematic biasDesign optimisation/simulationSpecial data processing applicationsGround temperatureLow latitude

Owner:SOUTHEAST UNIV

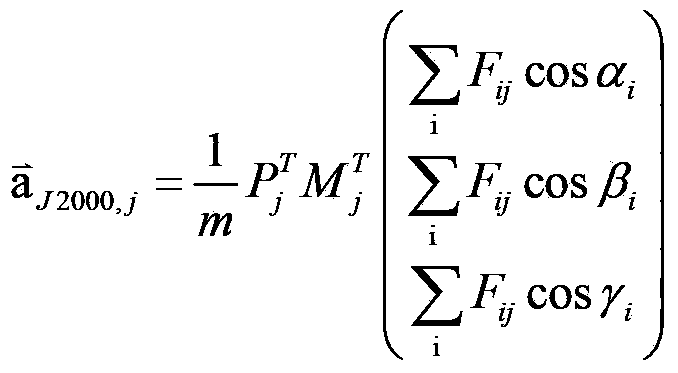

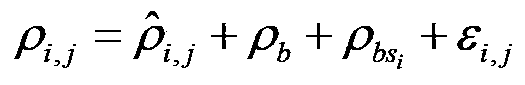

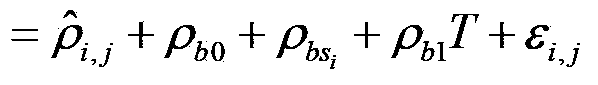

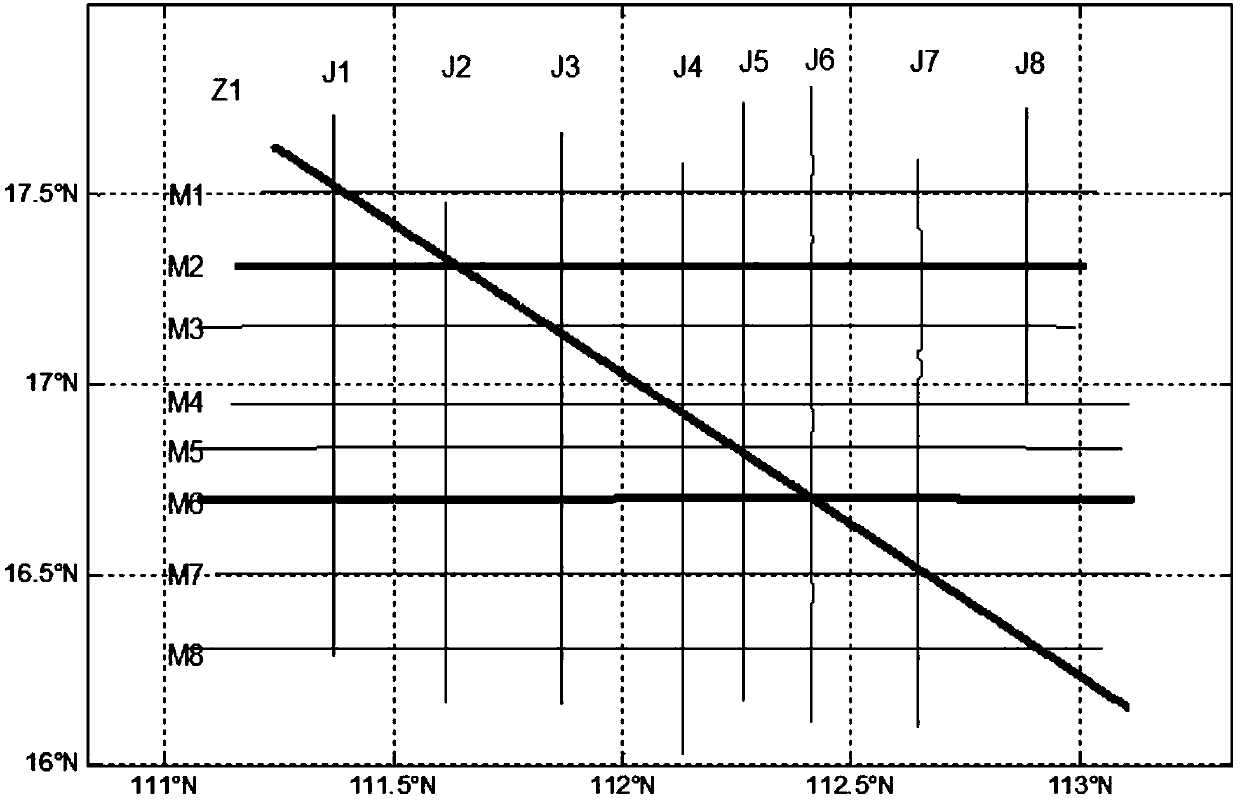

Orbit determination method for geostationary satellite adapting to orbital maneuver

ActiveCN103424116ASolve the difficulties caused by determiningAvoid difficultiesInstruments for comonautical navigationGeosynchronous satelliteSystematic deviation

The invention discloses a precision orbit determination method for a geostationary satellite adapting to orbital maneuver and belongs to the field of space metering and controlling. The method comprises the followings: firstly, maneuvering acceleration is calculated; observed quantity Rho i and observed residual error sequences delta Rho i and j are calculated; estimation to public system error Rho b is performed; the public system error Rho b is deducted from the observed residual error sequences delta Rho i and j, so as to obtain systematic deviations of all observation stations; the Rho b is deducted from the observed quantity, then orbit improvement is performed again on observation data of which system errors are deducted, and calculating is performed again on the improved initial state until orbit convergence, and precision orbit determination for the geostationary satellite is accomplished. The precision orbit determination method provided by the invention has the benefits as follows: difficulty in precision orbit determination caused by pushing force produced by air blast of an engine on a GEO satellite during orbital maneuver can be overcome, meanwhile, public systematic error appraisement and an all-station deviation adapting iteration eliminating method are adopted for solving the problem that systematic errors such as satellite clock errors and time delay of all observation station equipment are hard to separate is solved, and the orbit determination forecast accuracy of the GEO satellite during the orbital maneuver can be effectively improved.

Owner:CHINA XIAN SATELLITE CONTROL CENT

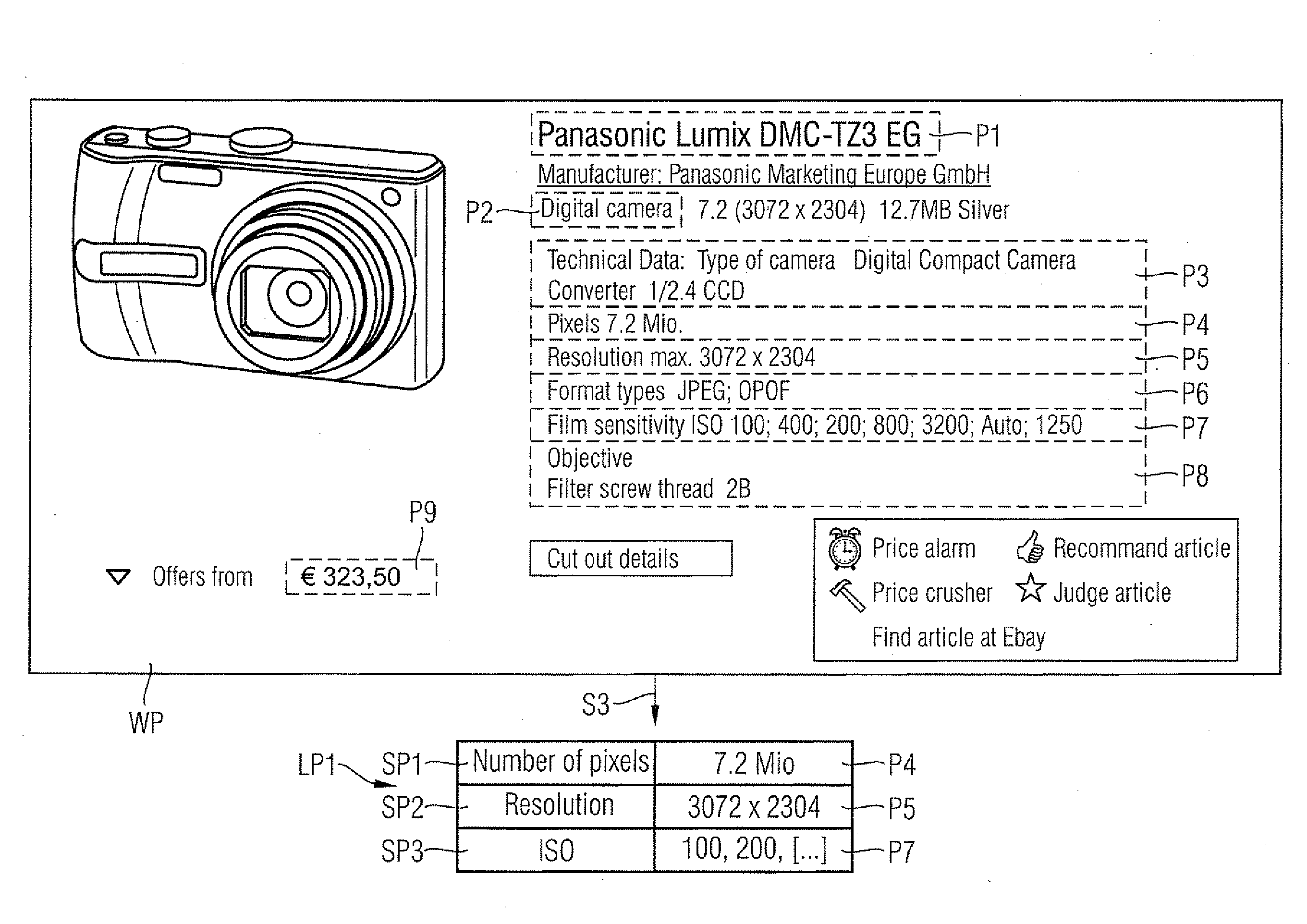

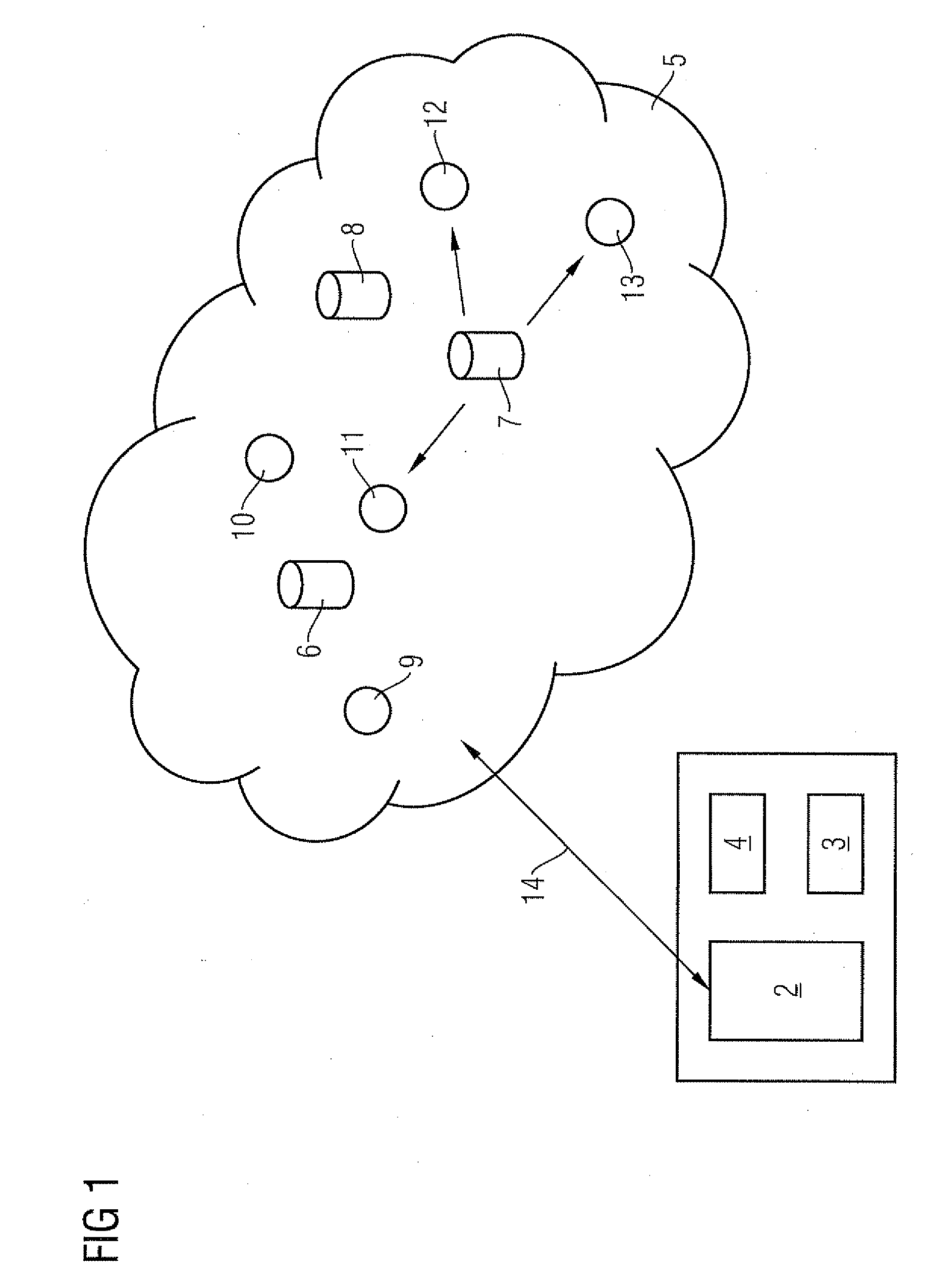

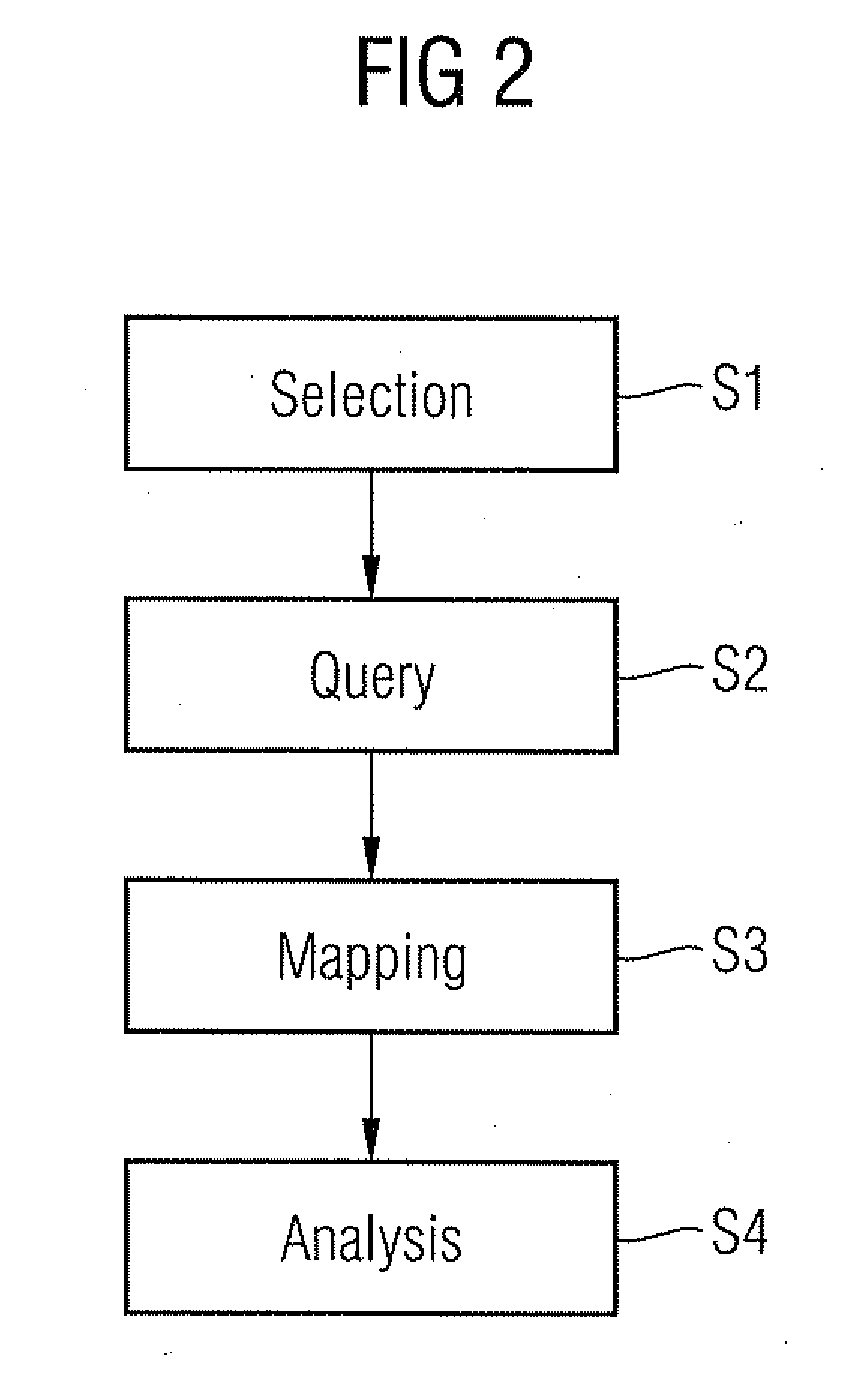

Method and apparatus for comparing entities

A method and apparatus for comparing entities, such as companies or trademarks, based on available pricing and feature information regarding goods or services provided by the companies. Web services, e.g. price finding robots, are employed to obtain pricing and feature information for similar products from different companies. Products having similar features but derive from different companies can be grouped to clusters and be analyzed with respect to average pricing levels. Data formats for pricing and feature information stemming from different web services may be automatically retrieved and mapped into a common format. The method allows to evaluate systematic deviations in the company's pricing policies or to detect if companies do not have a matching product portfolio. One can also estimate the prestige or acceptance of a company or brand as a function of prices tolerated by the underlying market. This may facilitate marketing strategies.

Owner:SIEMENS ENTERPRISE COMM GMBH & CO KG

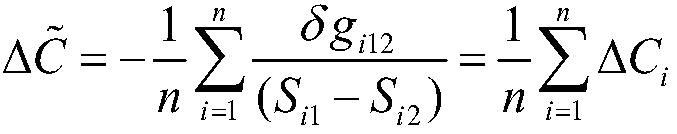

New algorithm for correcting sea and air gravimeter scale value based on repeat line

ActiveCN108387951AMeet needsSimple methodGravitational wave measurementNumerical verificationMathematical model

The invention relates to a new algorithm for correcting the sea and air gravimeter scale value based on the repeat line. The main technical characteristics are that a repeat measuring point scale value correction model is established according to the basic mathematic model of airborne gravity measurement; and the most probable estimation value of the scale value deviation is solved according to the principle of least squares and the sea and air gravimeter scale value is compensated. The formation mechanism of the sea and air gravity measuring system error is analyzed and the sea and air gravimeter scale value calibration error is discovered to be one of the main factors causing the systematic measurement deviation, the calculation model and the compensation method of using the repeat measuring line to detect and correct the sea and air gravimeter scale value are utilized, numerical verification is performed on the reasonableness and effectiveness of the method by using the actual airborne gravity observation network data, the test indicates that the algorithm has a significant effect for eliminating the sea and air gravity measuring systematic deviation, and the method is simple and can meet the requirements of the sea and air gravity measurement user.

Owner:THE CHINESE PEOPLES LIBERATION ARMY 92859 TROOPS

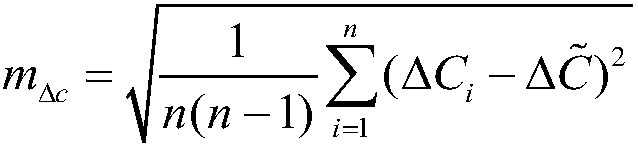

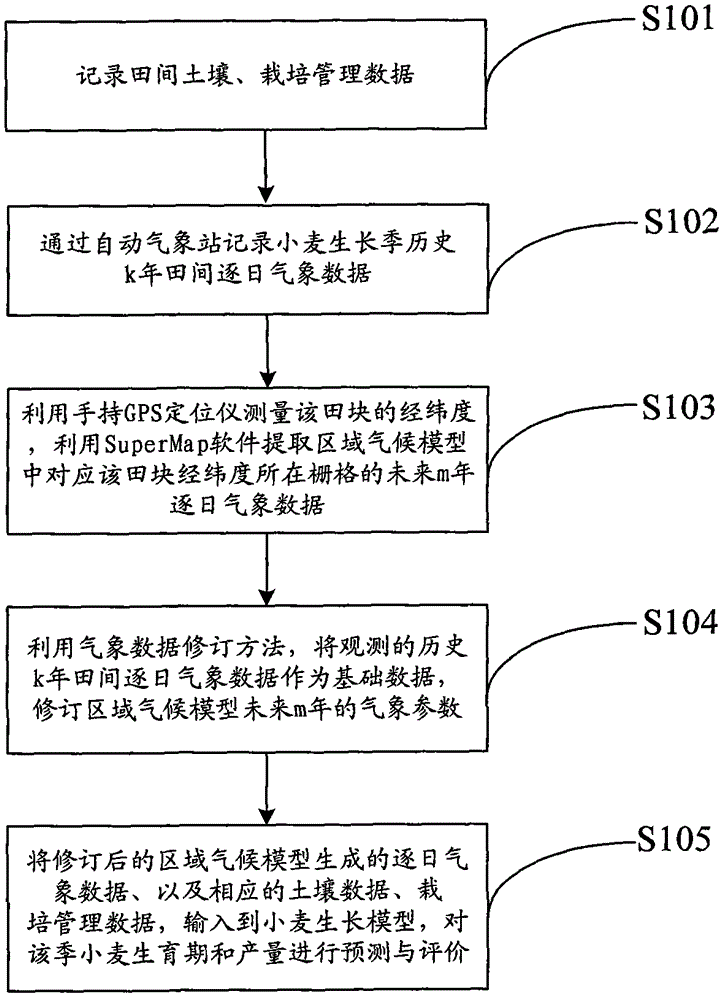

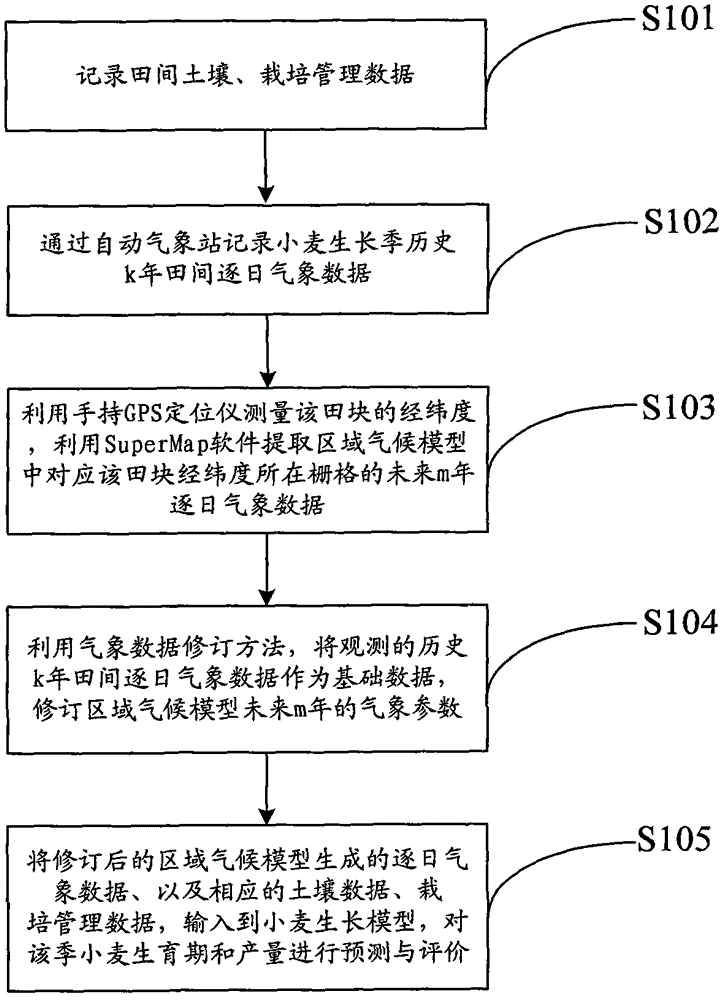

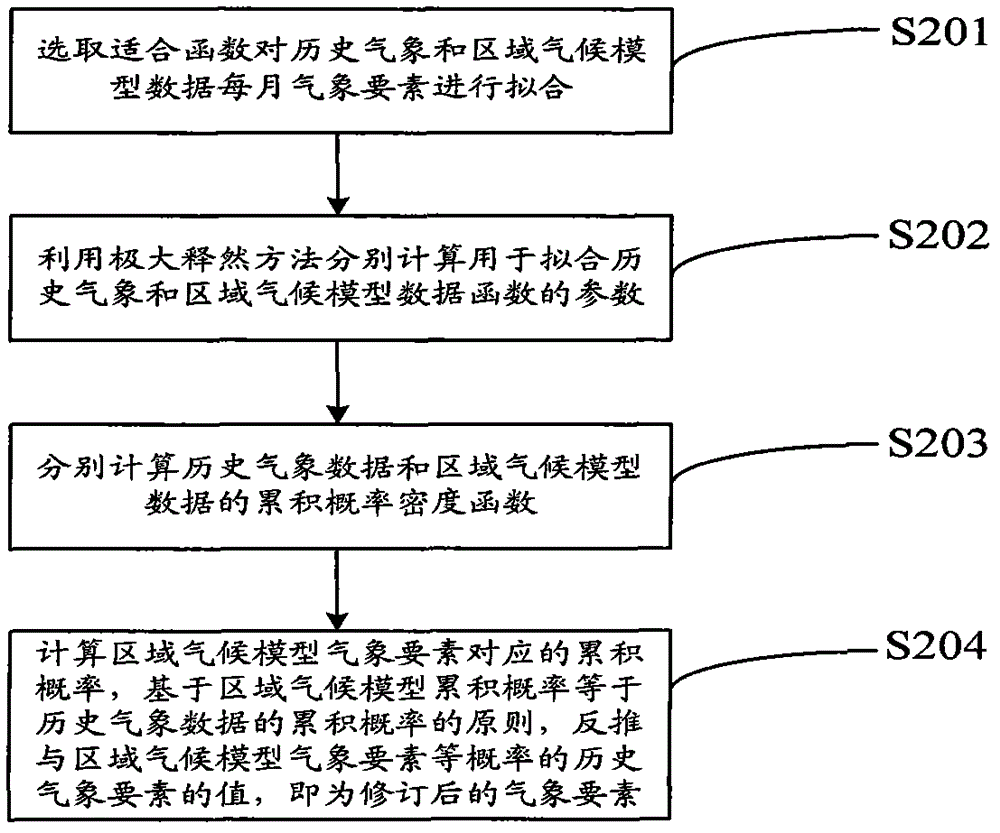

Wheat output predication method based on revised regional climate mode data

ActiveCN102722766AImprove forecast accuracyImprove unityForecastingSystematic deviationComputer science

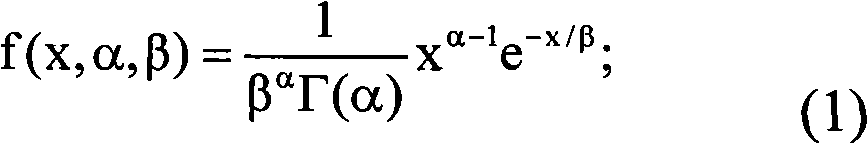

The invention provides a wheat output predication method based on reversed regional climate mode data. By the observed historical daily meteorological data, the data of the daily maximum and minimum temperatures, the rainfall intensity, the rainfall frequency and solar radiation which are revised in a future regional climate mode are revised, so that the data of the regional climate not only keeps the original annular varying pattern, but also complies with the historical meteorological varying pattern of a station, to solve the problems brought about systematic deviation of simulation values and observed data of the regional climate, too few continuous drought days, difficulty in recurrence of high rainfall events, unmatching of time and space scale and the like. The further revised regional climate mode data are combined with a wheat growth simulation system, so that the prediction accuracy of wheat maturity day and wheat output is effectively improved, and the wheat growth simulation system is unified with the regional climate mode on the scale.

Owner:NANJING AGRICULTURAL UNIVERSITY

Reference circuit capable of being calibrated and used for UHF RFID label chip

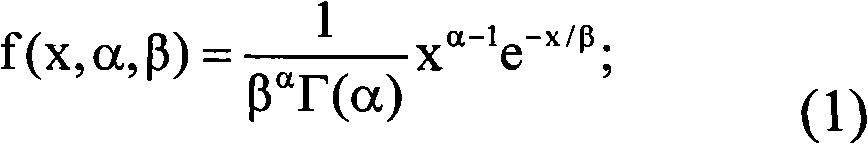

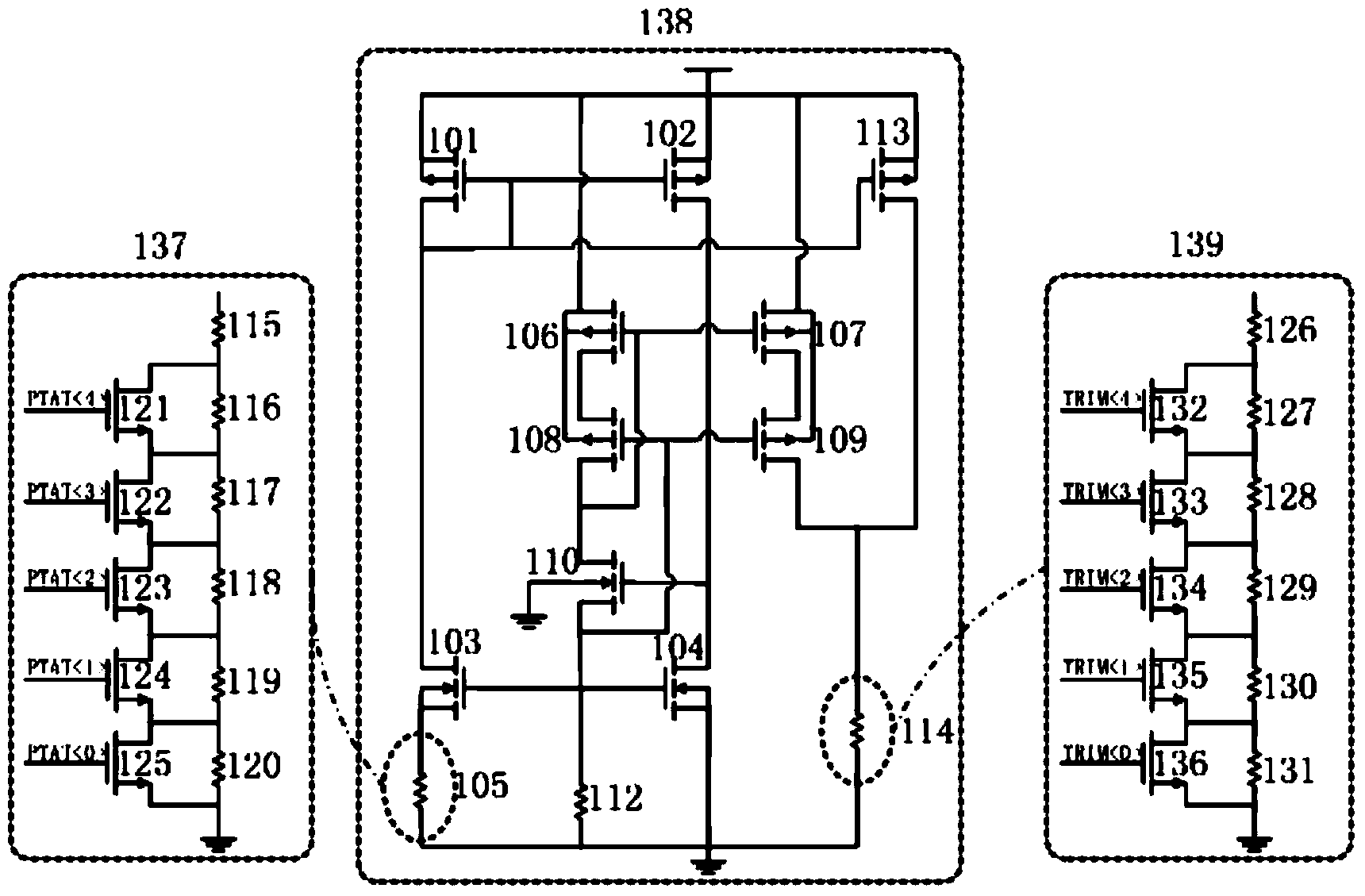

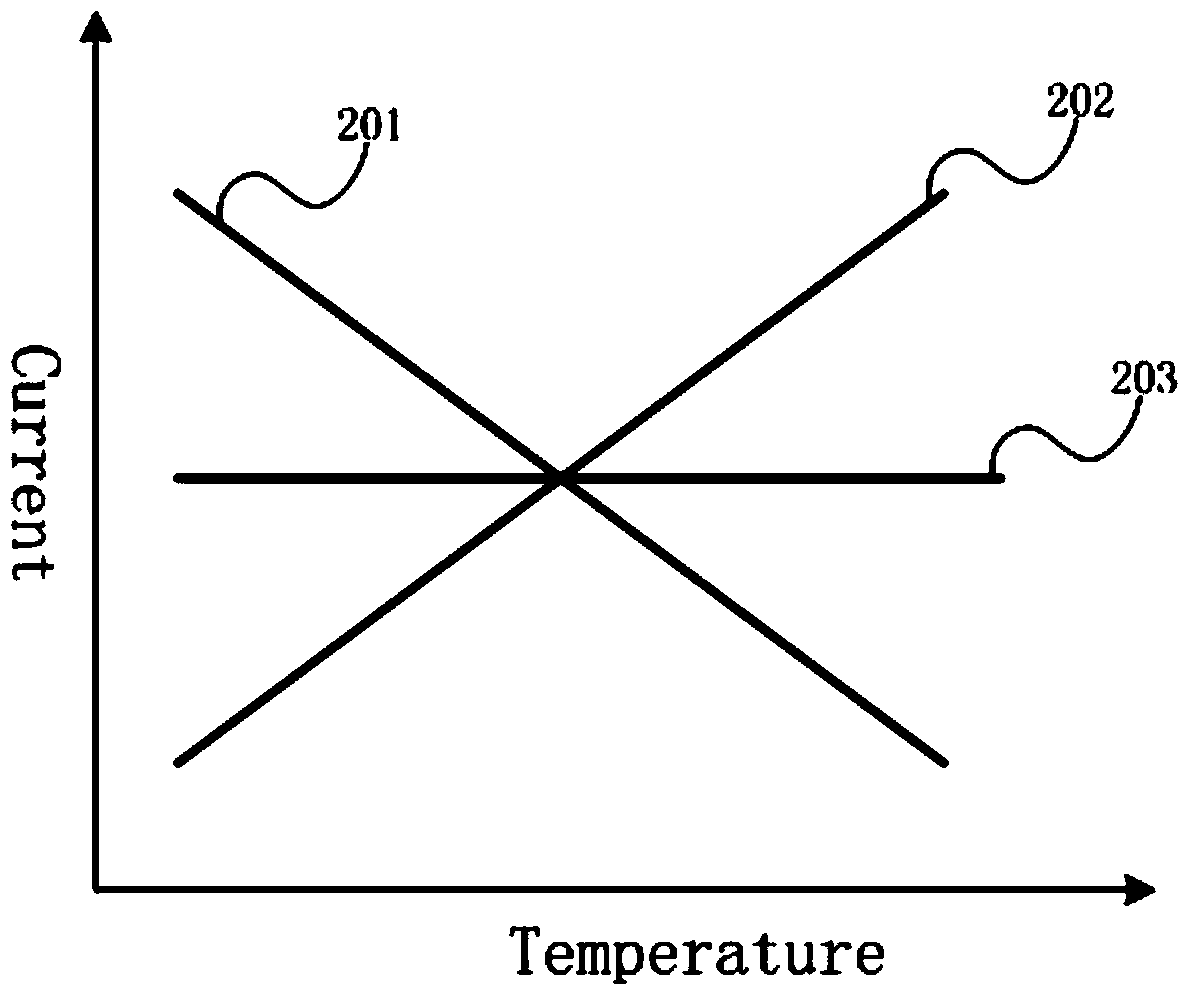

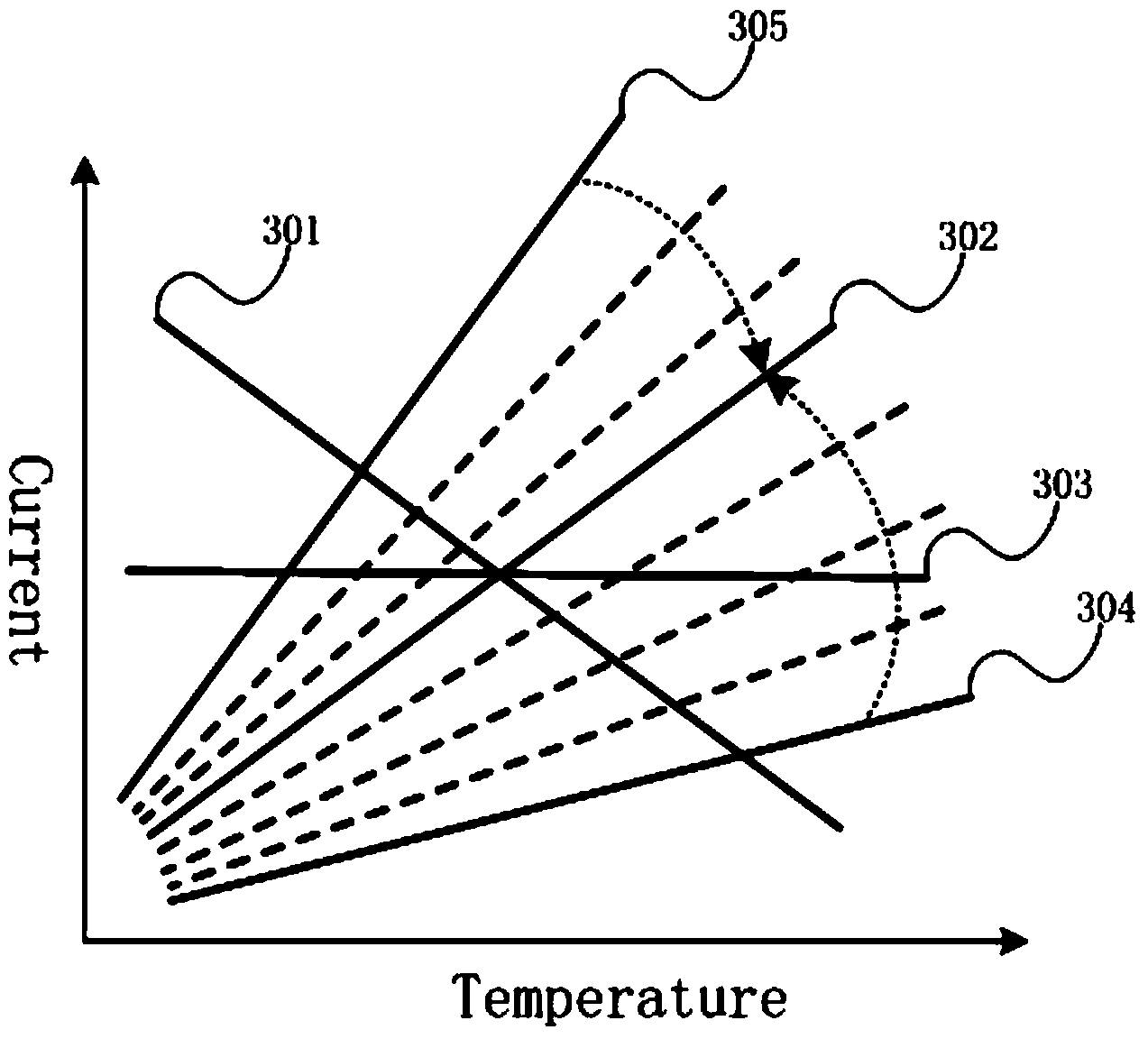

ActiveCN104111686AOvercome human errorImprove efficiencyElectric variable regulationNegative temperatureComputer module

The invention discloses a reference circuit capable of being calibrated and used for a UHF RFID label chip. The reference circuit capable of being calibrated and used for the UHF RFID label chip comprises a standard reference circuit, a PTC (positive temperature coefficient) current calibration circuit and a reference voltage output calibration circuit, wherein the standard reference circuit comprises a PTC electric current generation circuit, an NTC (negative temperature coefficient) current generation circuit and a reference voltage output circuit, and a reference output voltage with the smallest deviation value is obtained by configuring a calibration code. The reference circuit capable of being calibrated and used for the UHF RFID label chip overcomes potential personal error and systematic deviation during the design process, obtains a relatively stable reference voltage value after being calibrated, provides guarantees for subsequently obtaining a stable clock and stable work of a digital module, and improves efficiency of the label chip. The reference circuit capable of being calibrated and used for the UHF RFID label chip achieves a relatively simple mechanism, and completes calibration work under the circumstance of not increasing power consumption.

Owner:NAT UNIV OF DEFENSE TECH +1

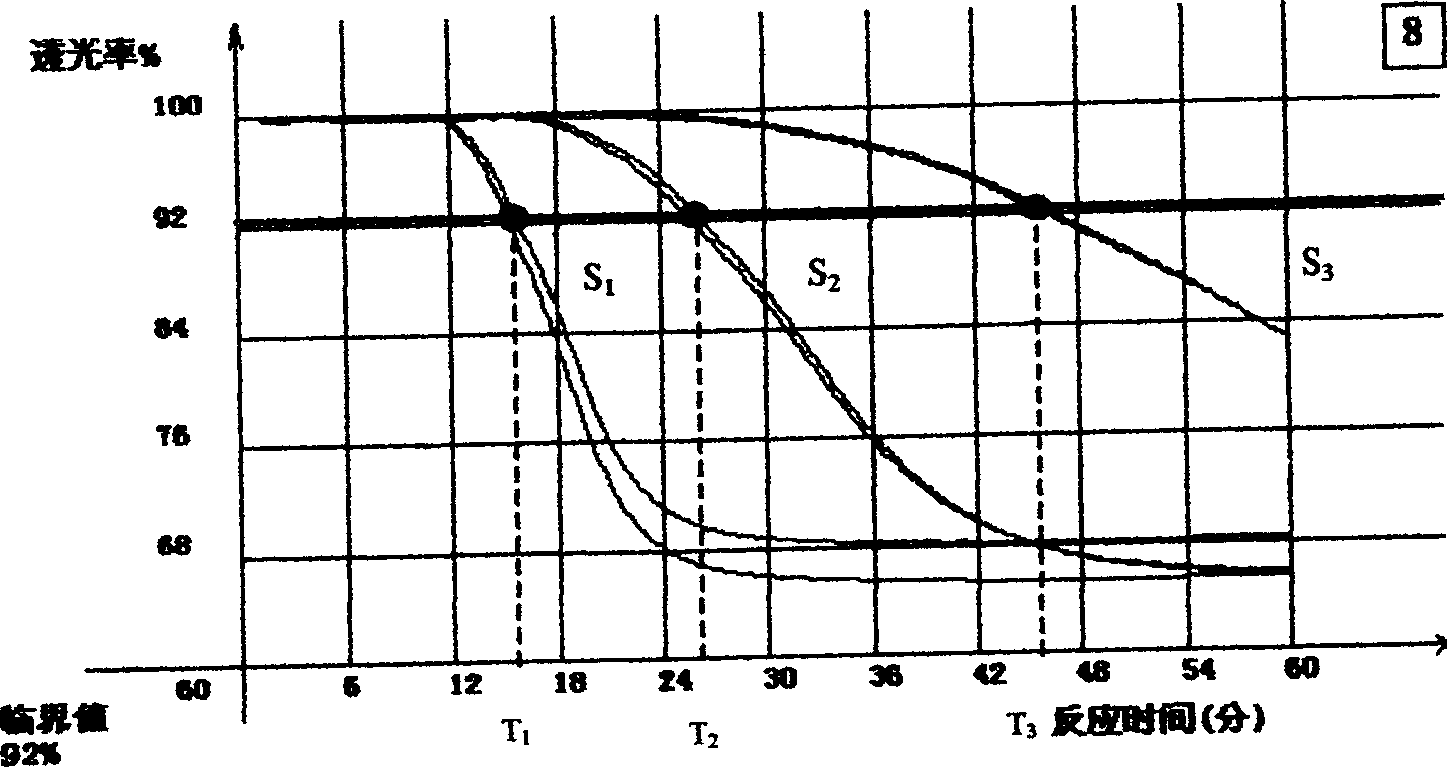

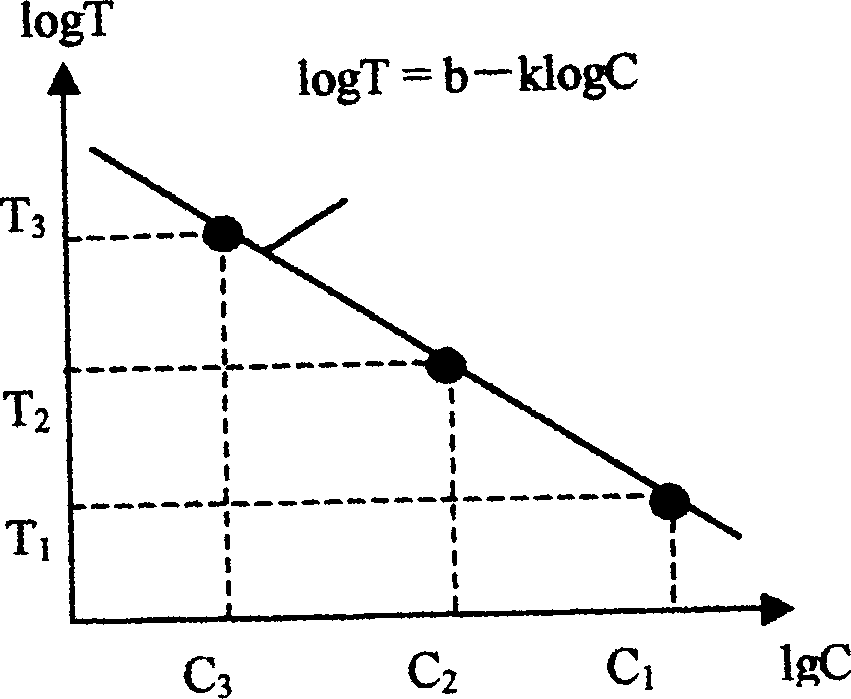

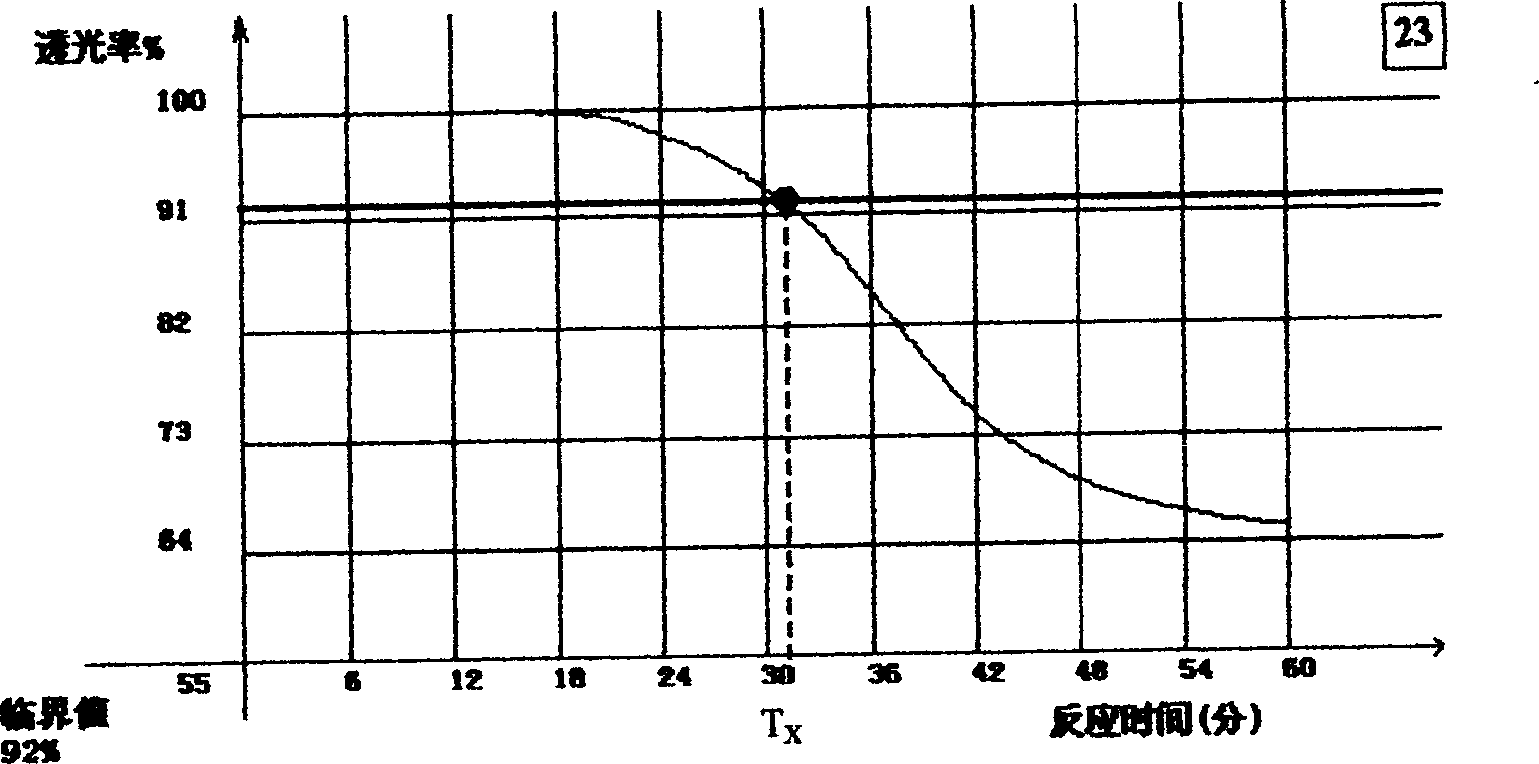

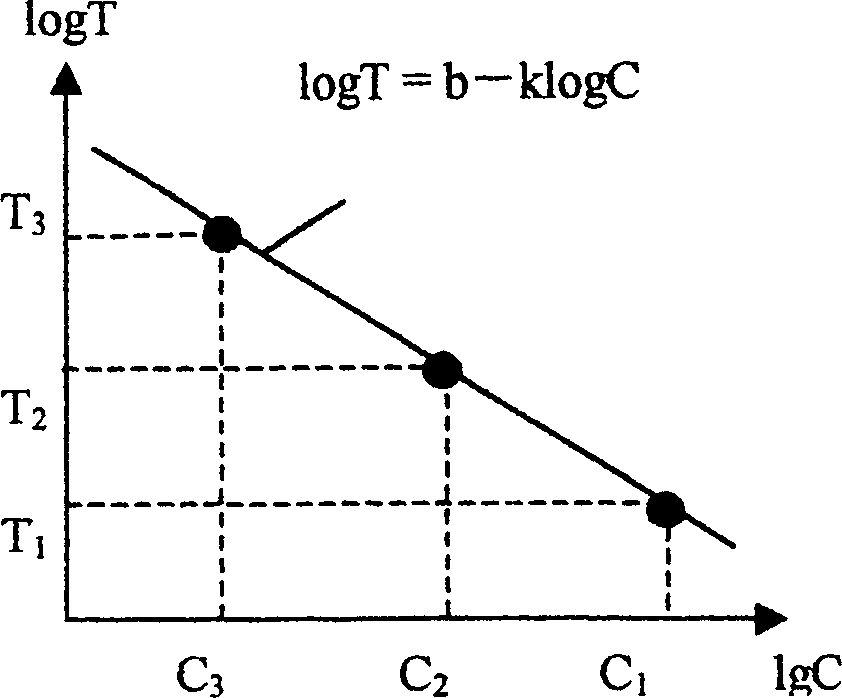

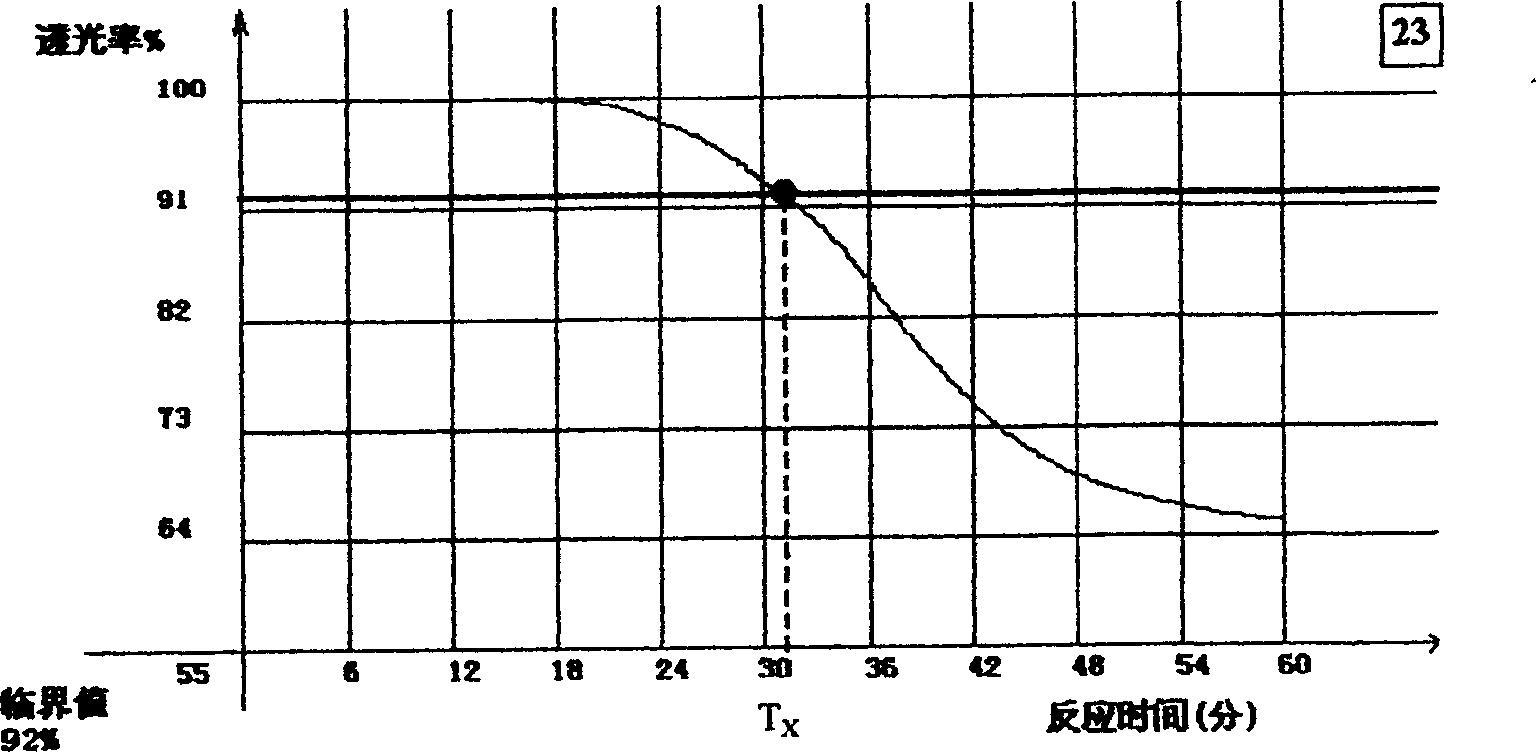

Homologous system model method for quantitatively detecting bacterial endotoxin of blood

InactiveCN1469124AEliminate distractionsEnhanced inhibitory effectColor/spectral properties measurementsBiological testingInterference factorSystematic deviation

The present invention relates to homologous system model method for quantitatively detecting bacterial endotoxin of blood, and aims at solving the problem of difference or interference caused by different system property. In the system model method, one new concept is proposed for solving the BET interference of the sample, i. e., all the unkown interference factors are considered as systematic deviation. Once the systematic deviation is eliminated, the said BET interference of the sample will be eliminated. In some reaction system, digital model is established and sample is detected in the same system, the difference caused by different system property will be eliminated.

Owner:湛江安度斯生物有限公司

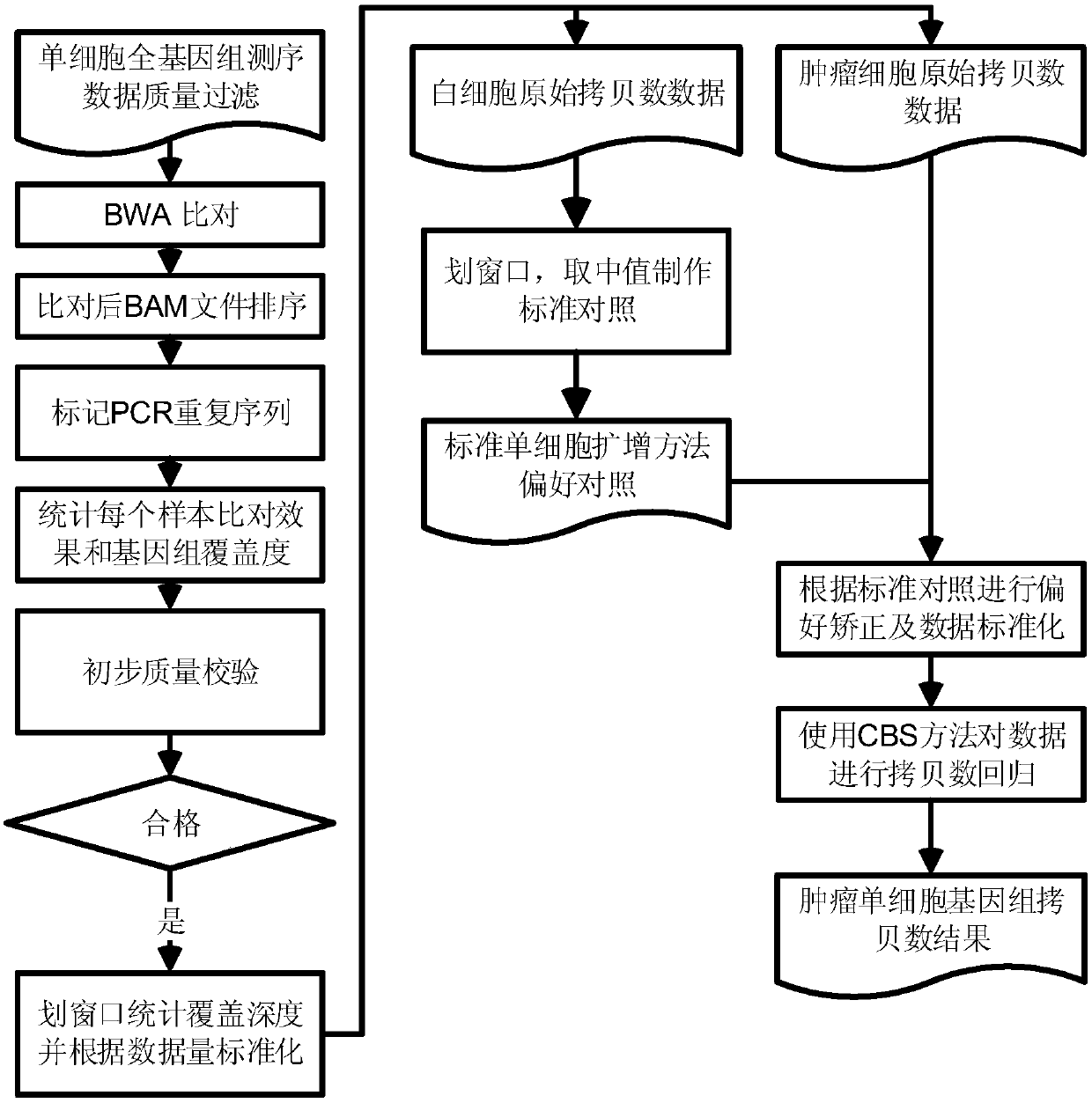

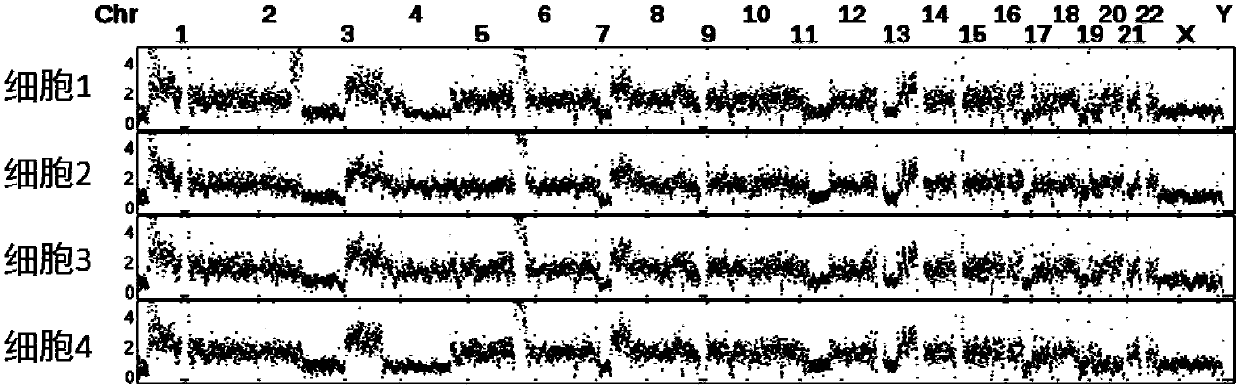

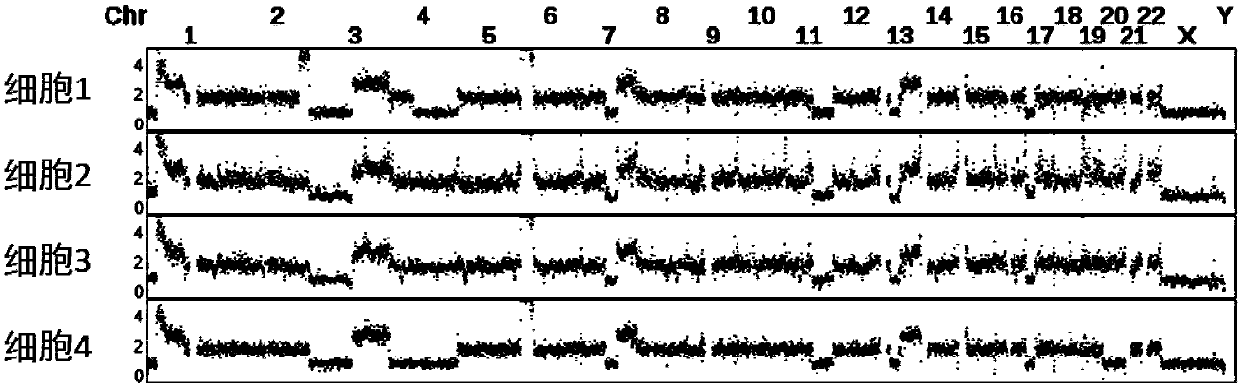

Method for detecting copy number variation of tumor single-cell genomes

ActiveCN110016497AStable returnGood effectMicrobiological testing/measurementProteomicsGenomic sequencingGenome evolution

The invention discloses a method for detecting copy number variation of tumor single-cell genomes. The method comprises the steps of separately performing genome sequencing on tumor single cells and aplurality of normal tissue single cells, performing comparing with a reference genome, and dividing window and standard window data; and using a normal single-cell comparison as a standard for removing systematic deviation to obtain genome copy number in all tumor single-cell regions. The method disclosed by the invention eliminates some specific system deviation introduced by different single-cell amplifying techniques, so that the accuracy of copy number variation detection of the tumor single-cell genomes can be improved, and the method has important significance in detecting driving incidents relevant with copy number variation and reading tumor genome evolution information.

Owner:PEKING UNIV

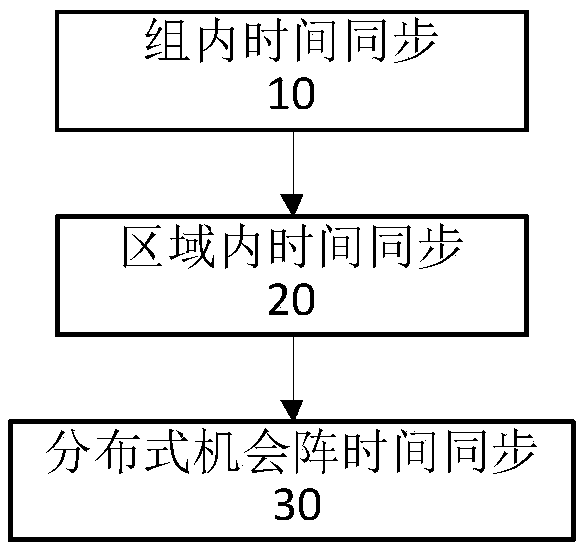

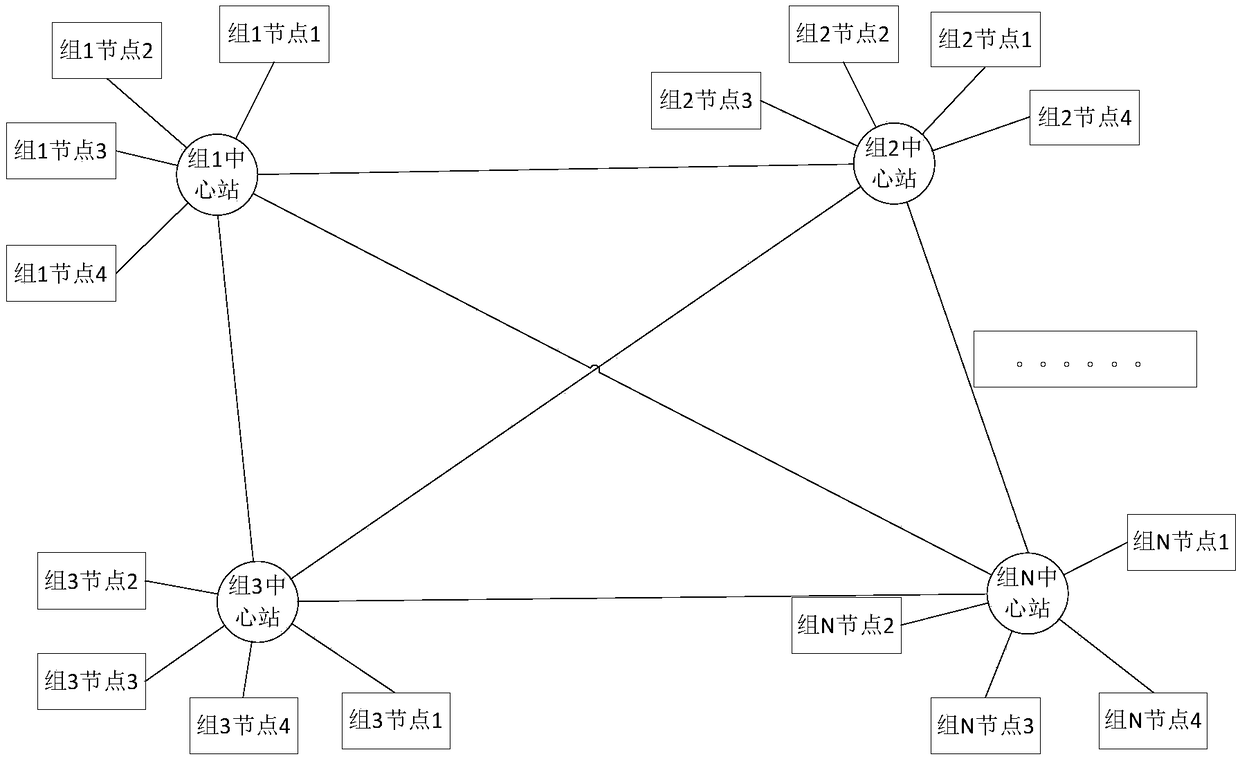

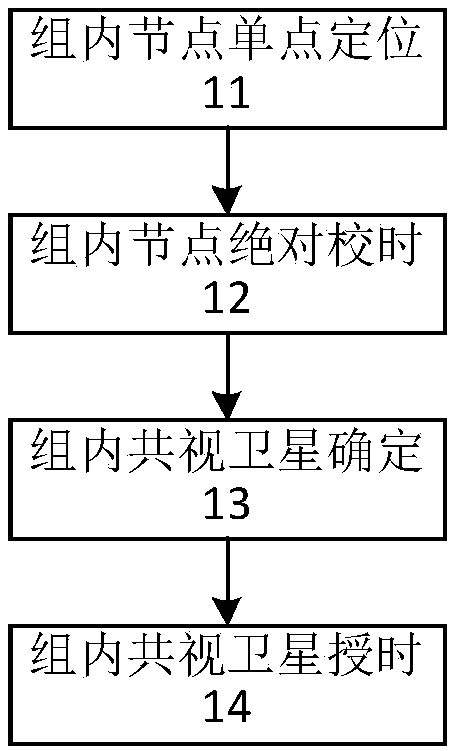

Distributed opportunistic array radar time synchronization method

InactiveCN109407082ASynchronized High Precision TimeEliminate "systematic bias"Satellite radio beaconingRadio wave reradiation/reflectionRadarSystematic deviation

The invention discloses a distributed opportunistic array radar time synchronization method. According to the method, in a group, intra-group time synchronization is performed with co-view satellitesin the group adopted as references, so that systematic deviation between intra-group nodes can be eliminated; in a region, one intra-group co-view satellite is adopted as a common regional co-view satellite, so that the systemic deviation between inter-group nodes can be eliminated; and the high-precision time synchronization of each node in the entire region is achieved. In a distributed opportunistic array radar, each opportunistic subarray can be used as a node, and the high-precision time synchronization of the entire distributed opportunistic array radar is realized with the time synchronization method of the present invention.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

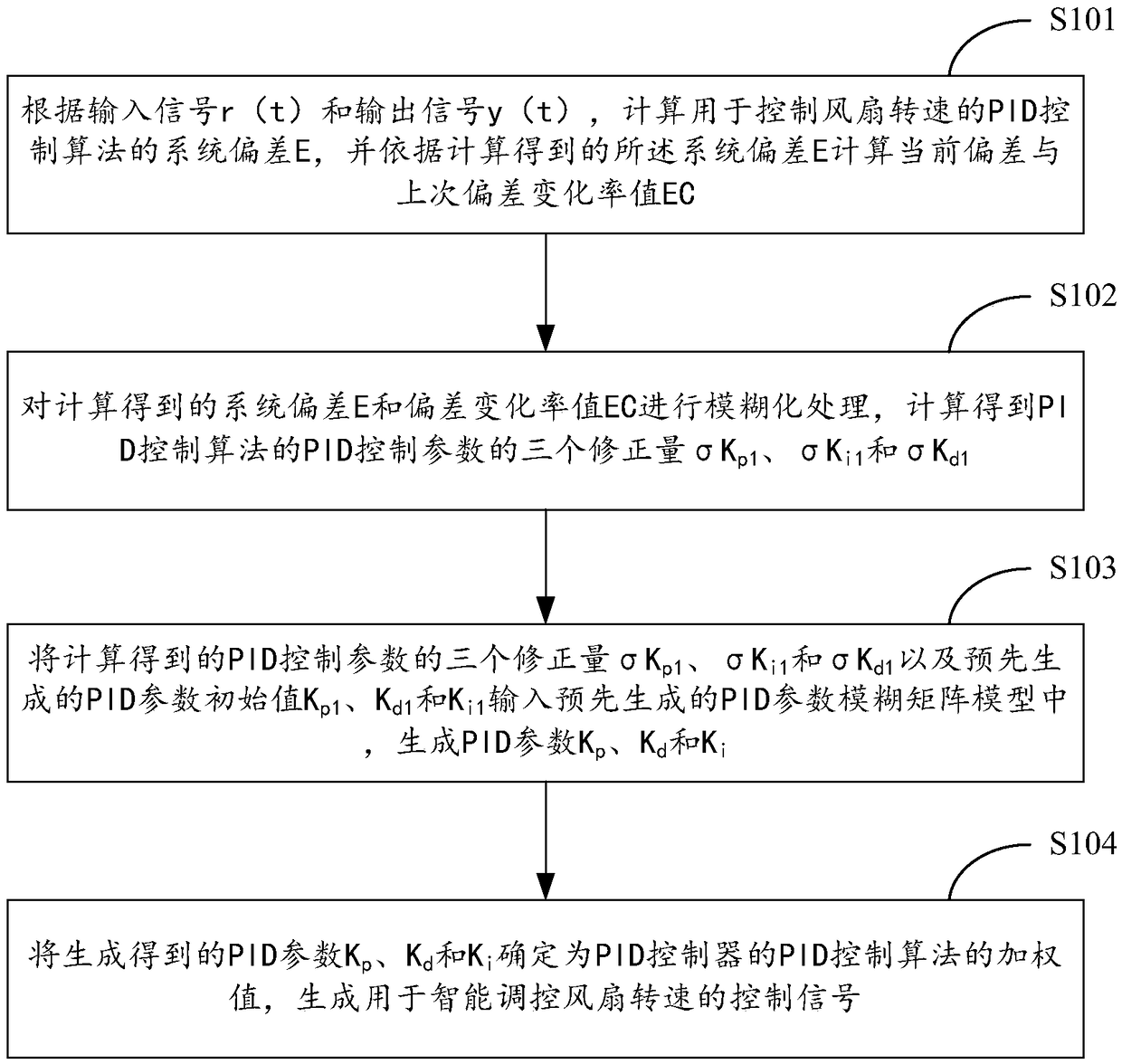

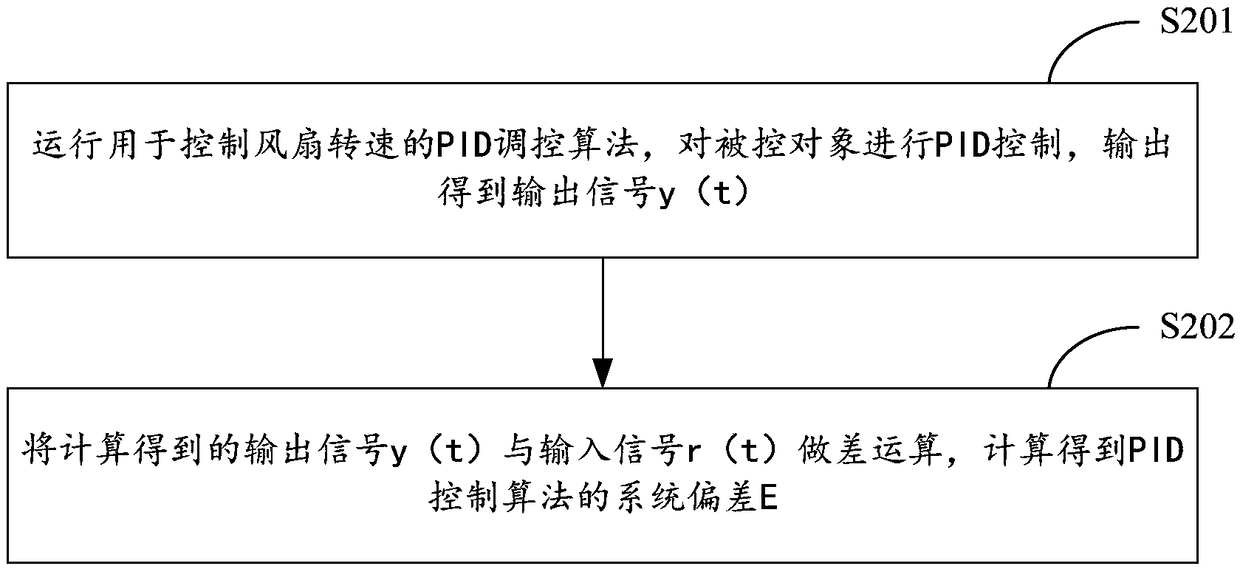

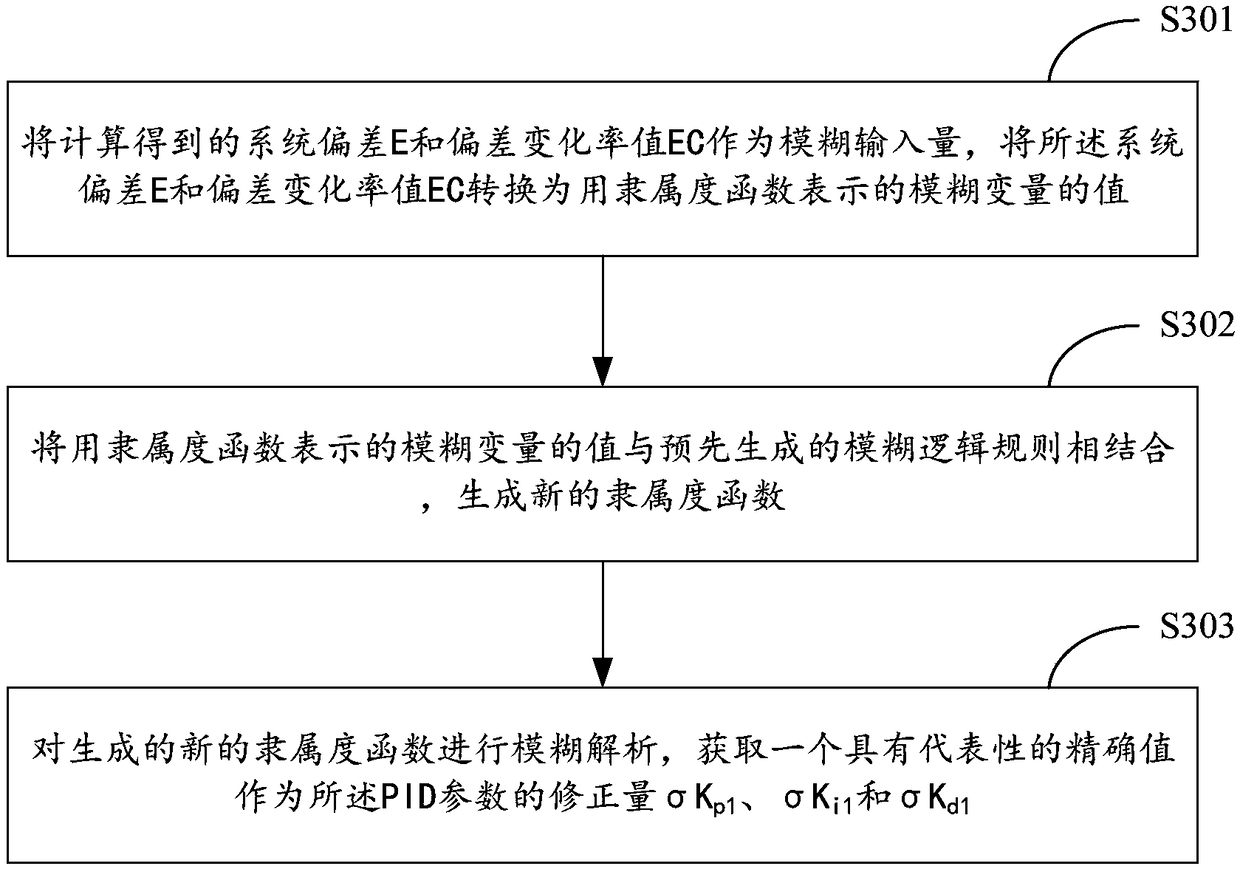

Intelligent fan regulating method and system applied to universal fan types

InactiveCN109236713AGuaranteed to workAvoid manual adjustmentPump controlNon-positive displacement fluid enginesPid control algorithmControl signal

The invention relates to the technical field of heat dissipation of servers, and provides an intelligent fan regulating method and system applied to universal fan types. The method comprises the stepsthat systematic deviation E and a deviation variation rate value EC are calculated; the systematic deviation E and the deviation variation rate value EC are subjected to fuzzing processing, and threecorrections of sigma Kp1, sigma Ki1 and sigma Kd1 of PID control parameters of a PID control algorithm are calculated and obtained; PID parameters of Kp, Kd and Ki are generated; the PID parameters of Kp, Kd and Ki are designed as weighted values of a PID control algorithm of a PID controller, and a control signal used for intelligently regulating the rotational speed of a fan is generated, therefore PID intelligent regulating of a server fan is achieved, manual adjusting wasting time and labor is avoided, and it is ensured that all elements and devices of the server work within a safe temperature value range.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

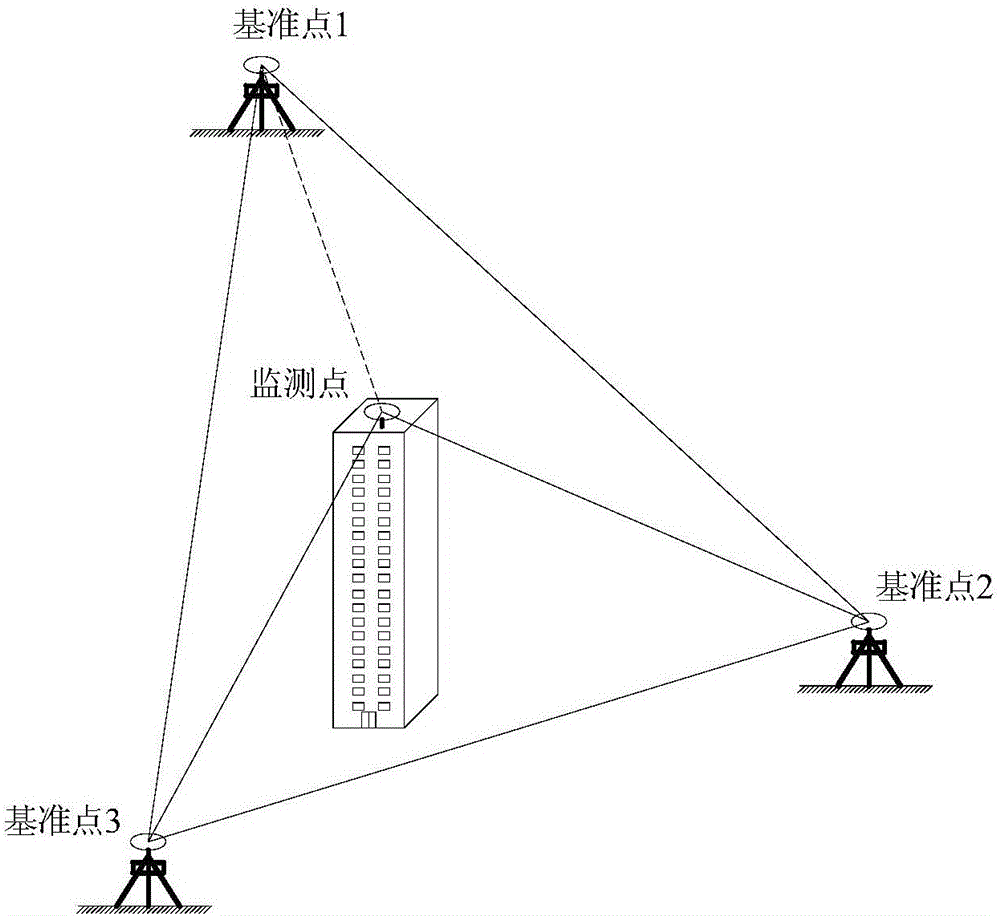

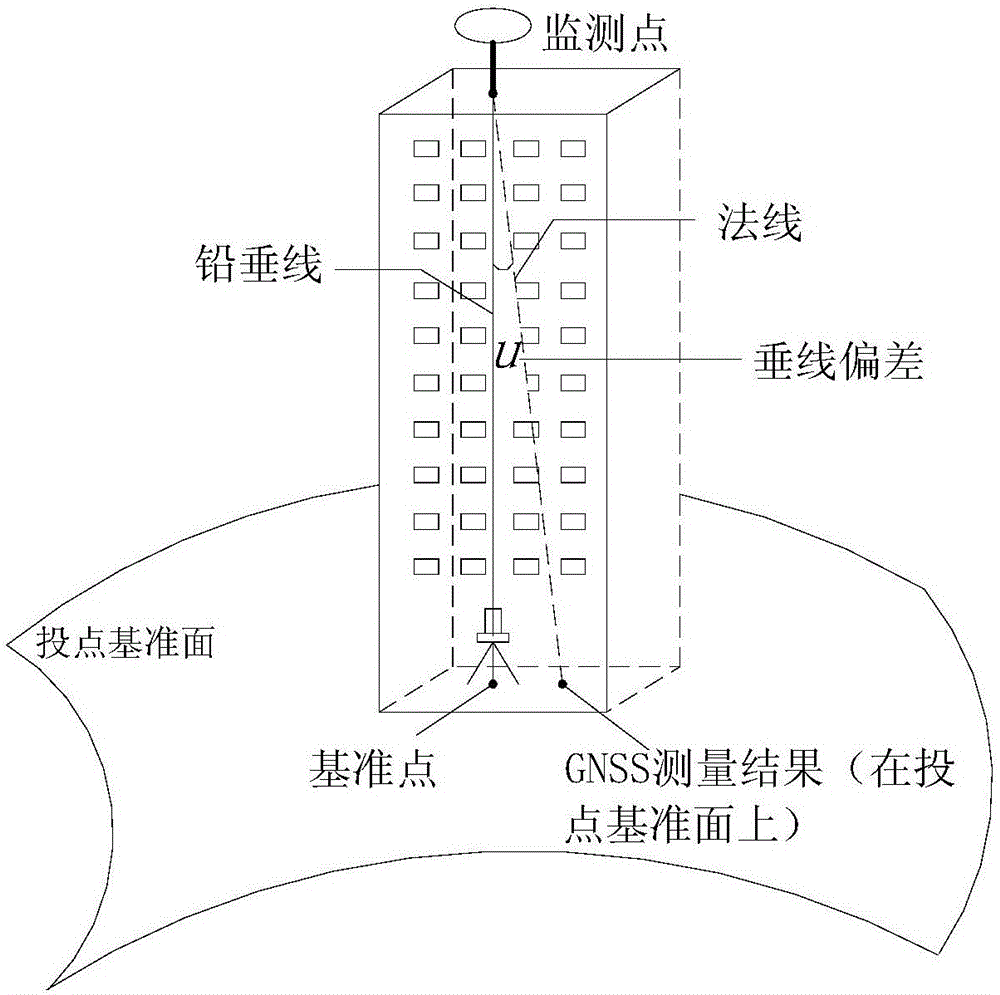

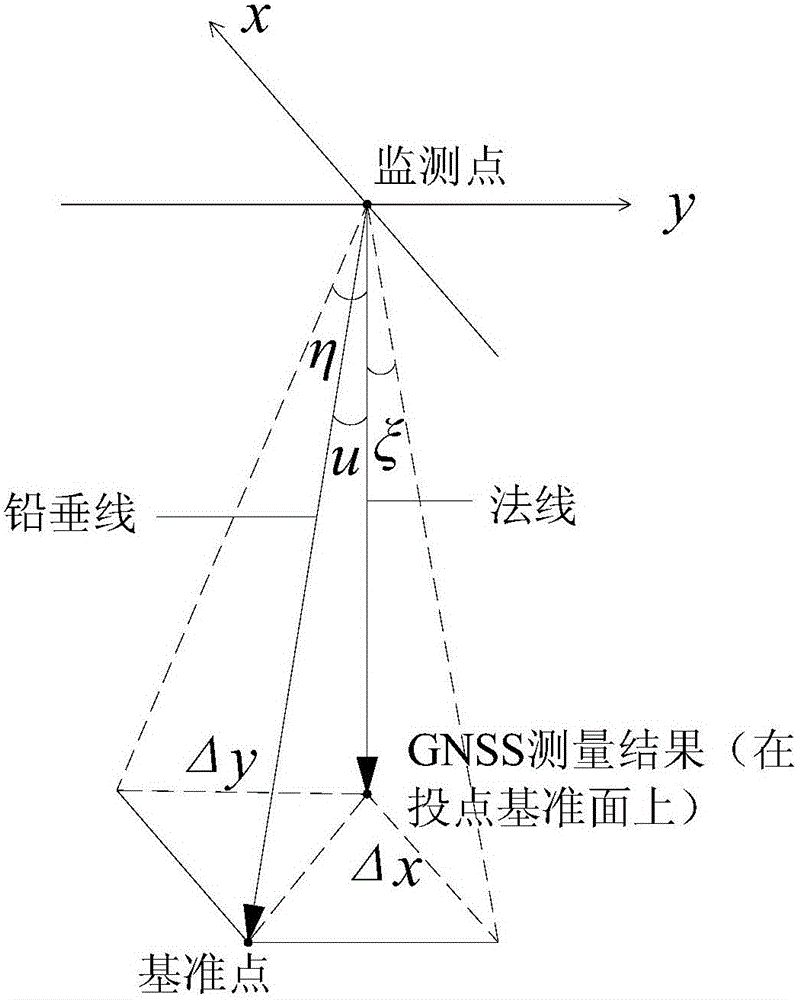

Independent monitoring method for construction verticality of super-high building

InactiveCN106017444ARealize verticality monitoringGood rapportUsing optical meansFixed angles setting outVertical deflectionPrime vertical

The invention discloses an independent monitoring method for the construction verticality of a super-high building. The independent monitoring method comprises the following steps: (1) conducting networking synchronous long-term observation on datum points and a monitoring point, and acquiring the construction coordinates of the monitoring point according to a classical static baseline calculation and network adjustment; (2) calculating the meridional component Xi and the prime vertical component ita of the plumb line deviation of the monitoring point by fusing a plurality of earth's gravity field models or via a regional quasi-geoid model; (3) calculating the systematic deviation between GNSS measurement and a laser plummet apparatus projection point according to the calculated the plumb line deviation, so as to solve the matching problem of GNSS measurement and the laser plummet apparatus projection point; (4) comparing a result of GNSS measurement with a result of the laser plummet apparatus projection point to evaluate the construction verticality of the super-high building. The independent monitoring method has the characteristics of being good in coherence with the datum points, capable of realizing automatic continuous observation, high in precision and independence, and the like, and has very high application value.

Owner:GUANGDONG UNIV OF TECH

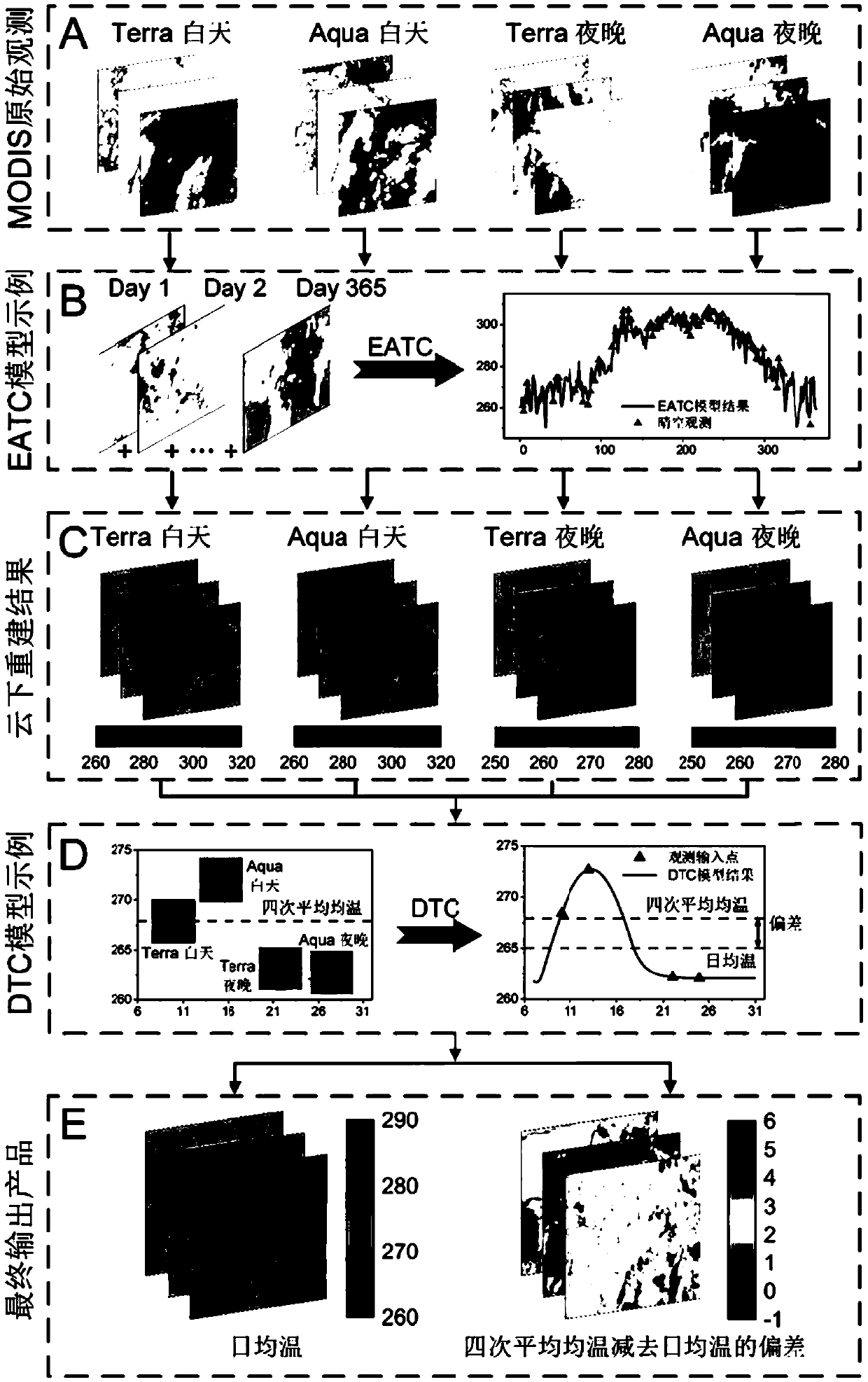

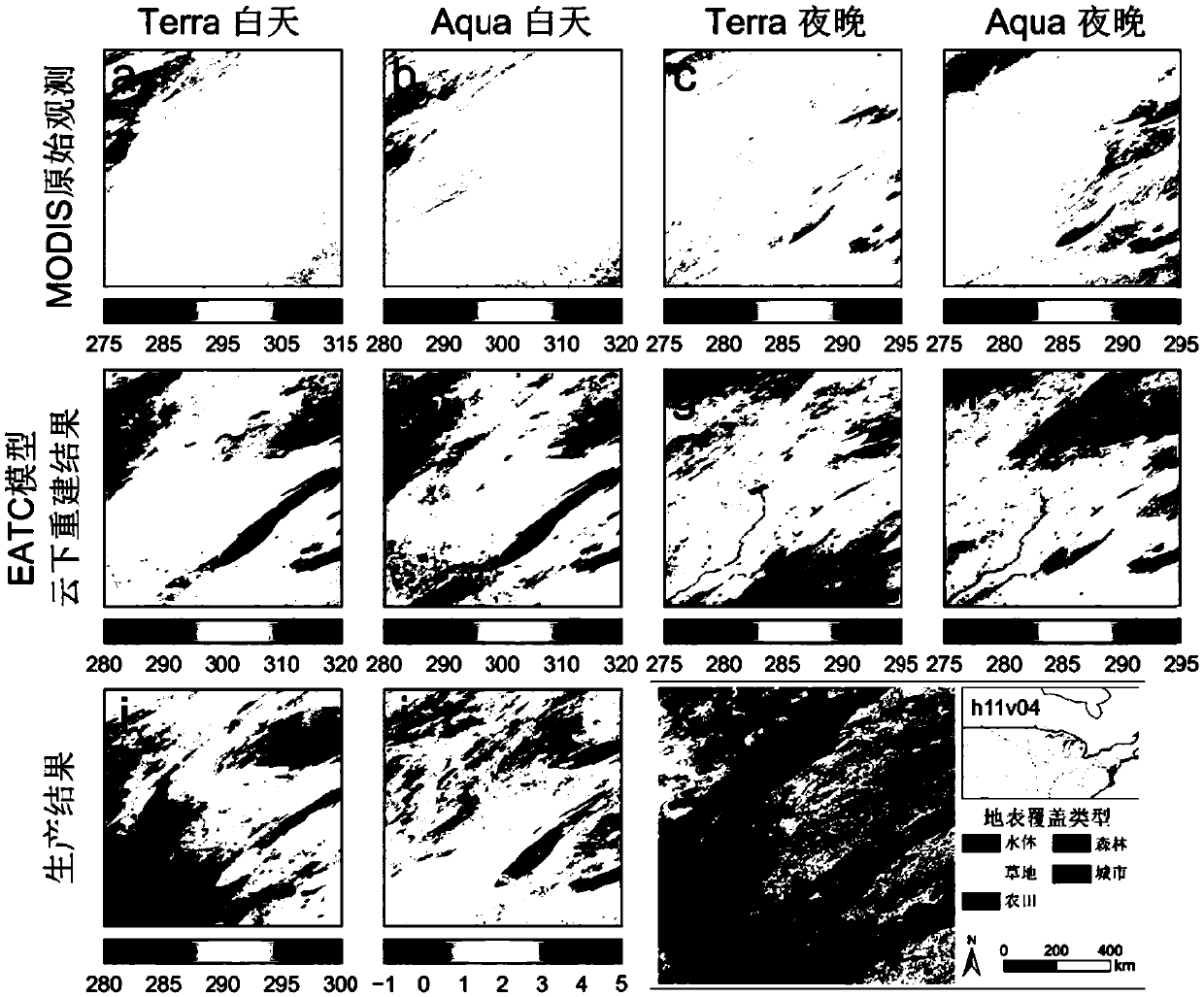

Remote sensing surface daily average temperature calculation method based on multi-time scale model

InactiveCN109635242ACorrect Systematic BiasImprove applicabilityComplex mathematical operationsScale modelAtmospheric sciences

The invention relates to a remote sensing surface daily average temperature calculation method based on a multi-time scale model, and the method comprises the steps: respectively reconstructing the under-cloud surface temperature of a satellite at each transit moment through an ATC model, and ensuring the time and space continuity of a surface temperature observation result; and on the basis of the under-cloud surface temperature reconstruction, simulating the intraday change trend of the surface temperature by using the DTC model, and solving the daily average temperature through an integration means. According to the method, the surface temperature missing value caused by cloud shielding can be reconstructed, meanwhile, the systematic deviation that the average daily average temperatureis higher than that of real daily average temperature in traditional four times of instantaneous observation can be effectively corrected, and daily average temperature products which are continuous in time and space are obtained. The method is high in applicability, can be used for rapid production of large-range remote sensing earth surface daily uniform temperature products, and can meet the requirements of actual production.

Owner:NANJING UNIV

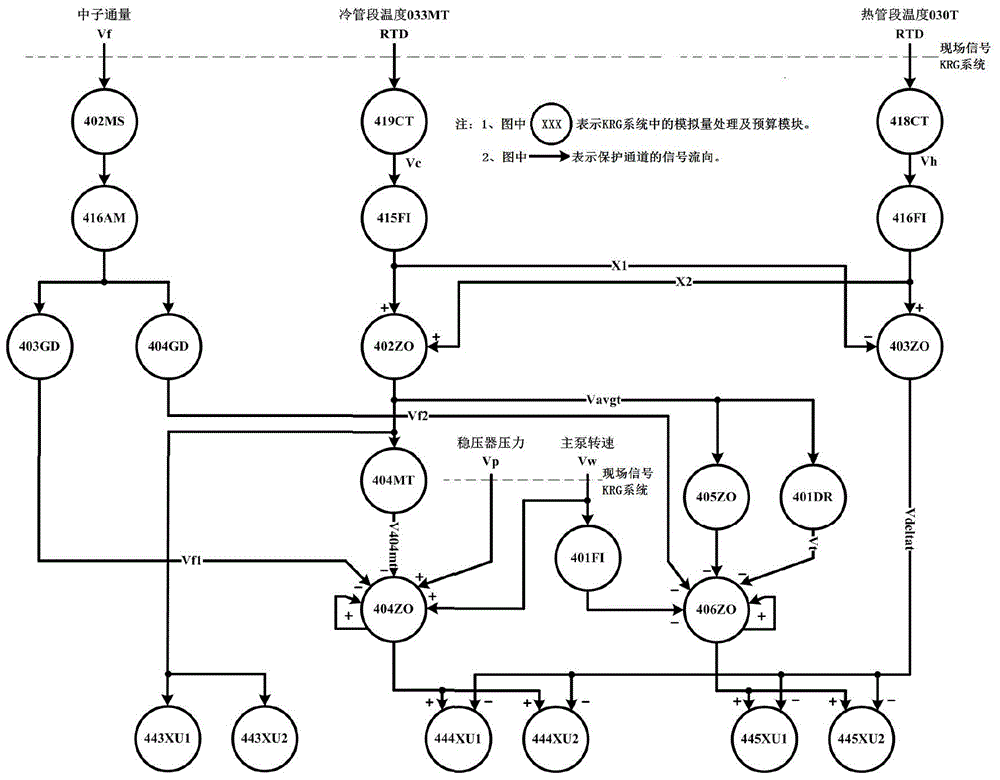

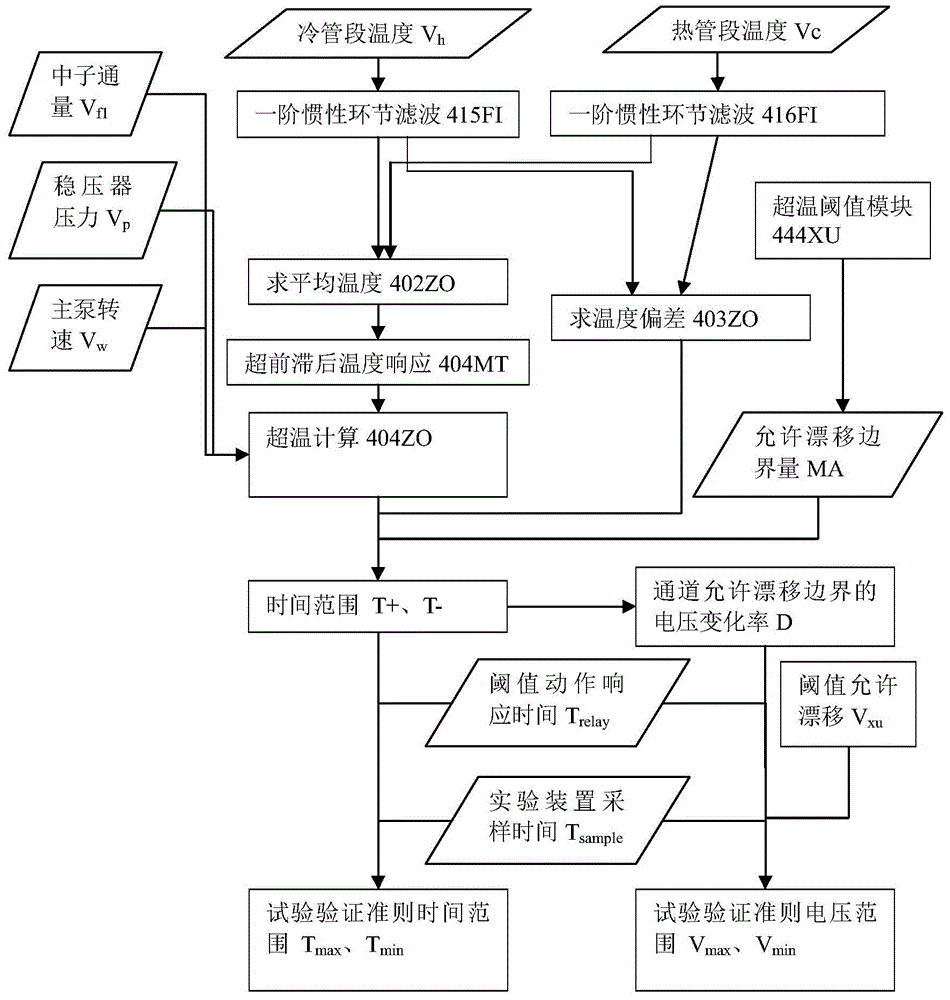

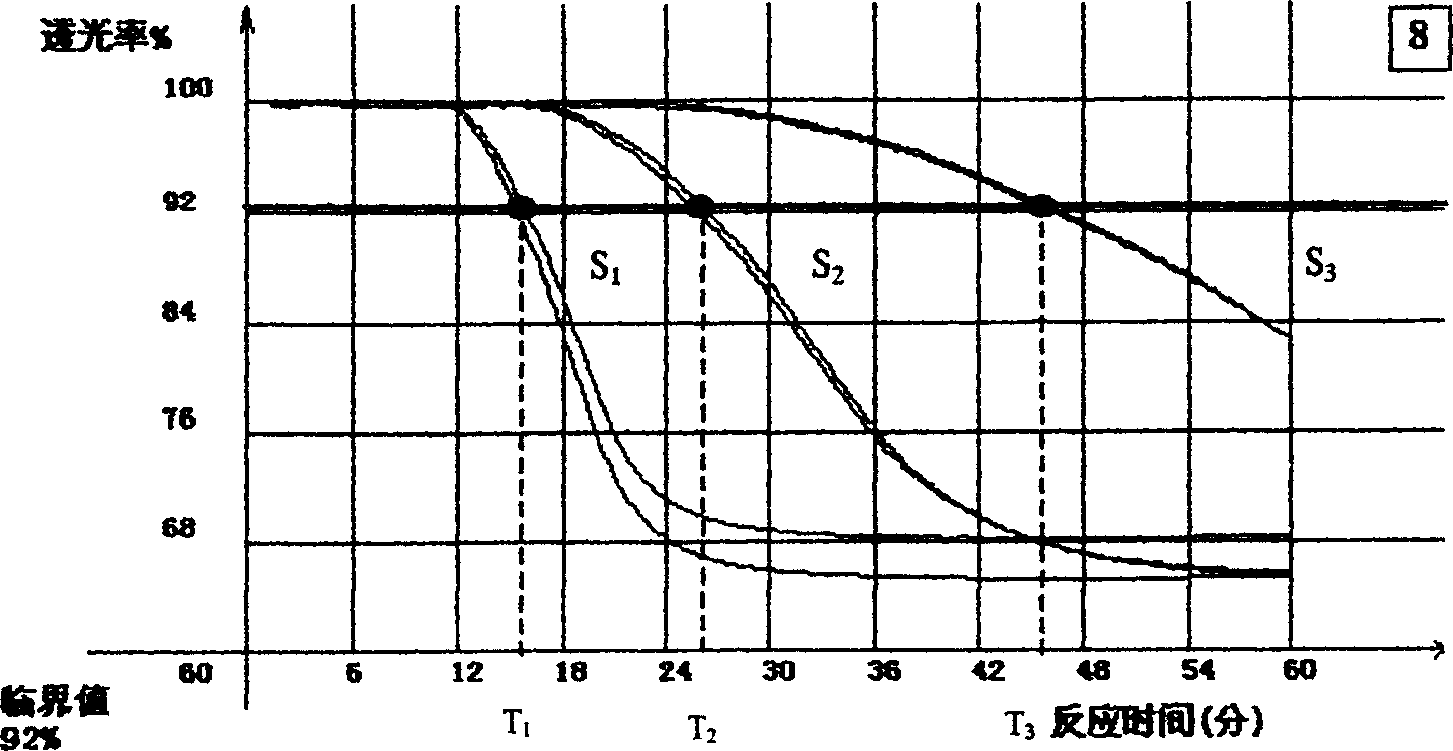

Tuning method for verification criterion of periodic test of overtemperature and overpower circuit protection channel of nuclear power plant

ActiveCN105321588AEasy to set upReasonable simulation of accident conditionsPower plant safety arrangementNuclear energy generationTime domainTime range

The invention provides a tuning method for a verification criterion of a periodic test of an overtemperature and overpower circuit protection channel of a nuclear power plant. The method comprises the steps of: according to an accident working condition, simulating an accident working condition signal collected from a site; obtaining a function of an input voltage obtained by calculation of a threshold value module in a time domain in the accident working condition; when the input voltage reaches a threshold value voltage, triggering the threshold valve module in the accident working condition to act; and then obtaining a time range and a voltage range, in which the accident working condition is triggered to act according to systematic deviation of the whole protection channel: Tmax, Tmin and Vmax, Vmin, thereby providing the verification criterion of the periodic test of the overtemperature and overpower circuit protection channel of the nuclear power plant.

Owner:CHINA TECHENERGY +1

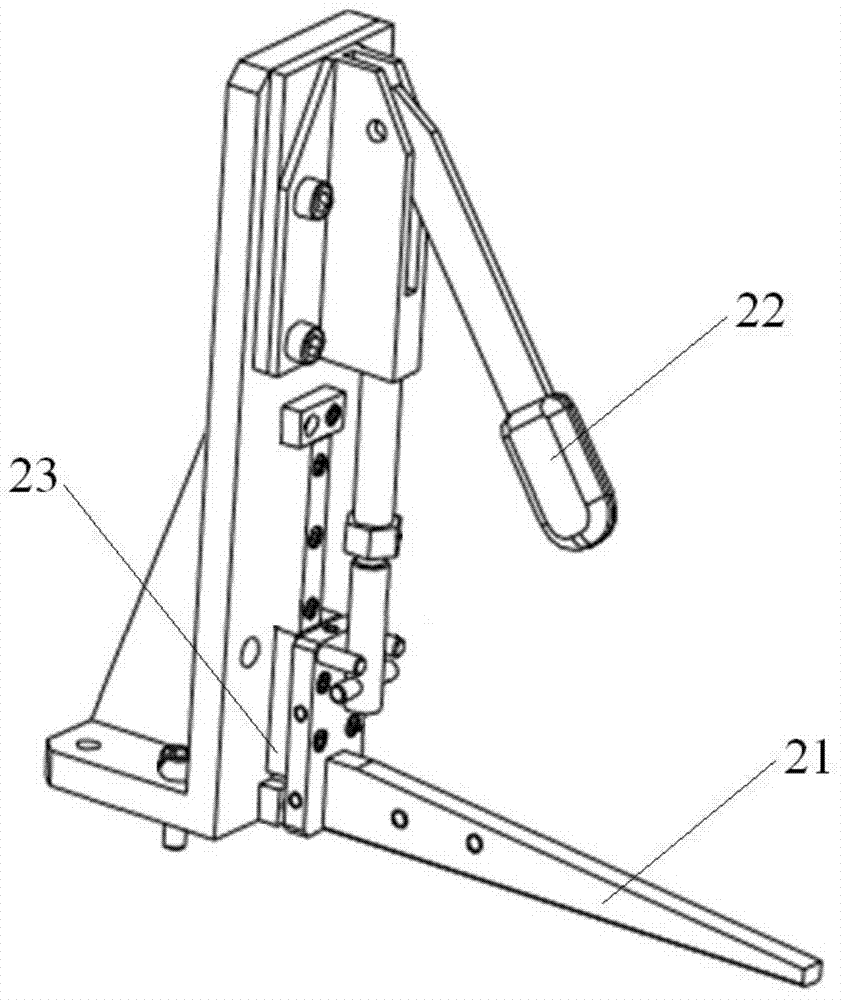

Radian testing device for battery diaphragm

ActiveCN104279936AReduce biasImprove test accuracyMechanical counters/curvatures measurementsRead throughSystematic deviation

The invention discloses a radian testing device for a battery diaphragm. The radian testing device comprises a test table, a tension mechanism, a radian measuring scale, two sets of compression mechanisms and two locating blocks. The two sets of compression mechanisms are arranged at the two ends of the test table respectively, the two locating blocks are arranged beside the two sets of compression mechanisms respectively, the tension mechanism is arranged between the two compression mechanisms, and the radian measuring scale is arranged between the two sets of compression mechanisms. When the radian testing device is used, the diaphragm is paved on the test table and is located by the two locating blocks first, the two sets of compression mechanisms tightly compress the two ends of the diaphragm respectively, the tension mechanism presses the diaphragm to provide simulation tension for the diaphragm, and then the radian is read through the radian measuring scale. The measuring principle of forming one line through two points is adopted, the systematic deviation is small, and the test precision is improved. In addition, the tension mechanism simulates the practical situation, so that the measured radian has more reference significance. The uniform measuring device is adopted for testing the radian of the diaphragm, the uncertain factors caused by artificial participation are few, and therefore, the measuring accuracy is improved while the measuring efficiency is increased.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Method and system for reducing interference caused by phase noise in radar system

ActiveCN108603928ASuppression of Phase Noise/Effect of Phase NoiseReduce computational costRadio wave reradiation/reflectionRadar systemsPhase noise

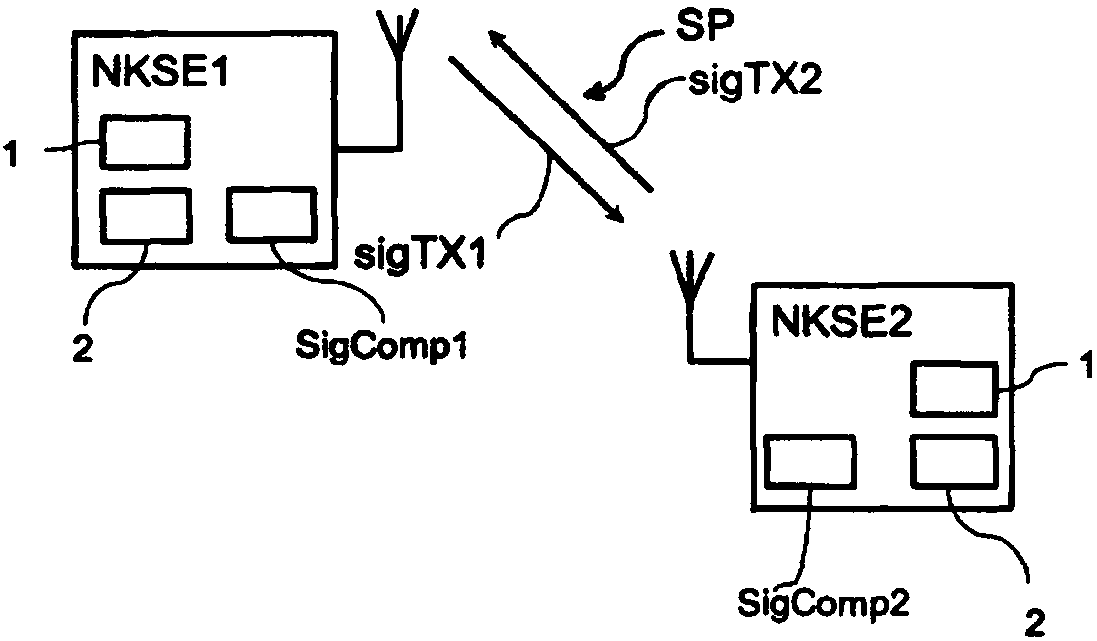

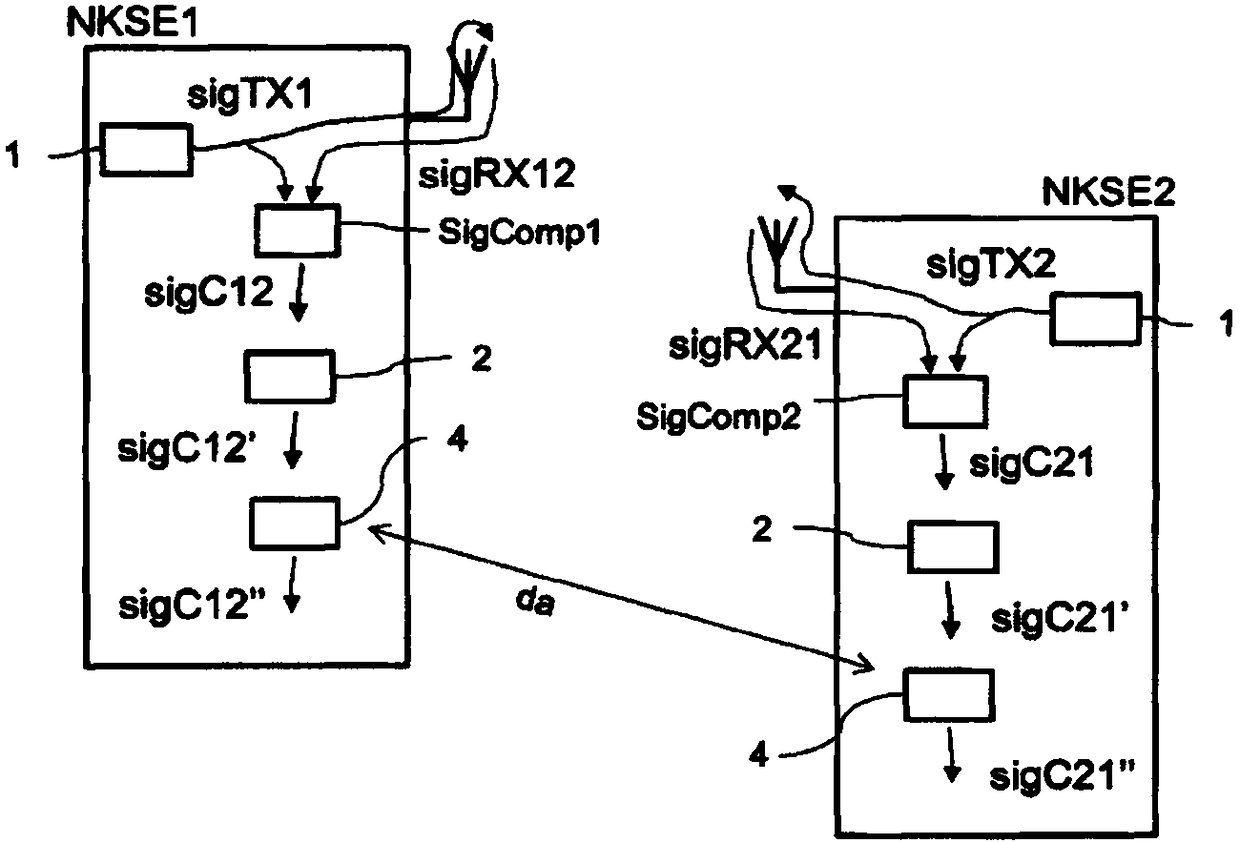

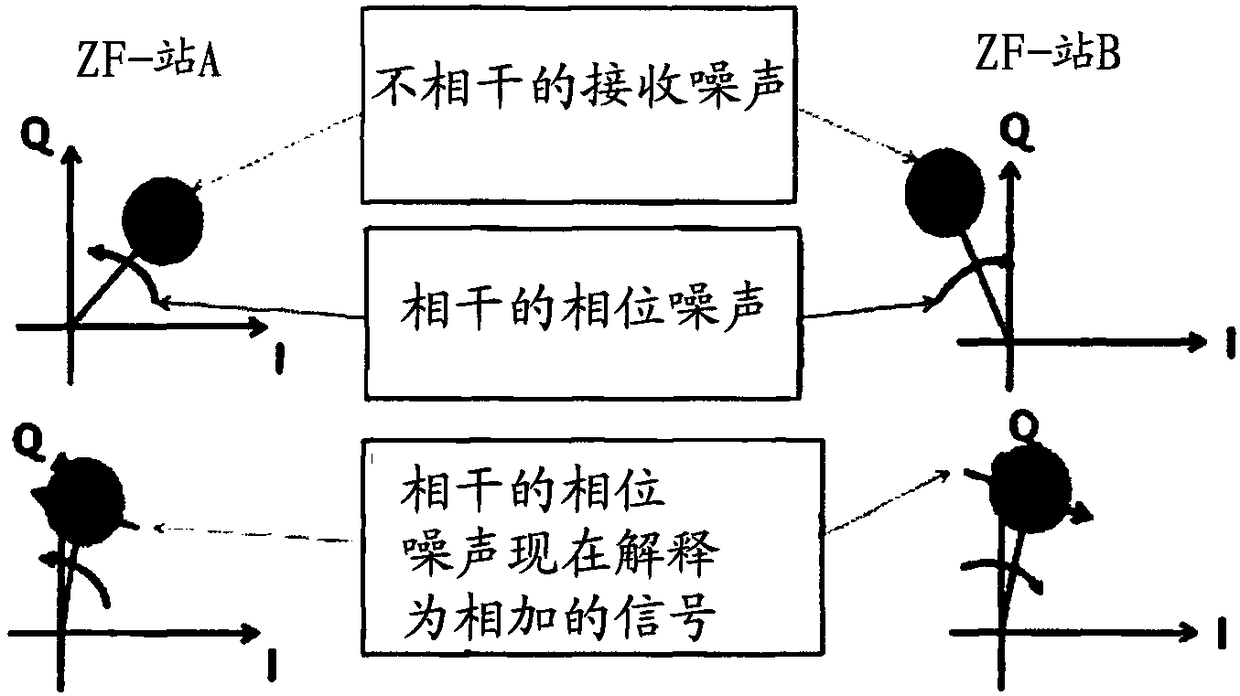

A method for reducing interference caused by phase noise in a radar system is described in particular, in which a first signal (sigTX1) is generated in a first non-coherent transceiving unit (NKSE1) and is transmitted, in particular emitted, via a path (SP), a first signal (sigTX2) is generated in a further, in particular second non-coherent transceiving unit (NKSE2) and is transmitted, in particular emitted, via the path (SP), the signals (sigTX1 and sigTX2) are directly or indirectly received in the respective other transceiving stations and are processed there as reception signals sigRX12 and sigRX21, a comparison signal (sigC12) is formed in the first transceiving unit (NKSE1) from its first signal (sigTX1) and from such a first signal (sigTX2) received from the further transceiving unit (NKSE2) via the path (SP), and a further comparison signal (sigC21) is formed in the further transceiving unit (NKSE2) from its first signal (sigTX2) and from such a first signal (sigTX1) receivedfrom the first transceiving unit (NKSE1) via the path (SP), wherein the further comparison signal (sigC21) is transmitted, in particular communicated, from the further transceiving unit (NKSE2) to thefirst transceiving unit (NKSE1), wherein in a first step deviations of the signals sigC21 and sigC12 which are caused by systematic deviations in the transceiving units (NKSE2, NKSE1) are compensatedfor, wherein in a second step at least one complex value from a first of the two comparison signals or from a signal which has been derived from this first comparison signal is used to adapt at leastone complex value of the second of the two comparison signals or a value of a signal which has been derived from this second comparison signal and to therefore form a signal (sigCC), wherein the adaptation is carried out using a mathematical operation to form the vectorial sum or the difference of the complex values or the sum or the difference of the phases of the complex values.

Owner:SYMEO

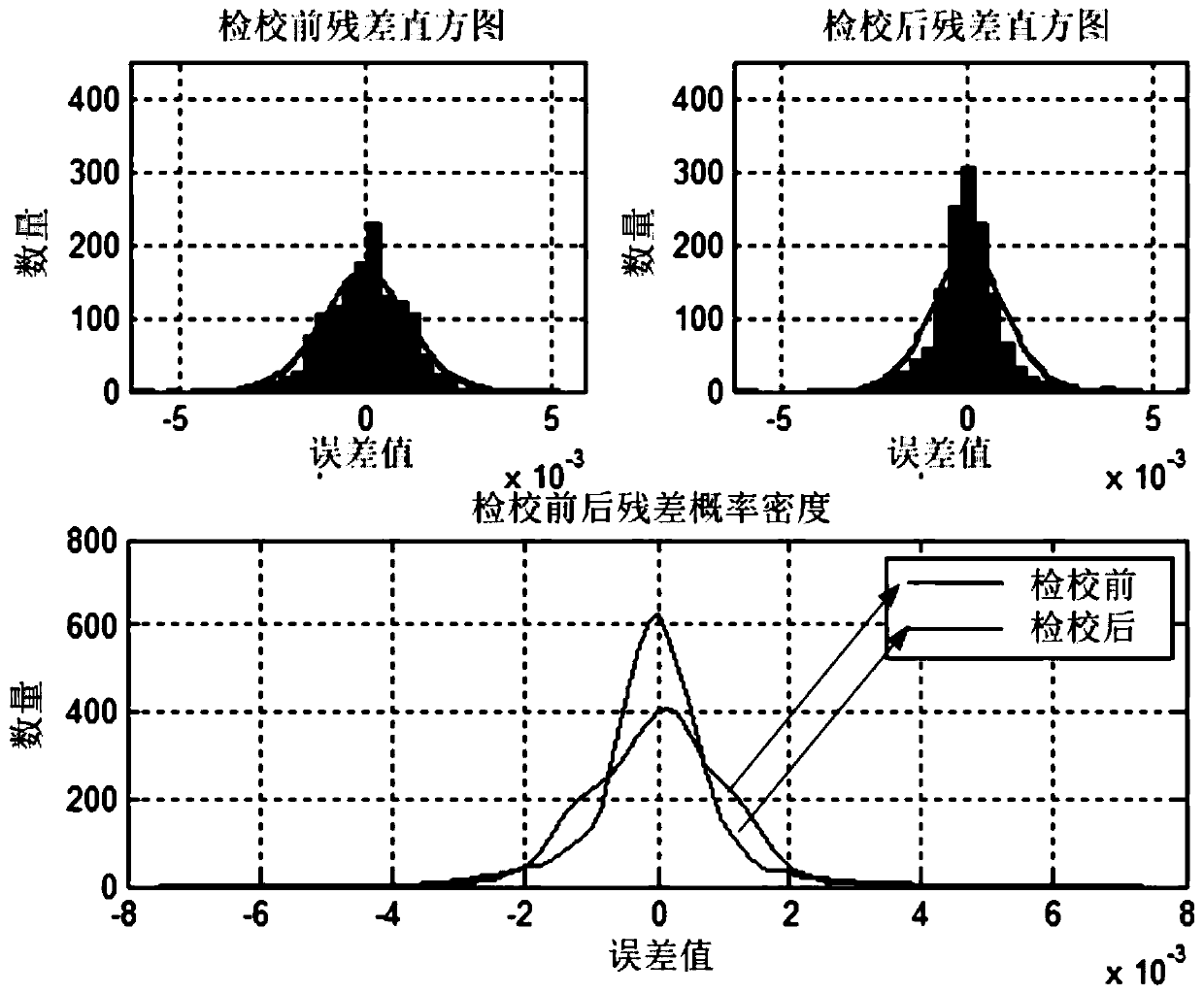

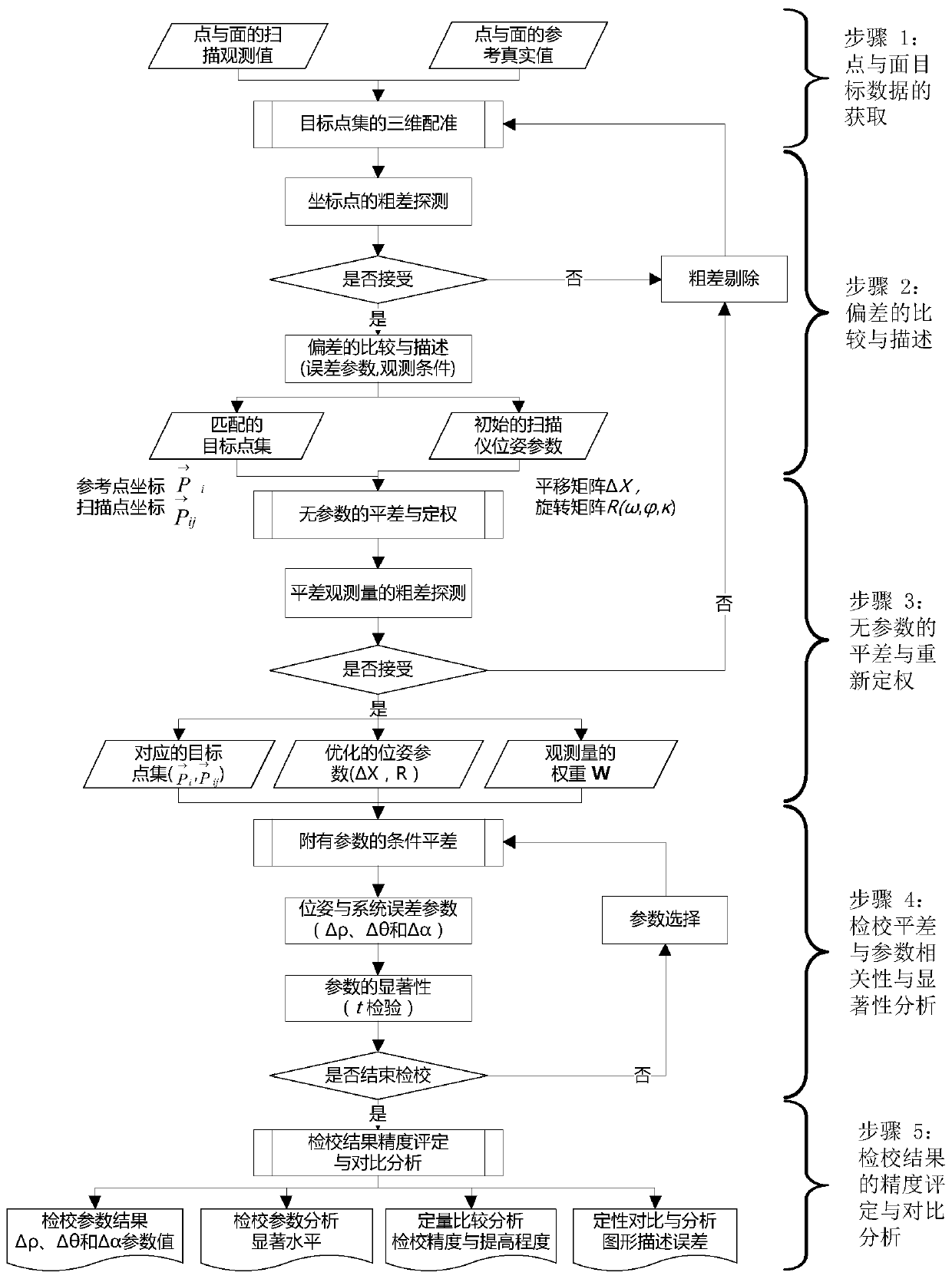

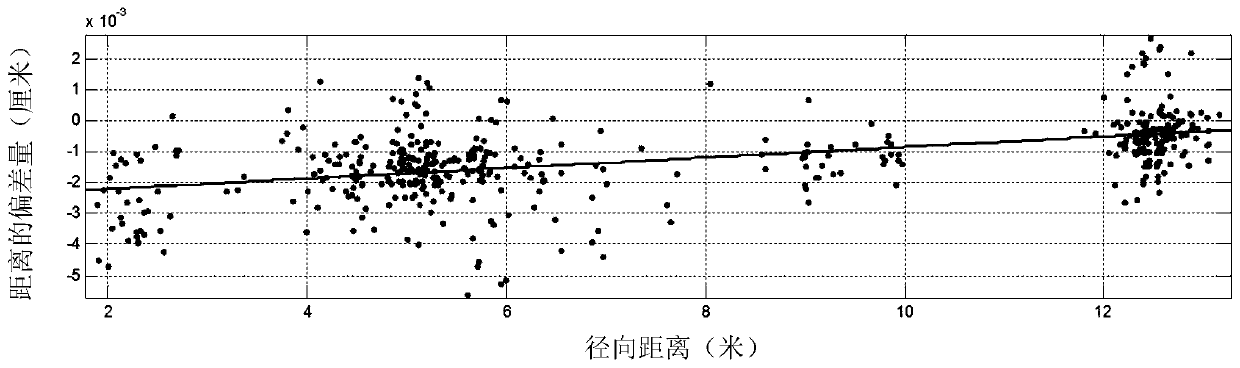

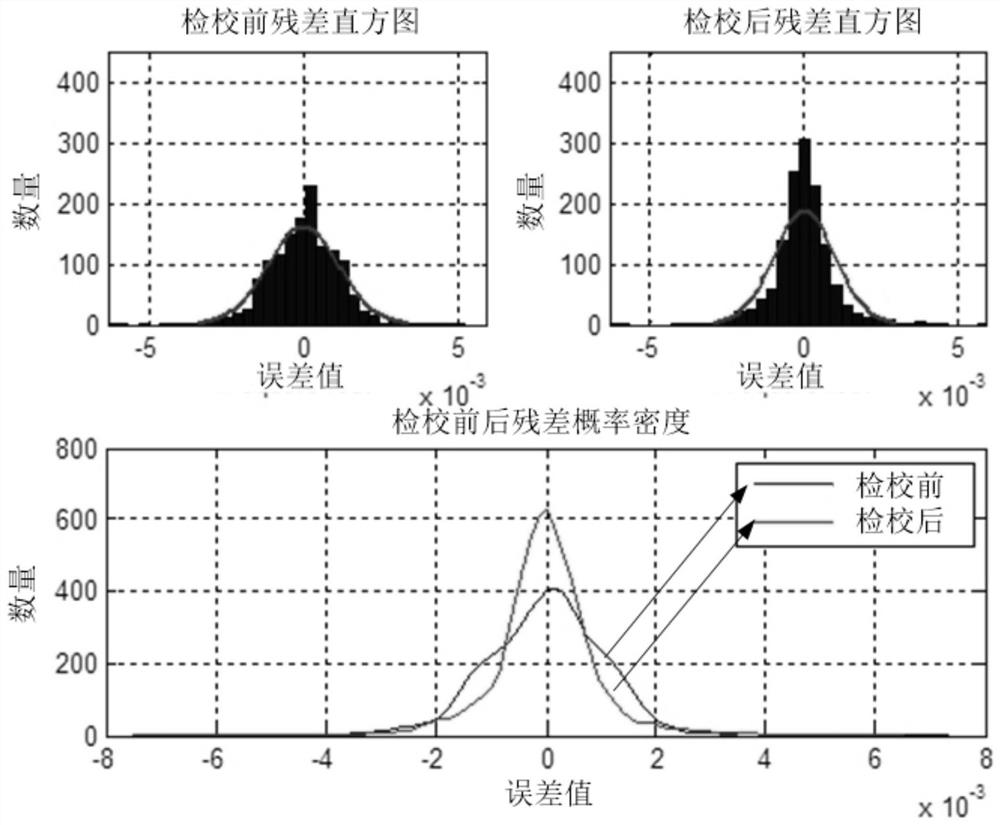

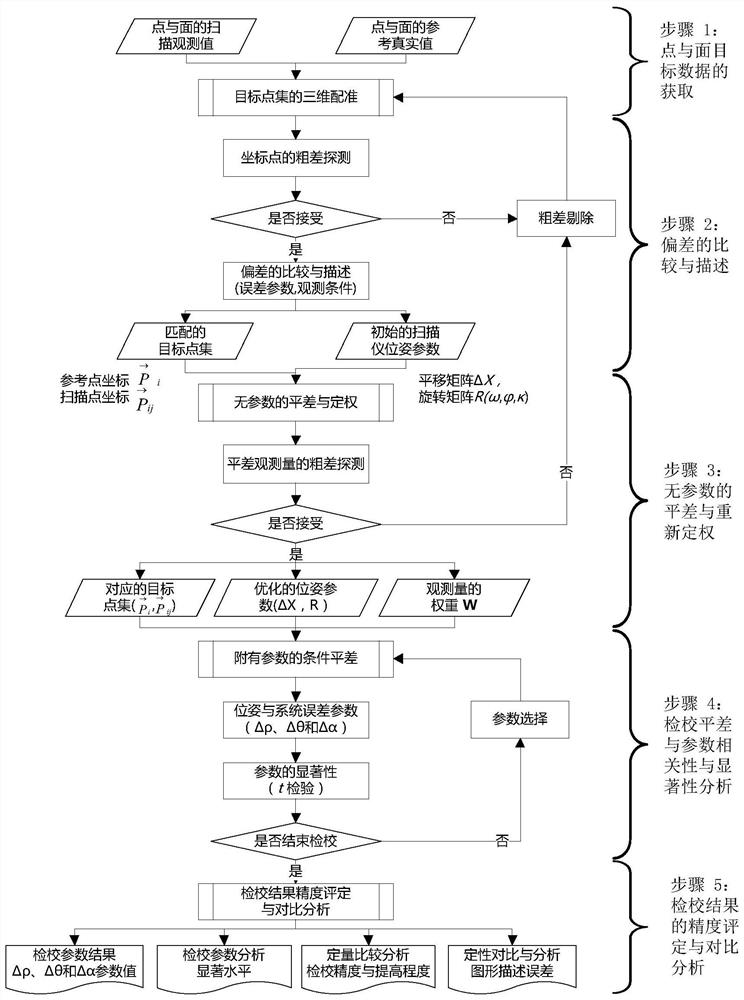

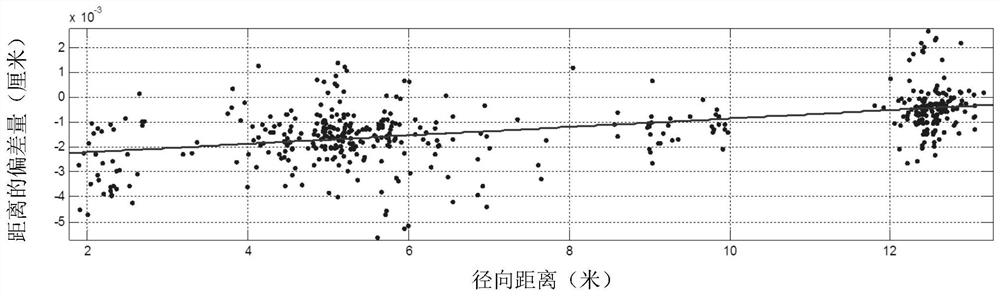

Three-dimensional laser scanning calibration method simultaneously constrained by point and surface characteristics

The invention relates to a three-dimensional laser scanning calibration method simultaneously constrained by point and surface characteristics. The method comprises the following steps of (1) acquiring scanning observation values and reference true values of point and surface targets and carrying out three-dimensional registration and gross error detection on two target point sets, (2) taking a registration conversion parameter as an initial pose parameter and describing a systematic deviation between an observed value and a reference value by adopting an error model, (3) setting a system error parameter to be zero and carrying out least square estimation on the system error parameter and the initial pose parameter to obtain an optimized pose parameter and an observed quantity weight, (4)performing optimal estimation on the system error parameter and the pose parameter by using a parameter condition adjustment model with parameters and with a point and a surface as constrain conditions, and (5) correcting the scanning observation value by using the estimated parameters, counting a deviation between the observation value and the reference value before and after correction by usingmathematics, and evaluating improvement precision and degree. Compared with an existing method, the method of the invention has the advantages that various constraints are integrated, all parameters are optimally estimated at the same time, the accuracy is good, the precision is high, and the operation is easy.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

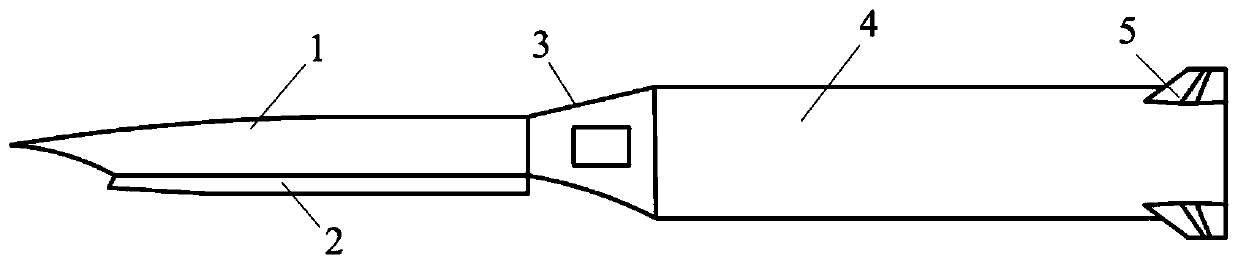

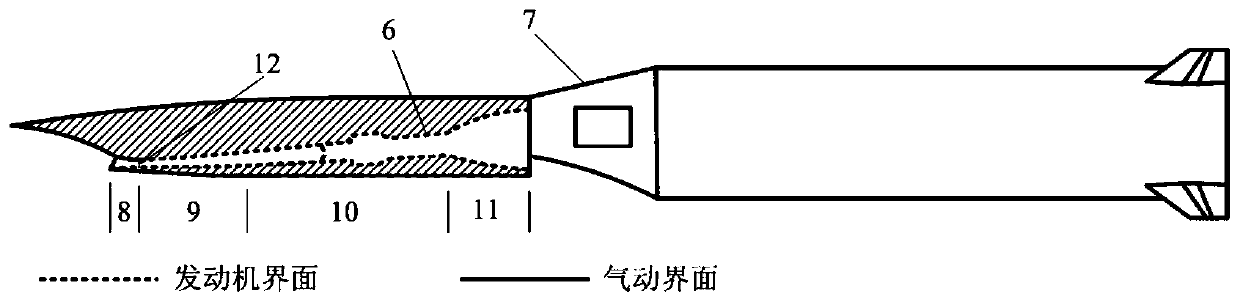

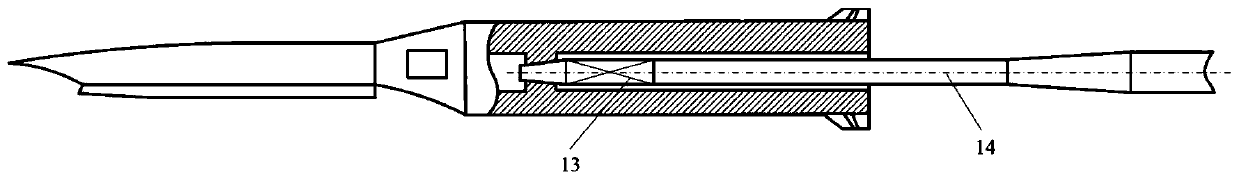

Method for obtaining thermal aerodynamic performance of flying aircraft

ActiveCN109900486ASolve the problem that the test is difficult to obtain thermal performanceImprove accuracyGas-turbine engine testingJet-propulsion engine testingThermal stateEngineering

The invention provides a method for obtaining thermal aerodynamic performance of a flying aircraft. Based on the idea of interface division, the whole flying aircraft interface is divided into an engine interface and an aerodynamic interface, cold aerodynamic performance data of the flying aircraft are superimposed on cold and thermal state difference of the engine interface and cold and thermal state difference of the pneumatic interface as thermal state aerodynamic performance of the flying aircraft, and a problem that thermal performance is difficult to obtain at present is solved in the prior art. The method is advantaged in that data accuracy is guaranteed by wind tunnel test data as a baseline, moreover, cold and thermal state difference of the engine interface and cold and thermal state difference of the pneumatic interface instead of the absolute amount are obtained through CFD calculation, systematic deviation between CFD calculation and the test is avoided, and data accuracyis guaranteed.

Owner:BEIJING AEROSPACE TECH INST

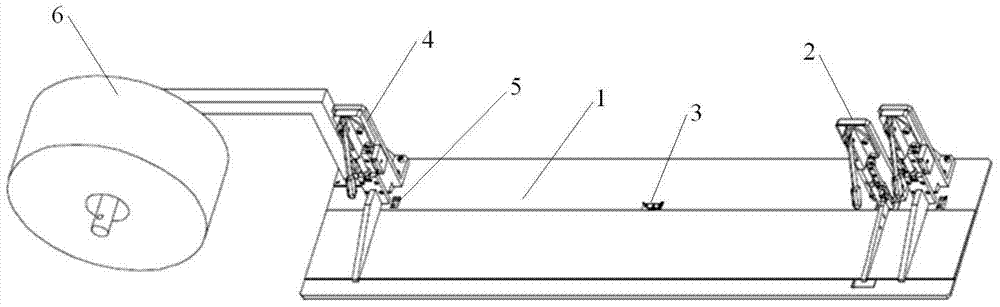

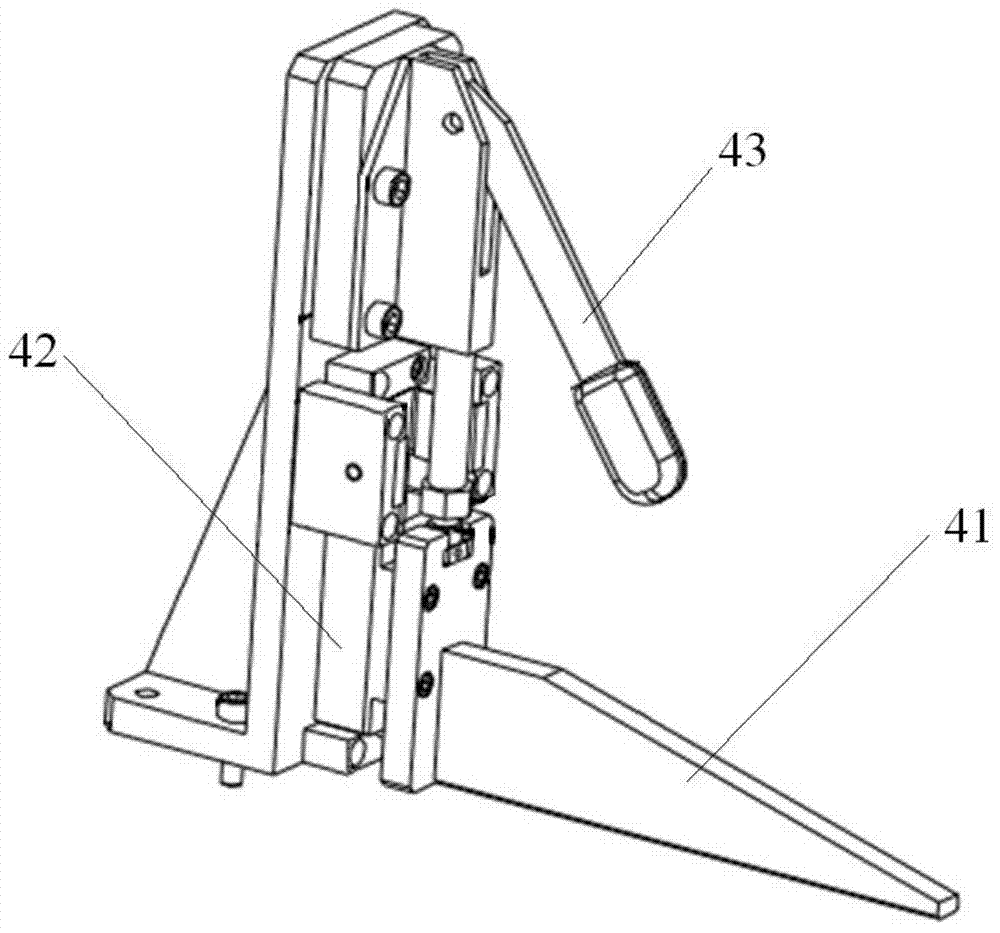

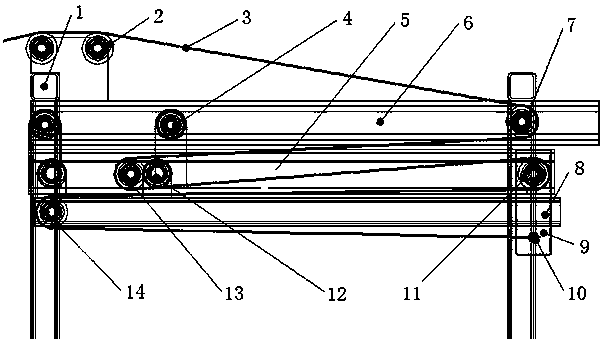

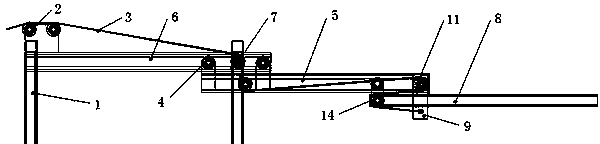

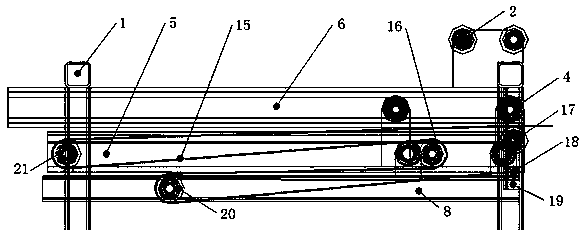

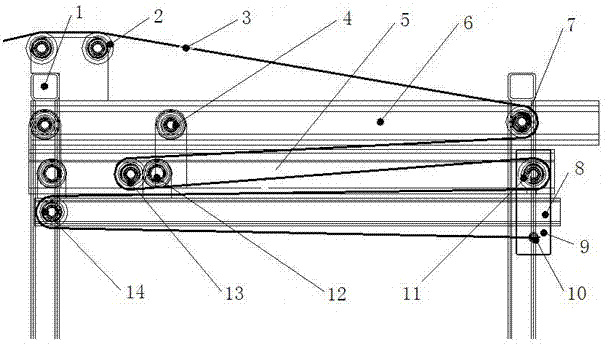

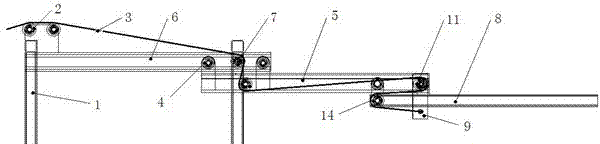

Mounting method for camera of picking machine and telescoping mechanism of camera

InactiveCN103363264AImprove coordinationImprove rationalityStands/trestlesBlock and tackleEngineering

The invention discloses a mounting method for a camera of a picking machine and a telescoping mechanism of the camera. The camera is mounted on a telescoping mechanism which can be folded up, and the position of the camera can be changed through the folding and unfolding of the telescoping mechanism, so as to realize visual gathering of a stand object. The telescoping mechanism mainly comprises the following components, namely a transmitting device, a machine rack, an electromotor, a machine rack cross beam, a section arm I, a section arm II and telescoping and guiding devices arranged on the two sides of the telescoping mechanism, and the telescoping and guiding devices, through the rotation of the electromotor, drive the length of the steel wire to change and realize space position change of the telescoping mechanism of the camera accordingly; the mechanism provided by the invention is convenient to operate, high in environmental adaptability, facilitates timely adjusting of systematic deviation between the mechanism and a camera connected there with, and is simple in structure, convenient to control and maintain, and high in practicability, and the replacement of the hydraulic oil tank with the pulley group greatly saves manufacturing cost. The mechanism can not only be applied to fruit picking machinery, but also be applied to small machinery utilizing telescoping mechanisms.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

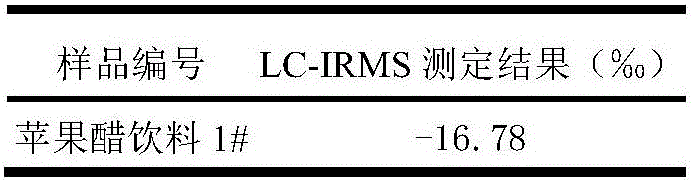

Method for determining acetic acid delta 13C value in fruit vinegar beverage

The invention discloses a method for determining acetic acid delta 13C value in a fruit vinegar beverage by using liquid chromatography-stable isotope ratio mass spectrometry, which belongs to the technical field of stable isotope analysis. The method comprises the following steps: 1) preparing an acidic mobile phase for a liquid chromatogram component; 2) adjusting the liquid chromatography-stable isotope ratio mass spectrometry to a work state; 3) determining the delta 13C value of the acetic acid in a known substance and a sample under the same condition; and 4) obtaining the delta 13C value of the acetic acid in the sample according to the systematic deviation of an apparatus. The method has the characteristics of simple operation, convenient calculation, and stable and accurate determination (the determination standard deviation is only 0.01%), and provides the assistance for promoting a stable isotope technology in adulteration detection of a fruit vinegar beverage product and is good for safety of food in our country.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Design method of composite sample store and its system

InactiveCN1948559AEfficient integrationLibrary screeningBioinformaticsComposite sampleComputer science

The invention offered a method to design combined library of samples, which facilitated people to reduce the frequency of sample experiments and increase effective amount of information in fixed frequency of sample experiments by applying acquired knowledge and given assumption extremely. The steps of this method were as follows: (1) Many components to compose samples were supplied. (2) Variables were offered for each component, which were sampled at intervals. (3) At least one constraint condition was set for at least one variable. (4) Pseudo-samples were produced. (5) Pseudo-samples were checked to confirm whether they were qualified samples. (6) Steps (4) and (5) were repeated until at least one qualified sample was found. The method of this invention was efficient and accurate, which could avoid system deviation in sample design.

Owner:YASHENTECH CORP

Method for measuring delta 13C values of benzoic acid in milk in online manner

The invention discloses a method for measuring delta 13C values of benzoic acid in milk in an online manner, particularly relates to methods for applying liquid chromatograms-stable isotope ratio mass spectra to measuring delta 13C values of benzoic acid in milk in an online manner, and belongs to the technical field of stable isotope analysis. The method includes steps of 1), selecting appropriate liquid chromatographic columns; 2), preparing acidic mobile phases; 3),adjusting liquid chromatograms-stable isotope ratio mass spectra until the liquid chromatograms-stable isotope ratio mass spectra are in work states; 4), adjusting the concentration of benzoic acid in samples; 5), automatically injecting the samples by the aid of an automatic sample injector and measuring measured delta 13C values of the benzoic acid; 6), correcting measurement systematic deviation of instruments by the aid of reference materials with known delta 13C values; 7), computing the delta 13C values of the benzoic acid according to the systematic deviation. The method has the advantages of simplicity in operation, convenience, low detection limit and stable results. Besides, dependence on manual sample injection operation can be prevented, and the delta 13C values can be continuously analyzed for 24 h.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Wheat output predication method based on revised regional climate mode data

ActiveCN102722766BImprove forecast accuracyImprove unityComplex mathematical operationsPredictive methodsSystematic deviation

Owner:NANJING AGRICULTURAL UNIVERSITY

A method for detecting fixed tire frame markings based on step-by-step conversion of spatial coordinate data

InactiveCN104048654BHigh marking accuracyImprove work efficiencySurveying instrumentsOther workshop equipmentTheodoliteTotal station

The invention discloses a fixed molding bed scribing monitoring method based on a total station. The method provides two coordinate orientation mode and two scribing patterns. The method comprises the following steps: according to design requirements of a fixed molding bed, establishing a spatial three-dimensional coordinate system of a fixed molding bed area along original points, an X-axis direction or a Y-axis direction; automatically calculating the horizontal angle and the vertical angle of a position where a to-be-scribed point is located in virtue of space coordinate matching techniques and directing the total station to carry out automatic scribing, or directing operating personnel to carry out manual scribing; carrying out automatic correction on deviation occurred in measurement of the to-be-scribed point until systematic deviation setting requirements are met; and carrying out three-dimensional coordinate measuring and checking on the scribed fixed molding bed. The invention has the following beneficial effects: compared with traditional fixed molding bed scribing methods based on a steel tape, a theodolite and a range finder, the method provided by the invention only needs two persons for operation on the spot and has the characteristics of high scribing precision, a high degree of automation, high work efficiency, high security, etc.

Owner:JIANGSU MARITIME INST

Mounting method for camera of picking machine and telescoping mechanism of camera

InactiveCN103363264BImprove coordinationImprove rationalityStands/trestlesBlock and tackleEngineering

The invention discloses a mounting method for a camera of a picking machine and a telescoping mechanism of the camera. The camera is mounted on a telescoping mechanism which can be folded up, and the position of the camera can be changed through the folding and unfolding of the telescoping mechanism, so as to realize visual gathering of a stand object. The telescoping mechanism mainly comprises the following components, namely a transmitting device, a machine rack, an electromotor, a machine rack cross beam, a section arm I, a section arm II and telescoping and guiding devices arranged on the two sides of the telescoping mechanism, and the telescoping and guiding devices, through the rotation of the electromotor, drive the length of the steel wire to change and realize space position change of the telescoping mechanism of the camera accordingly; the mechanism provided by the invention is convenient to operate, high in environmental adaptability, facilitates timely adjusting of systematic deviation between the mechanism and a camera connected there with, and is simple in structure, convenient to control and maintain, and high in practicability, and the replacement of the hydraulic oil tank with the pulley group greatly saves manufacturing cost. The mechanism can not only be applied to fruit picking machinery, but also be applied to small machinery utilizing telescoping mechanisms.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

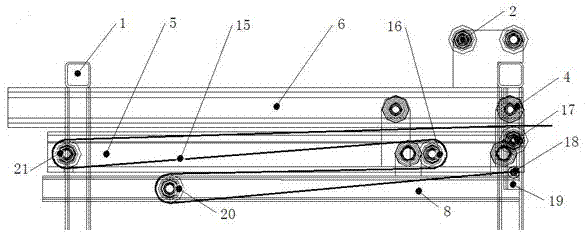

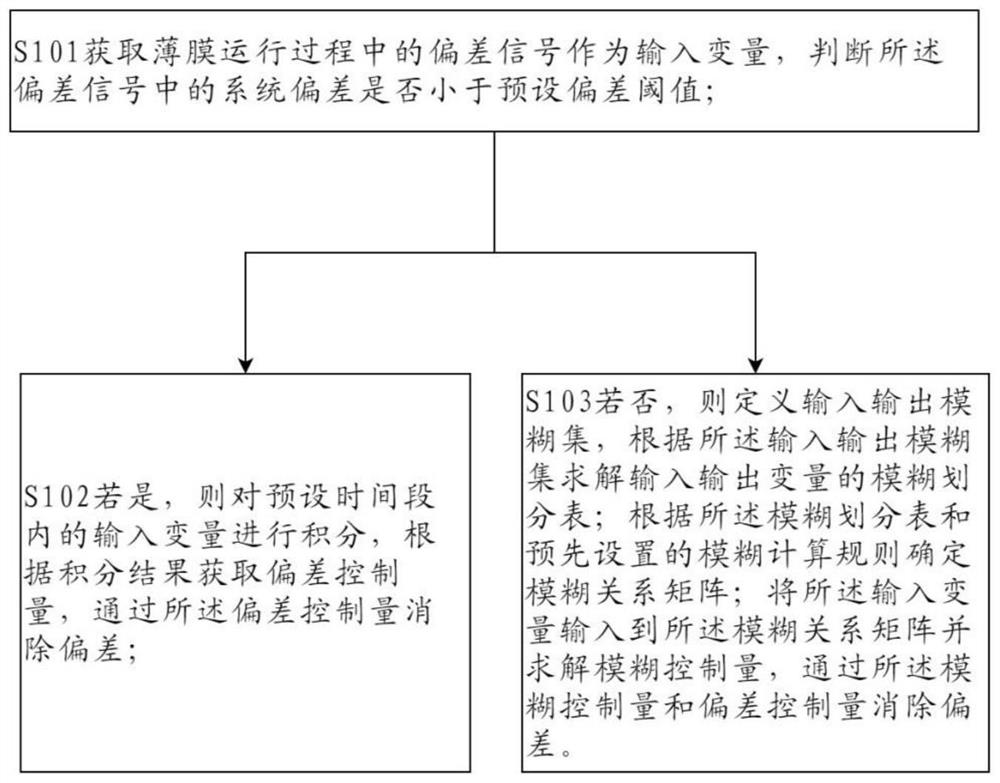

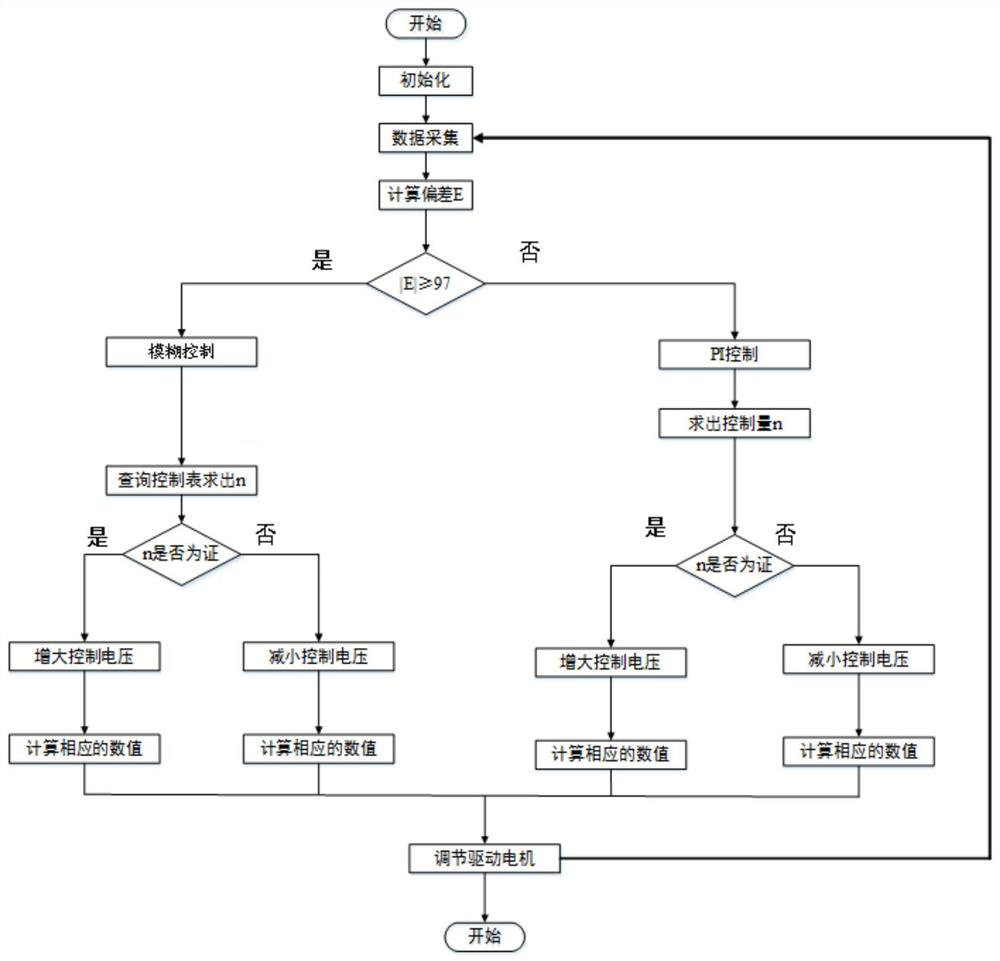

Method and device for controlling parallelism of thin film in imprinting equipment

PendingCN114153139AImproved parallelism control stabilityImprove control stabilityPhotomechanical apparatusNanotechnologyFuzzy computingControl engineering

The invention provides a film parallelism control method and device in imprinting equipment, and the method comprises the steps: obtaining a deviation signal in the operation process of a film as an input variable, and judging whether the system deviation in the deviation signal is smaller than a preset deviation threshold value or not; if yes, integrating the input variables in a preset time period, obtaining a deviation control quantity according to an integration result, and eliminating deviation through the deviation control quantity; if not, defining an input and output fuzzy set, and solving a fuzzy division table of the input and output variables according to the input and output fuzzy set; determining a fuzzy relation matrix according to the fuzzy division table and a preset fuzzy calculation rule; inputting the input variable into the fuzzy relation matrix, solving the fuzzy control quantity, and eliminating the deviation through the fuzzy control quantity and the deviation control quantity. Errors continuously generated in the operation process of the thin film are calculated through the fuzzy algorithm, accumulated errors caused by control quantity calculation through a mathematical formula are effectively eliminated, and parallelism control stability is improved.

Owner:TIANJIN EMBEDTEC

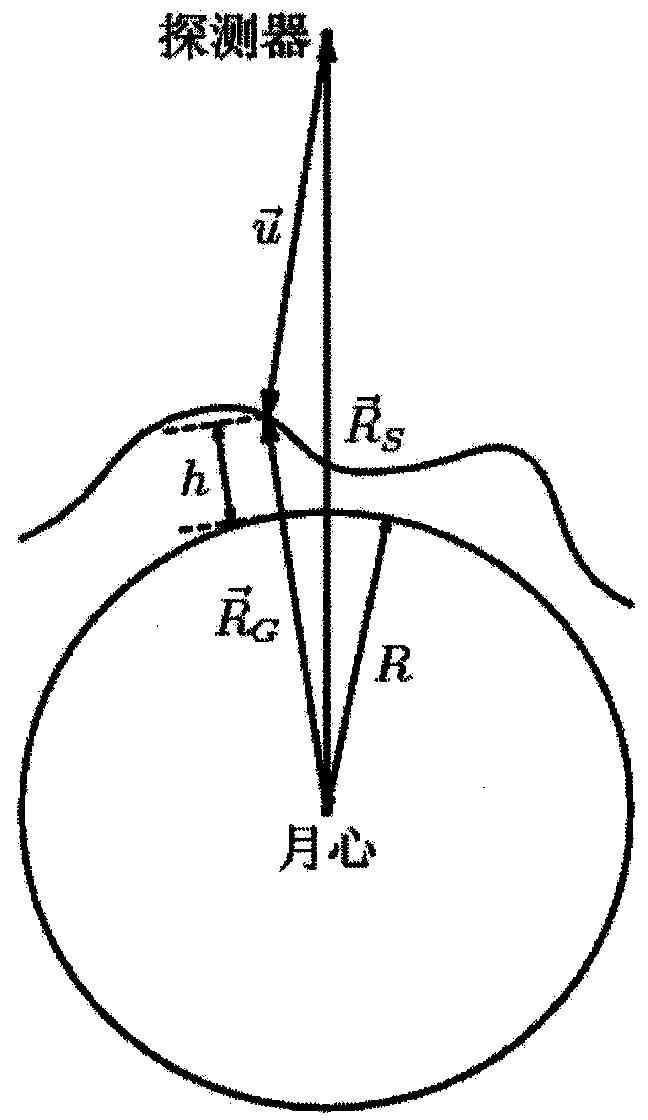

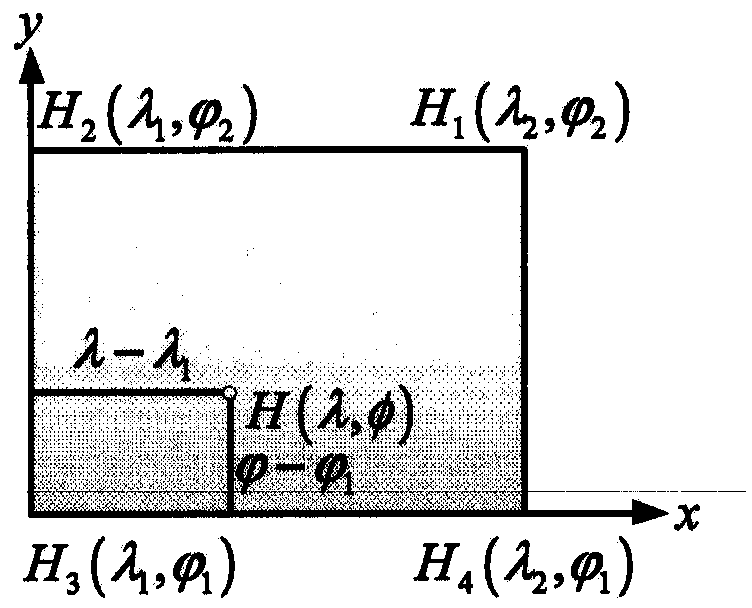

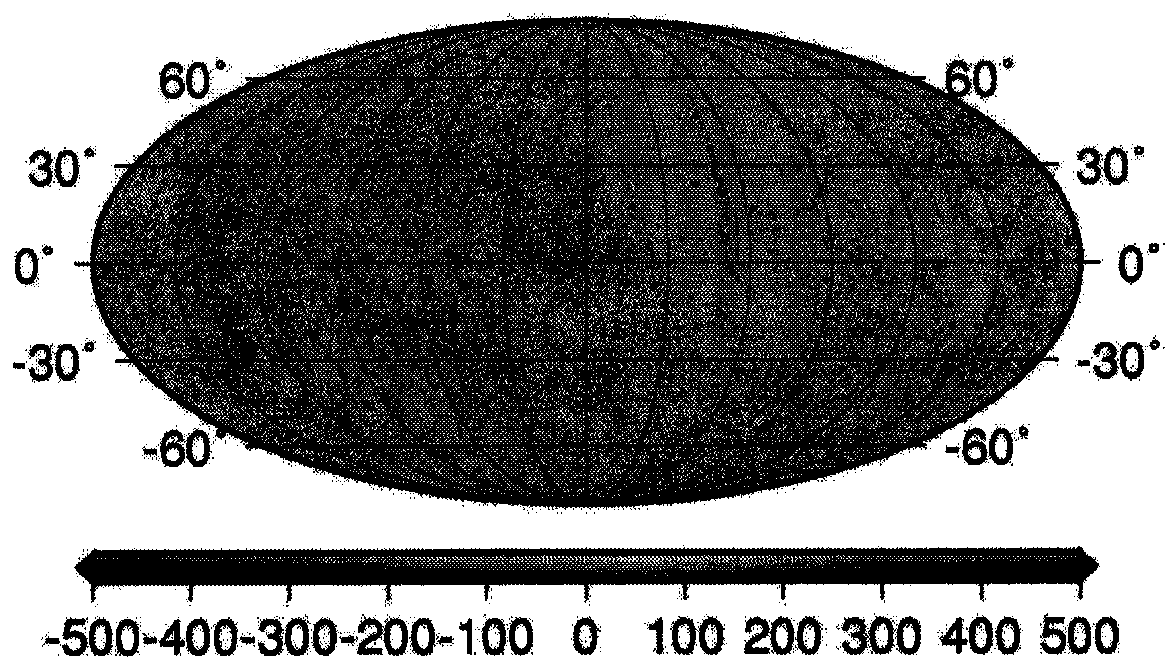

Method for calibrating moon elevation model by utilizing selenographic laser reflection array coordinate

ActiveCN104614730AAccurate acquisitionEliminate systematic biasElectromagnetic wave reradiationSystematic deviationLaser

The invention discloses a method for calibrating moon elevation model by utilizing selenographic laser reflection array coordinate; the method comprises the following steps: using laser height measurement data to establish a moon elevation model; calculating a selenographic laser reflection array precise elevation value; calculating a systematic deviation average value of the moon elevation model; correcting the deviation of the moon elevation model. By utilizing the technical scheme, the systematic deviation of the elevation model can be effectively removed, and the moon elevation model can be precisely obtained.

Owner:中国人民解放军63920部队

Homologous system model method for quantitatively detecting bacterial endotoxin of blood

InactiveCN1217191CEliminate distractionsEnhanced inhibitory effectColor/spectral properties measurementsBiological testingMathematical modelInterference factor

The present invention relates to homologous system model method for quantitatively detecting bacterial endotoxin of blood, and aims at solving the problem of difference or interference caused by different system property. In the system model method, one new concept is proposed for solving the BET interference of the sample, i. e., all the unkown interference factors are considered as systematic deviation. Once the systematic deviation is eliminated, the said BET interference of the sample will be eliminated. In some reaction system, digital model is established and sample is detected in the same system, the difference caused by different system property will be eliminated.

Owner:湛江安度斯生物有限公司

A Calibration Method of 3D Laser Scanning Constrained by Point and Surface Features Simultaneously

ActiveCN110672031BWave based measurement systemsUsing optical meansAlgorithmTransformation parameter

The invention relates to a three-dimensional laser scanning calibration method constrained by point and surface features at the same time, comprising the following steps: (1) Obtaining scanning observation values and reference real values of point and surface targets, and three-dimensional registration of two target point sets and gross error detection; (2) Use the registration conversion parameters as the initial pose parameters, and use the error model to describe the systematic deviation between the observed value and the reference value; (3) Set the system error parameters to zero and the initial pose parameters Perform least squares estimation to obtain optimized pose parameters and weights of observations; (4) Conditional adjustment with parameters constrained by points and surfaces to optimally estimate system error parameters and pose parameters; (5) Use the estimated parameters to correct the scanning observations, use mathematical statistics to correct the deviation between the observations and the reference values before and after correction, and evaluate the accuracy and degree of improvement. Compared with the existing method, the present invention has the characteristics of synthesizing multiple constraints, simultaneously optimally estimating all parameters, good accuracy, high precision and easy operation.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com